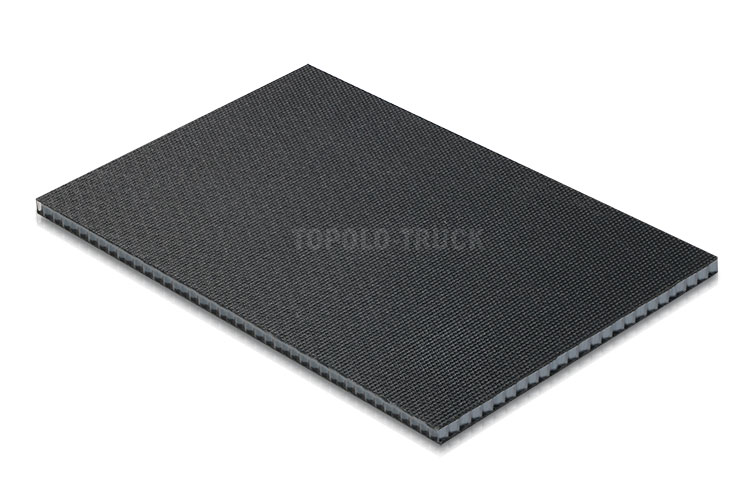

As a new type of truck floor material, anti-slip polypropylene honeycomb panels have excellent properties such as high strength, waterproof, lightweight, and wear resistance. They have replaced anti-slip aluminum panels on many vehicles. Especially in dry trucks and dump trucks, it has proven to be a reliable choice. Anti-skid polypropylene honeycomb panels are undoubtedly a representative material of lightweight, which combines lightness and strength, and is corrosion-resistant. Using it as a truck floor will bring you more economic benefits and safety performance, and it is a product that guarantees durability and safety.

DESCRIPTION

Product Features

- Wear-resistant and anti-skid.

- High strength-to-weight ratio.

- Impact-resistant.

- Chemical-resistant.

- Easy to install and maintain.

Specifications

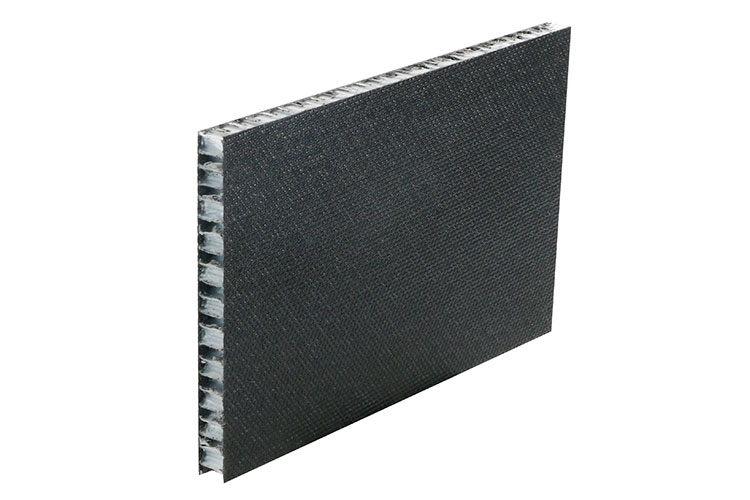

- Top Facing: Embossed CFRT (Continuous Fiber Reinforced Thermoplastic)

- Core Materials: PP (Polypropylene) honeycomb. (Density: 60~160kg/m³)

- Bottom Facing: Embossed CFRT (Continuous Fiber Reinforced Thermoplastic)

- Width: Max 2.8m.

- Length: Max 12m.

- Thickness: 5~120mm.

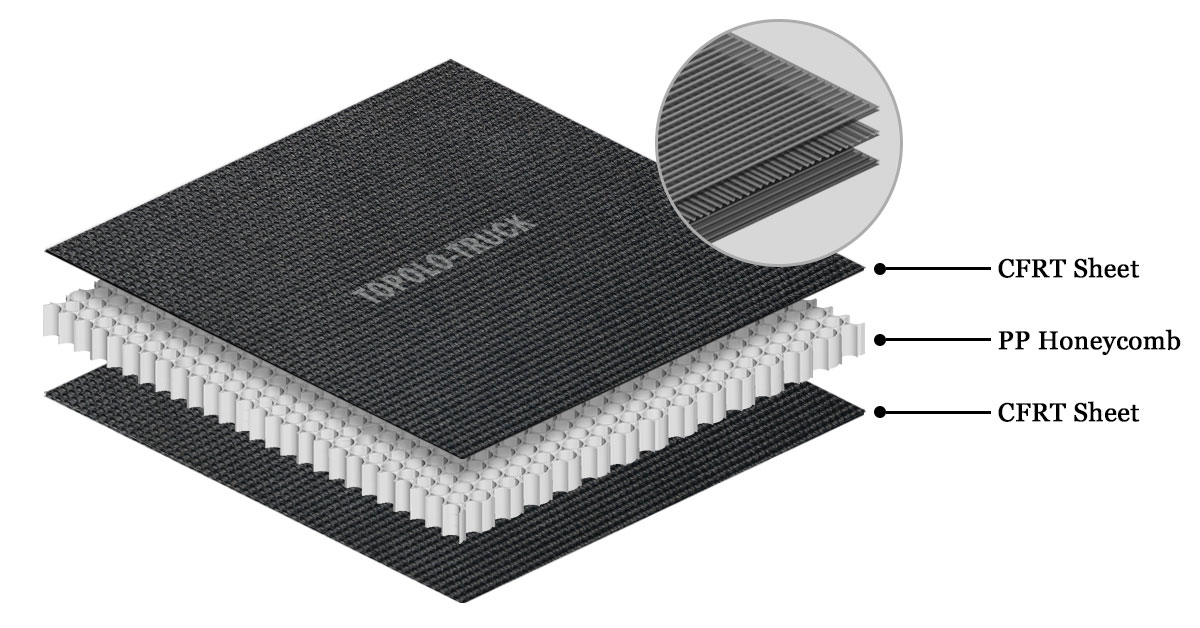

Structure of Anti-slip Polypropylene Honeycomb Panels

Details

CFRT Skin

The honeycomb panel has CFRT sheets as the upper and lower skins. CFRT sheets are made by laying multi-layer thermoplastic prepreg unidirectional tapes at preset angles. Due to the reinforcement of continuous glass fibers, CFRT sheets offer excellent rigidity and durability.

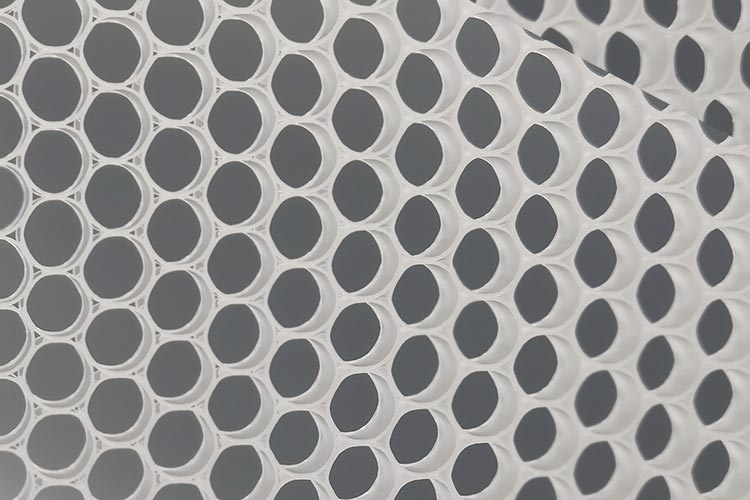

Polypropylene Honeycomb Core

The polypropylene honeycomb core is designed with a honeycomb structure, which optimizes the ratio of weight to strength. It provides excellent compressive and impact resistance while effectively reducing the weight of the panel.

Production technology of anti-slip polypropylene honeycomb panels

The anti-slip polypropylene honeycomb panel is produced using advanced thermoplastic lamination composite technology. This process combines thermoplastic prepreg unidirectional tapes and polypropylene in one step, completing the hot lamination, embossing, and cutting processes. The high-efficiency production method resolves potential issues with adhesive delamination or cracking that are common in traditional honeycomb boards, ensuring the stability and long-term reliability of the product.