Specifications

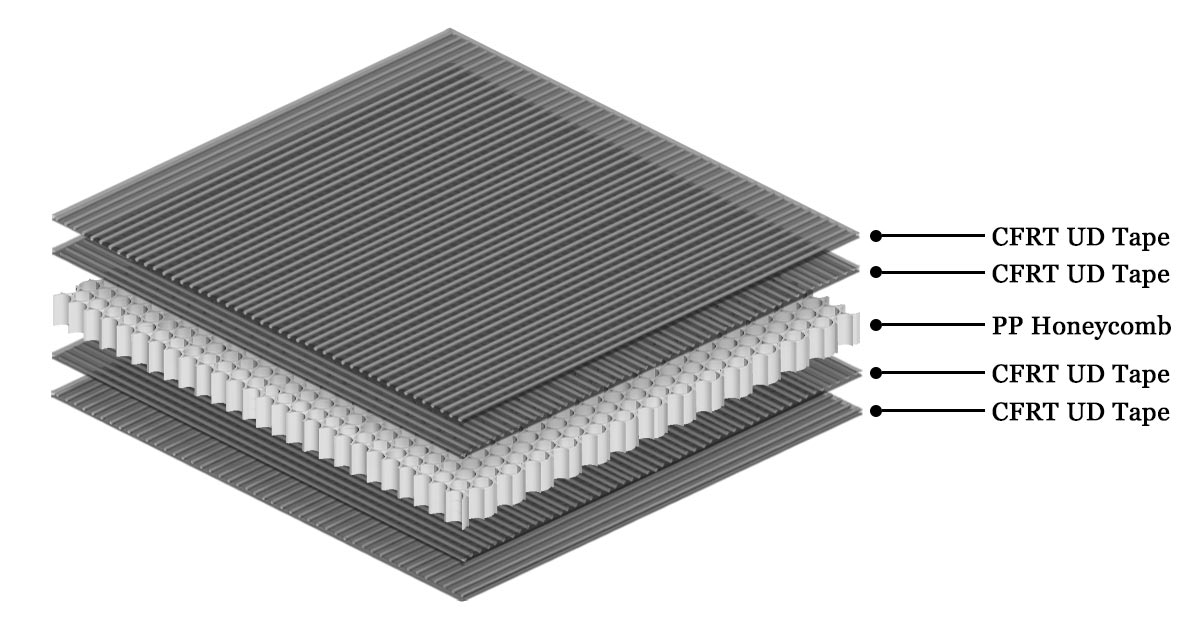

- Facing: CFRT Sheet. (Thickness: 0.7~2.0mm)

- Core Materials: PP (Polypropylene) honeycomb. (Density: 60~160kg/m³)

- Width: Max 2.8m.

- Length: Max 12m.

- Thickness: 10~50mm.

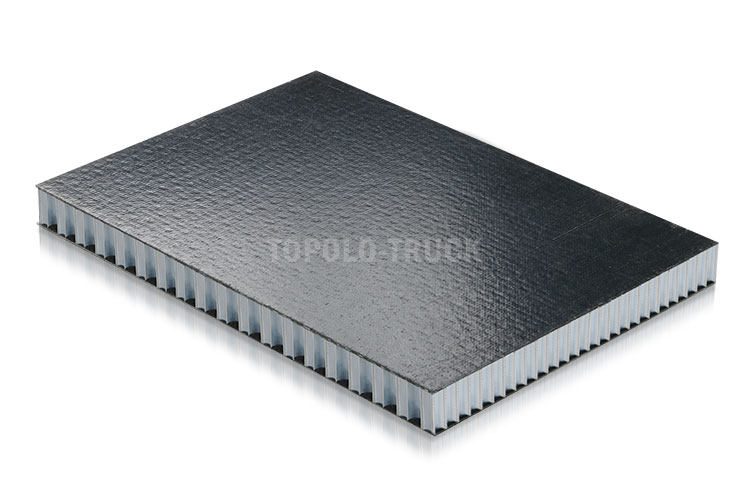

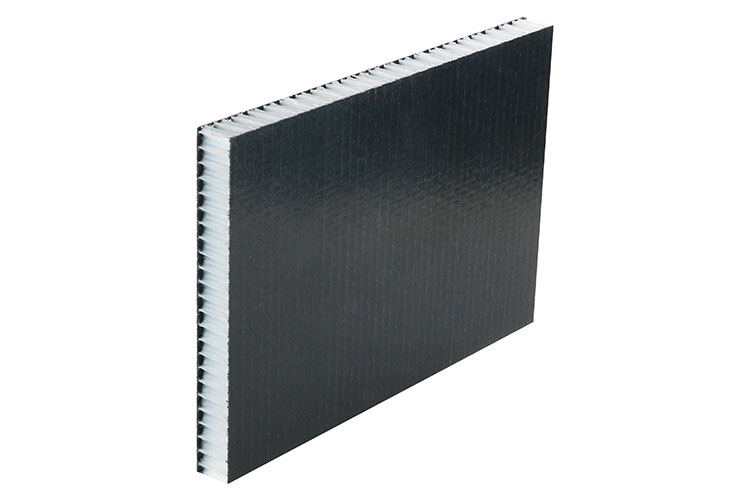

DESCRIPTION

Thermoplastic honeycomb composite panels are sandwich panels with CFRT (continuous fiber reinforced thermoplastic) composite sheets on the surface. Since no glue is used during the processing, the bonding between the layers is tighter and the structure is more stable.

Structural Diagram

Advantages of Thermoplastic Laminated PP Honeycomb Panels as Subflooring for Trailers

- Lightweight

The thermoplastic laminated polypropylene (PP) honeycomb panels offer a significant weight reduction compared to traditional materials. This helps in improving fuel efficiency for trailers and reduces overall vehicle weight, increasing payload capacity.

- Load-Bearing Strength

The honeycomb structure provides an excellent strength-to-weight ratio, offering robust support for the trailer’s structure while maintaining minimal weight. This allows for the safe transport of heavy loads without compromising the structural integrity of the trailer.

- Durability

These panels are resistant to water, corrosion, and deformation. Their durability ensures that the subfloor remains intact even under harsh environmental conditions, extending the lifespan of the trailer and reducing maintenance costs.