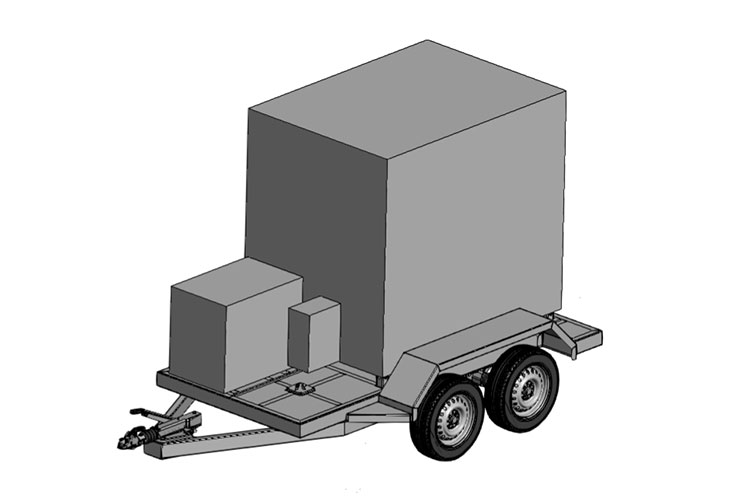

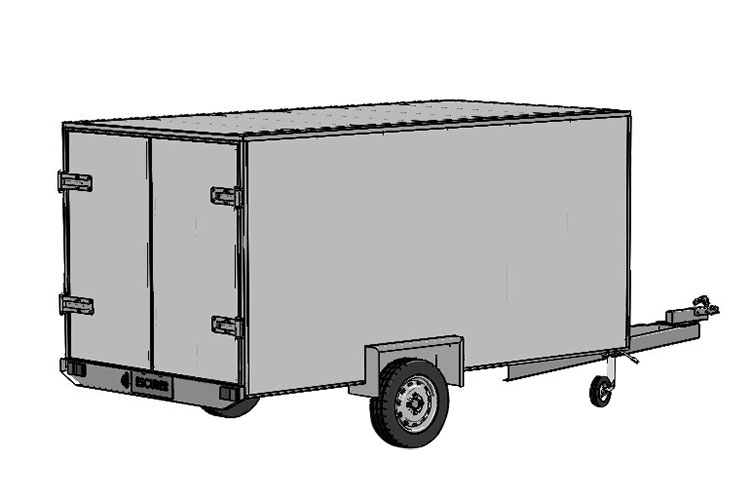

The mobile freezer trailer is a storage box with simple structure, flexible operation and lightweight, which is suitable for the rapid transfer of goods between short distances. These small refrigerated trailers are commonly found in areas such as catering, retail and pharmaceutical distribution, especially when transporting goods within cities. Although their carrying capacity is limited, they are a very practical and convenient choice for scenarios that require frequent short-distance transportation.

Features of Mobile Freezer Trailers

- Compact size

Mini refrigerated trailers are relatively small, making them ideal for getting in and out of tight areas, such as city streets or small cargo-handling stations. - Low-temperature maintenance

They are equipped with refrigeration or freezing facilities, which can keep the goods in a cold state during transportation, ensuring the quality and freshness of the goods. - Flexibility

Due to their small size, these trailers are more flexible for easy maneuvering in busy urban environments, while also allowing easy parking and storage. - Economical

Mini refrigerated trailers are more cost-effective for transporting small loads because they don’t use as much fuel as larger trucks. - Eco-friendly

Thanks to its smaller size, the mini refrigerated trailer can reduce carbon emissions and road congestion.

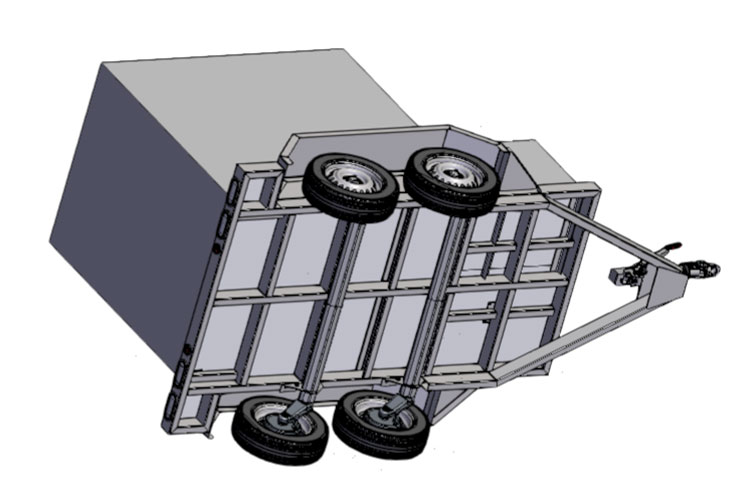

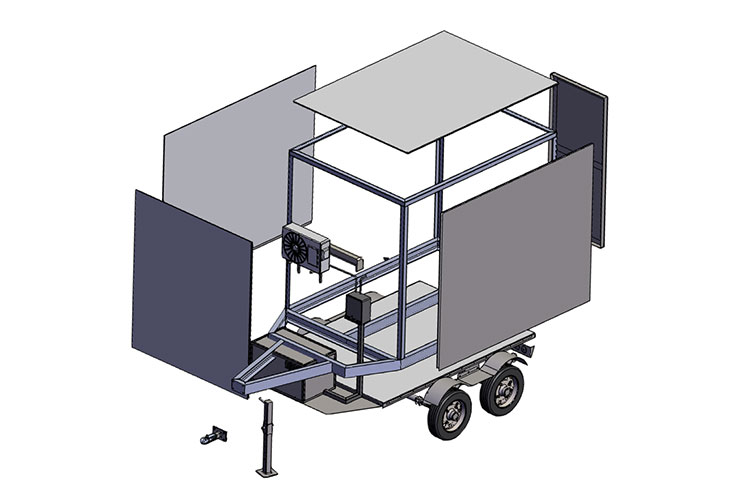

TOPOLO-TRUCK makes your trailer project more seamless

TOPOLO-TRUCK provides both single-axle and dual-axle mobile freezer trailers to meet diverse transportation needs. We offer both pre-assembled kits and fully assembled trailers, providing flexibility for customers to complete their trailer projects. By offering these three assembly options (CKD, SKD, and CBU), TOPOLO-TRUCK allows clients to select the assembly mode that best suits their operational needs and budget. Whether you need a fully assembled trailer or prefer to handle the assembly process locally, we provide the flexibility to support your project requirements.

Common Box Body Sizes

(For reference, the actual requirements should take precedence.)

| Model | Trailer Type | Box Length | Box Width | Box Height | Load Capacity |

|---|---|---|---|---|---|

| Compact Model | Single-Axle | 3m – 4m | 2.0m – 2.2m | 2.4m – 2.6m | 2,000kg – 3,000kg |

| Standard Model 1 | Single-Axle | 4m – 7m | 2.2m – 2.5m | 2.5m – 3m | 3,000kg – 5,000kg |

| Standard Model 2 | Dual-Axle | 7m – 10m | 2.4m – 2.6m | 2.6m – 3m | 5,000kg – 8,000kg |

| Extended Model | Dual-Axle | 10m – 12m | 2.4m – 2.6m | 2.6m – 3m | 8,000kg – 10,000kg |

| Heavy Duty Model | Dual-Axle | 8m – 10m | 2.5m – 2.8m | 2.7m – 3m | 10,000kg – 12,000kg |

Design Services

TOPOLO-TRUCK boasts a professional trailer design team. Simply provide the relevant parameters, and we will generate detailed 3D design drawings and offer optimized design solutions tailored to your specific needs. Our team is committed to ensuring that designs maximize functionality, efficiency, and performance, helping you achieve the best results for your trailer projects.

Box Material

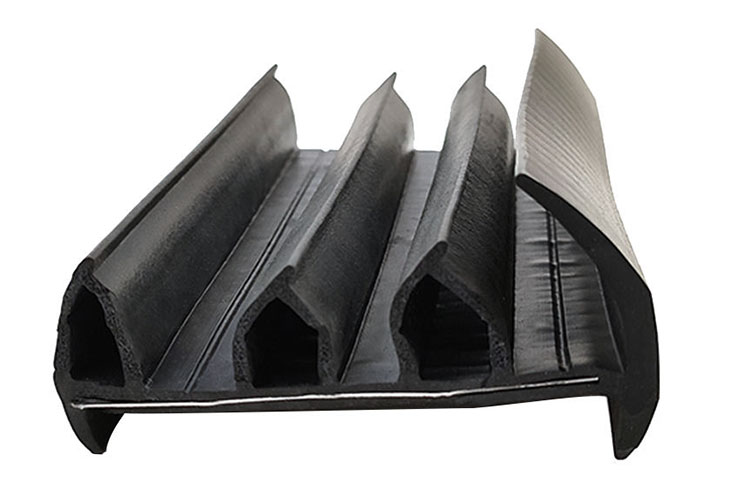

Insulation, sturdiness, sealing, and waterproofing

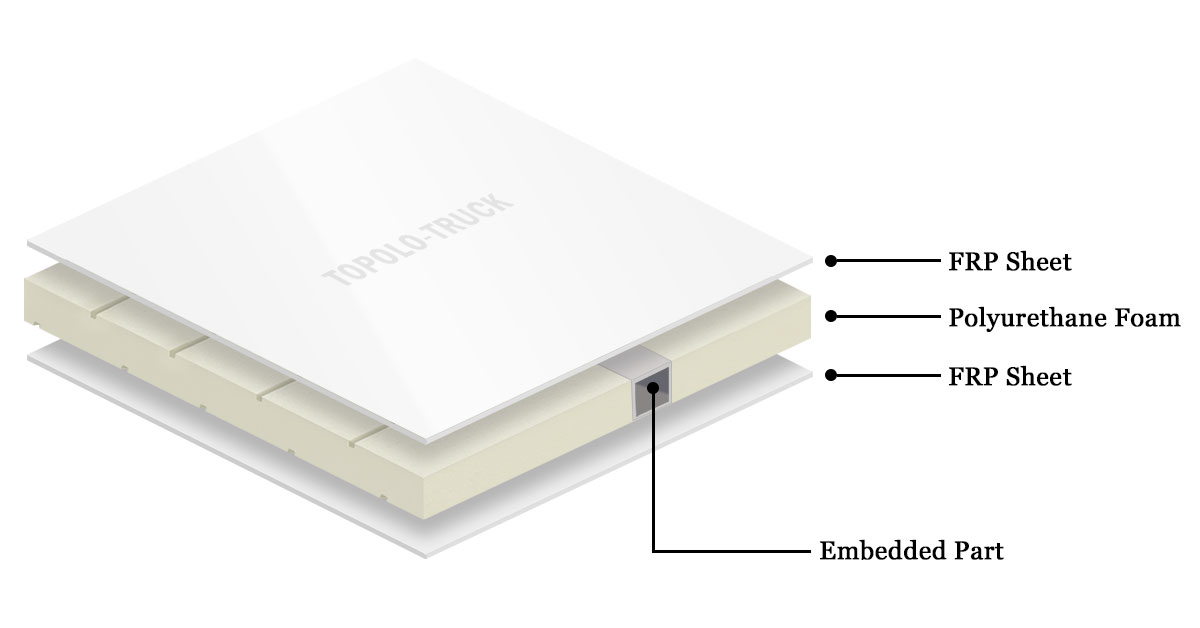

FRP Composite Panel

Core Insulation Guarantee

Utilizing a composite structure of food-grade antibacterial gelcoat FRP sheets and low thermal conductivity polyurethane, this design effectively blocks heat exchange at its source, providing insulation performance far exceeding industry standards.

Each side of the trailer box is a single, seamless panel, with a 100-120mm thickened design, significantly reducing heat loss and providing excellent structural stability.

Furthermore, FRP material itself is waterproof, corrosion-resistant, and easy to clean. Combined with food-grade antibacterial gelcoat, it effectively inhibits bacterial growth, fully meeting the hygiene requirements of the food and pharmaceutical industries, offering reliable waterproofing and insulation.

Custom Parts & Accessories

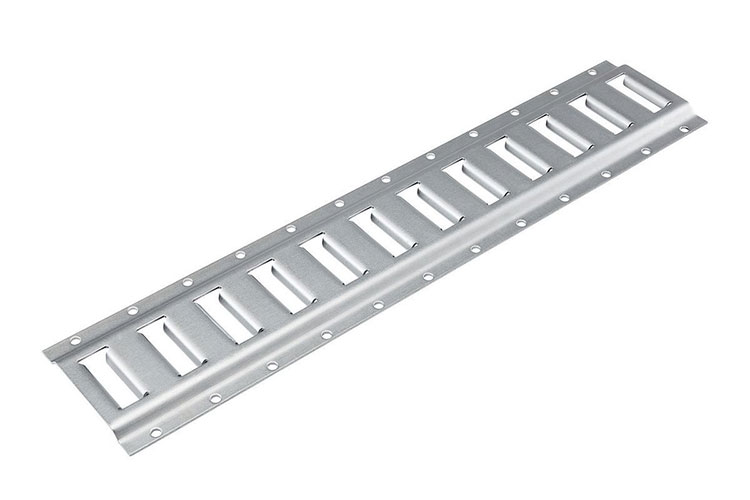

Flexible Flooring Options

We offer three types of customized flooring solutions to meet various transportation scenarios based on different cargo types, refrigeration requirements, and load-bearing needs。

Anti-slip Checkered Aluminum Plate

Lightweight, high-strength, with excellent anti-slip properties and easy to clean. Ideal for transporting general fresh produce, food, and similar goods.

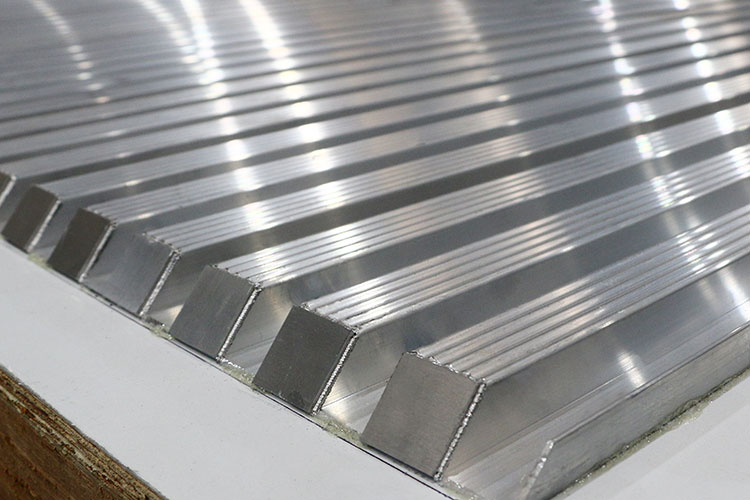

Aluminum Duct Flooring

Higher load-bearing capacity with good drainage. Suitable for heavy-duty cargo or scenarios requiring regular cleaning.

Quartz Sand Flooring

Higher slip resistance, wear-resistant, and corrosion-resistant. Perfect for transporting goods with stringent environmental requirements, such as pharmaceuticals and precision cold chain products.

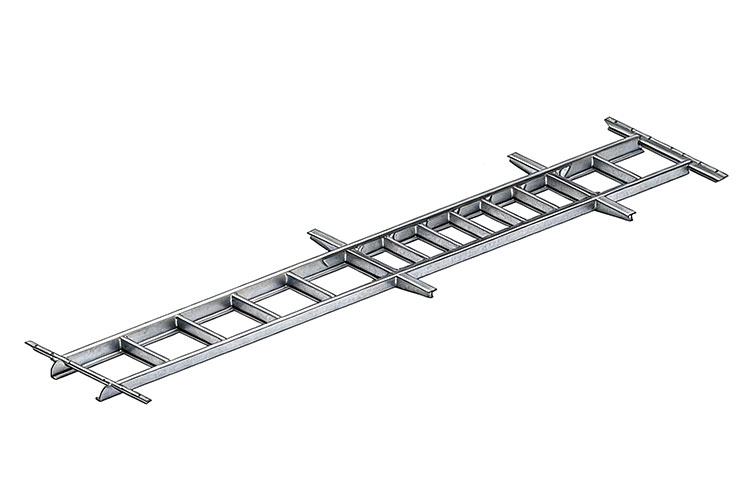

Chassis

A Stable and Durable Load-Bearing Foundation

The chassis structure is optimized through finite element analysis, with a well-planned layout that ensures even load distribution, effectively dispersing the weight of the cargo. The chassis frame is made from high-strength galvanized steel or painted steel, both of which undergo rigorous rust and corrosion protection treatments.

Galvanized Steel

The hot-dip galvanizing process forms a dense anti-rust layer, effectively resisting corrosion from rain, road salts, and other environmental factors, thus extending its service life.

Painted Steel

Multiple layers of spray painting provide both rust resistance and aesthetic appeal, offering a balance of durability and visual quality.

Refrigeration Equipment (Optional)

Customers have the option to purchase and install their own refrigeration units. Additionally, we offer Carrier, Thermo King, and other top brands of refrigeration units, and we provide full installation and commissioning services to ensure optimal performance.

For more information on customized solutions for mobile freezer trailers, please contact us.