Home >> Truck Bodies

Refrigerated Truck Bodies

Expert in Customized Refrigerated Truck Body Solutions

TOPOLO-TRUCK

Building Better Refrigerated Truck Bodies

What Advantages Can We Offer Our Clients?

Make Your Brand More Competitive in The Market

☑ Lightweight Design

– Reduced Operating Costs

The TOPOLO-TRUCK refrigerated truck body is made of fiberglass composite panels, which are 30%–40% lighter than traditional metal foam panels. This innovation significantly reduces vehicle weight, effectively saving fuel and transportation costs.

☑ High Strength

– Increased Payload

Every part of the compartment (such as the walls, floor, and roof) uses precisely dimensional, seamless panels. This seamless design not only improves load-bearing capacity but also provides excellent resistance to rain, acids, alkalis, and dust. Furthermore, it offers high fire resistance and UV protection, ensuring cargo safety.

☑ Thermal Insulation

– Improved Refrigeration Efficiency

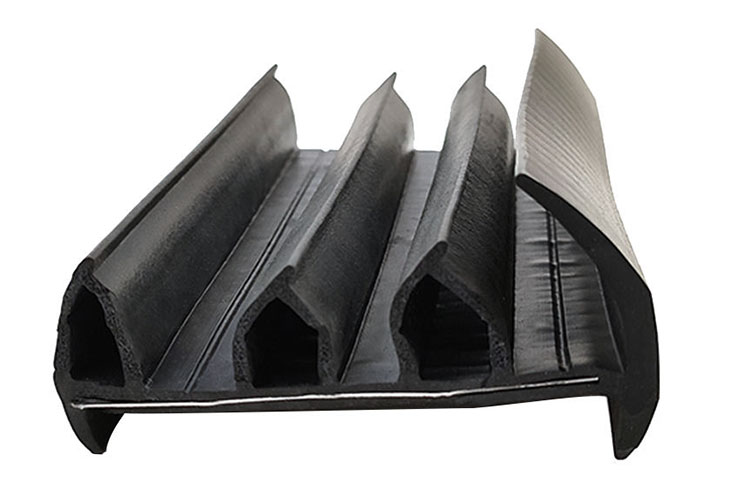

The low thermal conductivity insulation core composite panels, combined with aluminum alloy profiles, EPDM sealing strips, and waterproof adhesives, ensure superior sealing and thermal insulation performance. This provides a more efficient operating environment for the refrigeration unit.

☑ Reliable and Durable

– Long Service Life

TOPOLO-TRUCK’s refrigerated truck body design ensures durability, with an average service life of 10 to 15 years or even longer, guaranteeing a long-term return on investment.

☑ Aesthetically Pleasing Design

– Enhances Corporate Image

The modern and minimalist design not only meets functional requirements but also enhances the company’s image and strengthens the brand’s competitiveness in the market.

☑ Environmentally Friendly

– Sustainable and Green

TOPOLO-TRUCK’s refrigerated truck bodies are designed with sustainability in mind, using eco-friendly materials that reduce carbon emissions and the environmental impact.

Serving The Cold Chain Industry

We customize various types of refrigerated boxes for the cold chain industry to meet the application requirements of different industries.

These refrigerated boxes are widely used for transporting various perishable goods such as fruits and vegetables, meat and seafood, ice cream, cold drinks, milk, and other food products. At the same time, they are also used for transporting products that require special temperature control, such as pharmaceuticals, biological products, sensitive chemicals, as well as flowers and plants. Additionally, these refrigerated containers ensure that high-precision products, such as semiconductors, maintain a stable temperature during transportation to avoid damage.

Serving the Global Market

Provide efficient supply chain support for global enterprises

Currently, our refrigerated trucks are exported to many countries in CKD (Completely Knocked Down), SKD (Skimmed Craft), or CBU (Completely Built-up Unit) kit form. Our partners are located in North America, South America, South Korea, Japan, Southeast Asia, Europe, the Middle East, Australia, and other countries and regions. We will tailor the most cost-effective and reasonable solutions for our clients based on the specific market conditions of each region.

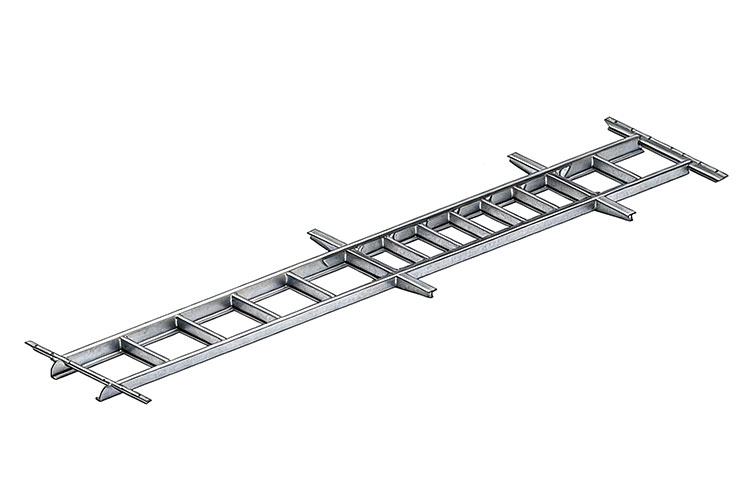

High-efficiency Assembly Box Body

- Fewer operators required.

- Easy to operate even for non-professionals.

- Simple installation tools.

- Smaller footprint.

- Low maintenance and repair costs.

We are committed to making the building of refrigerated truck bodies simpler and easier. All CKD or SKD kits are produced on the high-precision production line of our factory and assembled and inspected by experienced engineers. After being transported to the destination by container, the operator can quickly assemble it according to the installation instructions we provide. The entire installation process does not require complex installation tools, only basic lifting equipment and tools such as electric drills, hammers, wrenches, etc. Even unskilled operators can complete the assembly task, and skilled operators can even achieve an efficient productivity of 1 person 1 day 1 vehicle.

Common Size for Refrigerated Truck Bodies

(Customized According to Requirements)

We customize box bodies for all kinds of cold chain trucks: fresh-keeping trucks, refrigerated trucks, and frozen trucks. Sizes range from 10ft, 11ft, 12ft, 14ft, 15ft, 16ft, 18ft to 20~32ft or even longer. Whether it is a semi-trailer, large, medium, small, or miniature refrigerated truck, we will design a reasonable and reliable design plan for you. (For the convenience of transportation, most of the refrigerated bodies are shipped in CKD.)

Dimensions (External)

| Size (Length x Width x Height) | Load Capacity (Ton) |

| 4.2 x 1.8 x 1.8m | 1.5 |

| 4.2 x 1.8 x 1.85m | 2 |

| 5.8 x 2.1 x 2.2m | 3 |

| 6.2 x 2.0 x 2.0m | 5 |

| 7.4 x 2.2 x 2.2m | 5 |

| 9.6 x 2.3 x 2.7m | 25 |

| 12.5 x 2.4 x 2.7m | 28 |

Box Body Panels for Refrigerated Trucks

Integrated composite panels comprehensively enhance the performance of refrigerated truck bodies

In the initial design of our refrigerated truck box, we fully considered how to keep the body strong and not easily deformed, so in the selection of materials, we chose stronger and thicker materials than ordinary boxes. Before production, we will conduct strict tensile, compressive, peeling, high temperature and low-temperature resistance tests on the box material, and conduct CAE (Computer Aided Engineering) analysis; after the complete production of the refrigerated box, we will also do insulation, Waterproof, impact and other tests.

- Skin Layer

The skin material used as the composite panel is FRP, CFRT(Thermoplastic FRP). We will choose suitable skin and core materials according to the specific requirements of customers for refrigerated vehicles.

- Insulation Layer

Use rigid closed-cell PU/XPS foam. These foams have polar thermal conductivity, which can effectively ensure the temperature balance in the box. They are also waterproof and corrosion-resistant, and have a service life of more than 15 years.

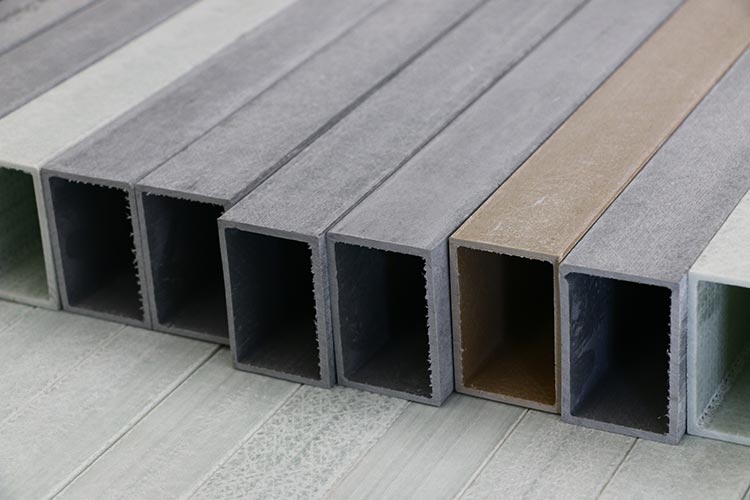

- Frame

In order to enhance the strength of thermal insulation, frame materials are usually embedded inside. These materials can be made of waterproof timbers, fiberglass profiles, etc. according to needs. These frame materials are characterized by high strength, waterproof, and can effectively reduce the problem of cold and heat bridges.

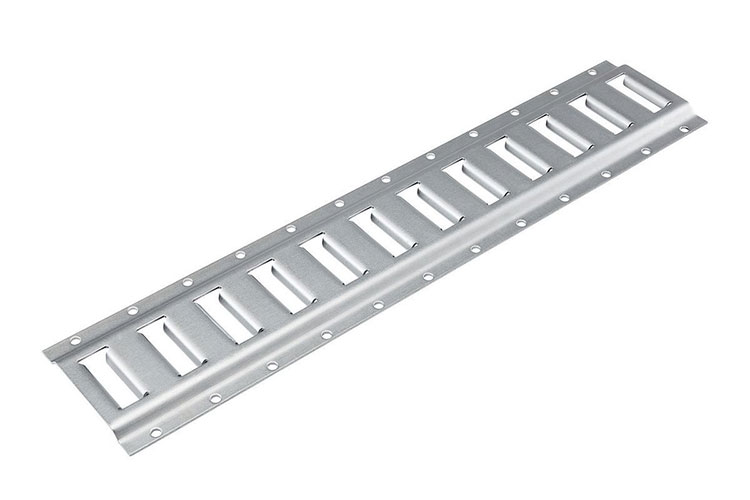

Custom Parts & Accessories for Refrigerated Boxes

We customize various standard and non-standard parts for refrigerated truck boxes, these parts include rear doors, side doors, door locks, hinges, frames, floors, skirting boards, meat hooks, sub-frames, bumpers, seal strips, mudguards, lights, curtains, refrigeration units and metal or plastic accessories.