Specifications

- Thickness: 50~150mm.

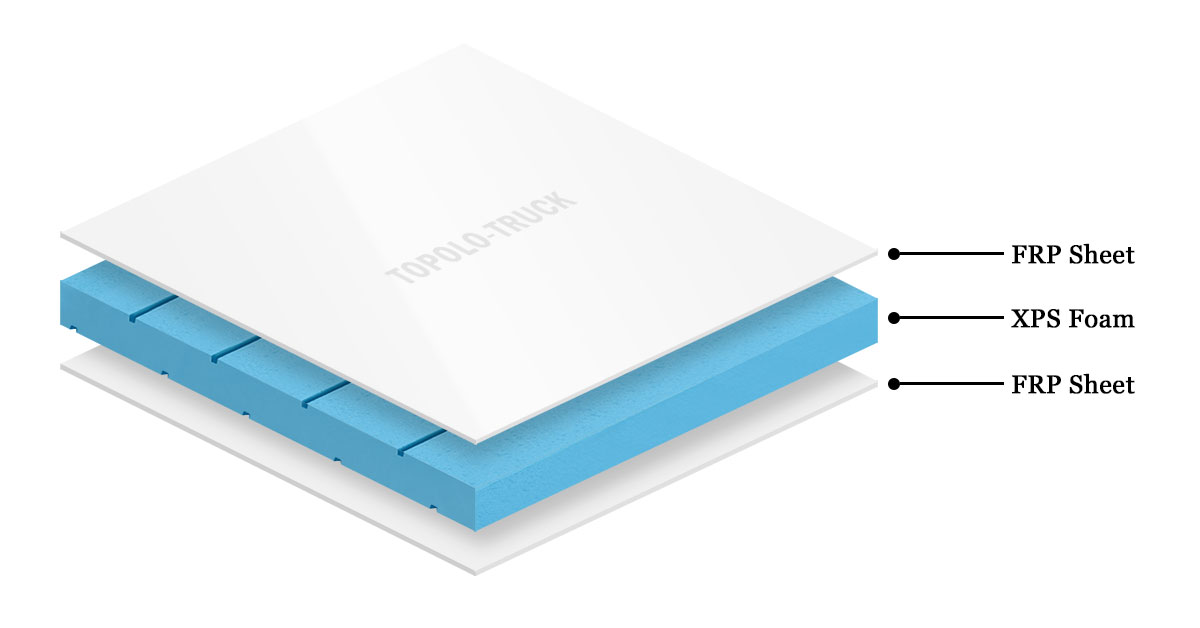

- Top Facing: Glossy FRP sheet. (Thickness: 0.7~5.0mm)

- Core Materials: XPS (Extruded Polystyrene) foam. (Density: 35~50kg/m³)

- Bottom Facing: Glossy FRP sheet. (Thickness: 0.7~5.0mm)

- Width: Max 3.2m.

- Length: Max 12m.

DESCRIPTION

The market often demands more from refrigerated truck bodies used to transport temperature-sensitive goods, and our fiberglass reinforced plastic (FRP) faced extruded polystyrene (XPS) foam sandwich panels provide the perfect combination of strength, insulation and performance. Whether you are transporting fresh produce, pharmaceuticals or other temperature-sensitive commodities, our panels will ensure that your goods are delivered in optimal condition every time.

Panel Advantages

- High strength-to-weight ratio.

- Good thermal insulation.

- Long service life.

- Good weather resistance.

Application Areas

- Frozen meat transportation.

- Cold chain logistics.

- Pharmaceutical transportation.

- Fresh produce distribution.

- Multi-temperature zone temperature-controlled freight.

Expert in Box Body Composite Panels

TOPOLO-TRUCK has developed a series of high-quality composite panels for box truck and trailer bodies. Our composite panels are designed to perfectly combine strength, quality, aesthetics and environmental protection requirements, which can help you improve the durability, safety and transportation efficiency of your trucks. We use industry-leading materials and technologies to carefully build and provide the best solutions for your vehicle projects, and provide high-quality products that meet strict standards and exceed customer expectations.