Specifications

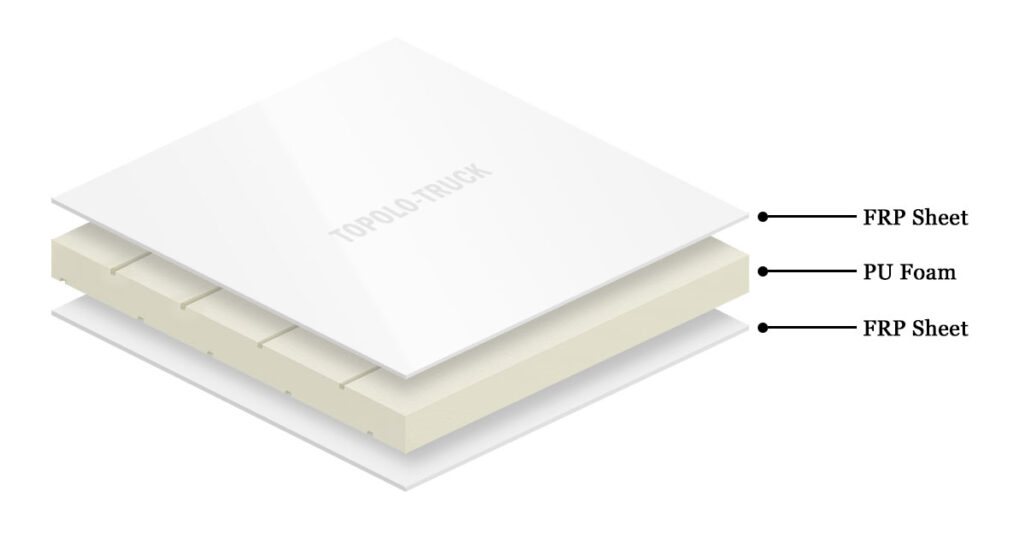

- Facing: Gelcoat FRP sheet. (Thickness: 0.7~5.0mm)

- Core Materials: PU (Polyurethane) foam. (Density: 28~50kg/m³)

- Width: Max 3.2m.

- Length: Max 12m.

- Thickness: 10~150mm.

DESCRIPTION

Our anti-ultraviolet FRP facing polyurethane foam insulation panels use closed cell polyurethane foam as the core material, which has excellent thermal insulation properties. This advanced material can maintain a consistent temperature in the refrigerated box, helping you improve energy efficiency and reduce refrigeration costs.

Structural Diagram

Advantages reflected

- Thermal Insulation

The polyurethane foam core has excellent thermal insulation properties, effectively maintaining the temperature difference inside and outside the container, reducing temperature fluctuations, and ensuring stable storage conditions to prolong the freshness of goods.

- Reducing Refrigeration Unit Energy Consumption

Due to its efficient insulation performance, the FRP polyurethane sandwich panel significantly reduces the amount of heat entering the refrigerated container, easing the load on the refrigeration unit, lowering energy consumption, and improving overall energy efficiency.

- Easy to Clean and Bacteria-Resistant

The FRP surface is smooth, resistant to dirt, UV rays, and corrosion, making it easy to clean and maintain. The polyurethane foam itself is also not prone to bacterial growth, providing a more hygienic environment for transported goods.

Advantages of UV-Resistant Gelcoat FRP

- UV-resistant gelcoat effectively prevents ultraviolet radiation from damaging FRP, avoiding aging, discoloration, or degradation of physical properties due to prolonged exposure to sunlight. This ensures that FRP maintains its stability and aesthetic appeal when used outdoors or in high-sunlight environments.

- The protective layer formed by the gelcoat enhances the weather resistance of FRP, allowing it to withstand harsh weather conditions such as high temperatures, humidity changes, and rain erosion, thus extending the product’s lifespan.

- The smooth surface of the UV-resistant gelcoat is less prone to dust and contaminants, making FRP products easier to clean and reducing the frequency of cleaning and maintenance.

- The gelcoat offers a variety of color options, making FRP products more visually appealing and suitable for high-end aesthetic applications.

- The gelcoat not only protects the FRP substrate from UV damage but also enhances the mechanical strength, impact resistance, and crack resistance of FRP, reducing the risk of damage from external impacts.

Expert in Truck Body Composite Panels

TOPOLO-TRUCK has developed a series of high-quality composite panels for box truck bodies. Our composite panels are designed to perfectly combine strength, quality, aesthetics and environmental protection requirements, which can help you improve the durability, safety and transportation efficiency of your trucks. We use industry-leading materials and technologies to carefully build and provide the best solutions for your vehicle projects, and provide high-quality products that meet strict standards and exceed customer expectations.