Specifications

- Thickness: 50mm.(Customized: 20~150mm)

- Facing: 1.2 Gelcoat FRP sheet. (Customized: 0.7~5.0mm)

- Surface Color: RAL9001.

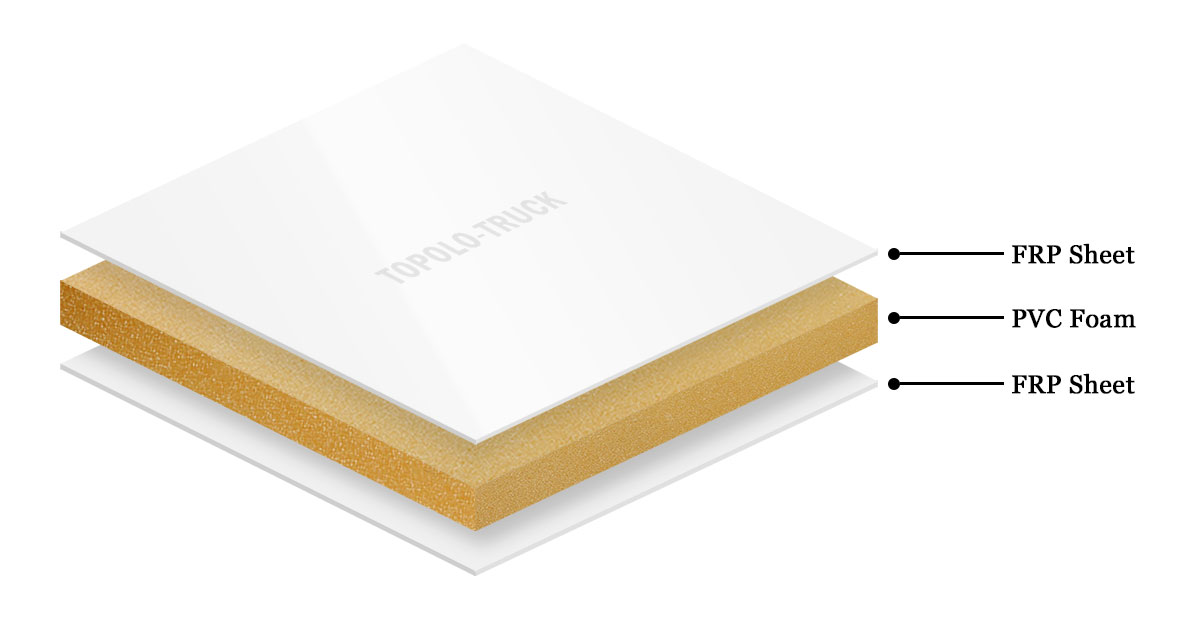

- Core Materials: 60kg/m³ PVC (Polyvinyl Chloride) foam.

- Width: Max 3.2m.

- Length: Max 12m.

- Internal Embedded Materials: Aluminum profiles, timbers.

- Flame Retardant Rating: B2.

DESCRIPTION

FRP skin PVC foam core composite panels are a high-performance material widely used in truck camper construction. This composite combines the advantages of glass-reinforced plastic (FRP) and closed-cell PVC foam core, offering strength, lightweight properties, and excellent insulation performance. The FRP skin is UV-resistant, corrosion-resistant, and weather-resistant, effectively protecting against damage in harsh weather conditions. Meanwhile, the PVC foam core provides superior thermal insulation due to its low thermal conductivity.

This composite material not only offers excellent rigidity and impact resistance but also significantly reduces the overall weight of the vehicle, enhancing fuel efficiency. Its exceptional corrosion resistance and long lifespan make it an ideal material for camper manufacturing. It is suitable for various vehicle body structures, including roofs, walls, and floors, ensuring the safety and comfort of the camper during transportation.

In addition, the manufacturing process of FRP skin PVC foam core composite panels is flexible, allowing for adjustments in thickness, surface treatment, and reinforcement to meet different environmental and usage requirements. This makes it suitable not only for truck campers but also for other types of vehicles, ships, and mobile devices, offering broader application prospects.

The design of this composite material focuses on sustainability and efficiency, meeting the modern camper industry’s strict requirements for safety, environmental friendliness, and comfort, making it the preferred material in the industry.