We use lightweight, high-strength fiberglass facing PET foam sandwich panels to manufacture dry cargo boxes for trucks and trailers. A lighter box body means more fuel savings and longer vehicle driving distance. Using our PET foam sandwich panels, you can optimize your vehicle well. These panels are carefully built with maximum durability, and lightweight, and are ideal for maintaining high standards for all dry cargo transportation.

Specifications

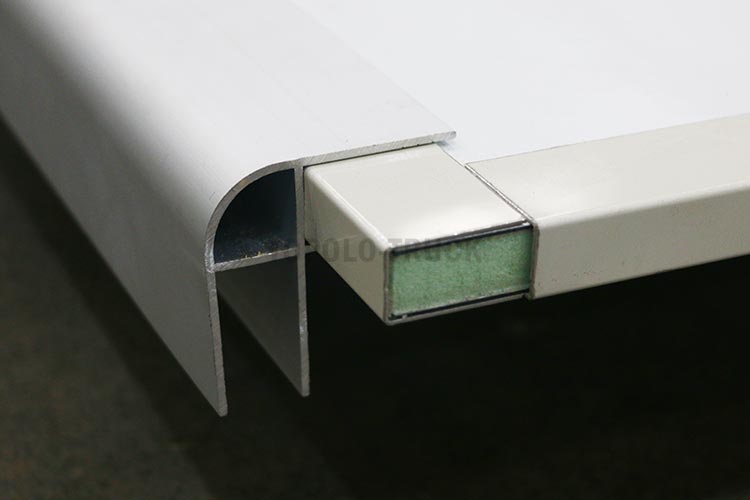

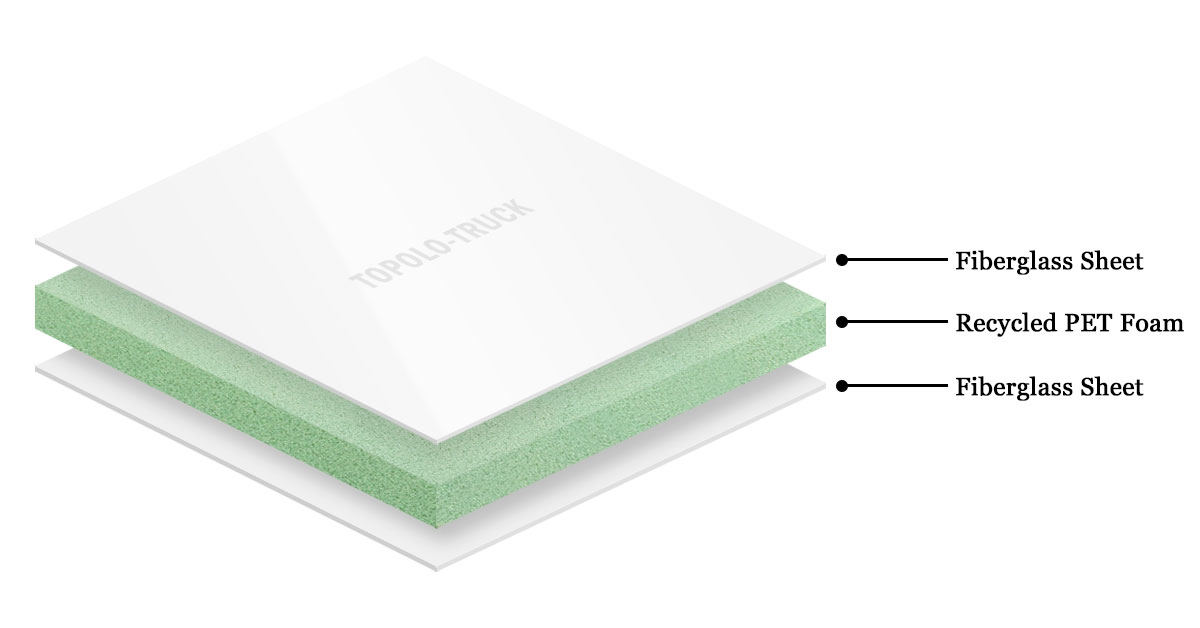

- Skin: FRP sheet or CFRT sheet. (Thickness: 0.7~2.0mm)

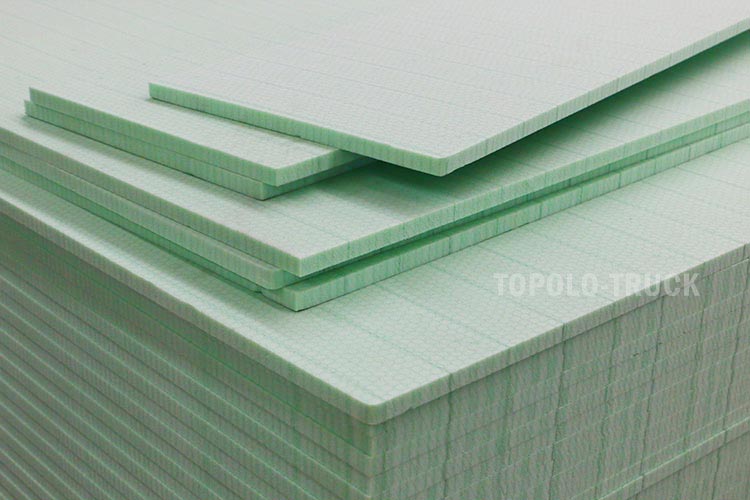

- Core Materials: Recycled PET (Polyethylene Terephthalate) foam. (Density: 60~300kg/m³)

- Width: Max 3.2m.

- Length: Max 12m.

- Thickness: 10~150mm.

DESCRIPTION

Structural Diagram

The environmental advantages of recycled PET foam.

Recycled PET foam is not only a material with excellent performance but also significantly reduces the environmental burden by promoting plastic recycling and resource circulation. It aligns with the concept of green and sustainable development, making it an ideal material for sustainability.

- Reduces Carbon Footprint

Lower Production Energy Consumption: The production process of recycled PET foam typically consumes less energy compared to producing new PET foam from virgin materials. This not only reduces production costs but also lowers greenhouse gas emissions, contributing to reducing the carbon footprint of businesses and supporting global climate change mitigation efforts.

- Conserves Water and Energy

Resource Conservation: The manufacturing process for recycled PET foam generally requires less water and energy compared to producing new PET foam from raw materials. This reduction in resource use helps decrease the environmental strain from both water and energy consumption.

- Reduces Landfill and Incineration

Less Waste Disposal Burden: By recycling PET bottles, packaging, and other waste, the need for landfilling or incinerating plastics is reduced. Landfilled plastics can pollute soil and water, while incineration releases harmful gases. The use of recycled PET foam helps mitigate both of these environmentally harmful waste disposal methods.

- Reduces Plastic Pollution

Addressing Plastic Pollution: PET is one of the most widely produced and consumed plastics worldwide. Recycling and repurposing it into foam material helps reduce the negative impact of single-use plastics on the environment. Plastic pollution is a severe issue affecting marine ecosystems, and using recycled PET foam helps decrease the amount of plastic entering water bodies.

- Non-Toxic and Harmless

Recycled PET foam is free from harmful chemicals (such as chlorine, benzene, etc.), making it safer for both human health and the ecological environment compared to some traditional plastic foam materials.

Expert in Box Body Composite Panels

TOPOLO-TRUCK has developed a series of high-quality composite panels for box truck and trailer bodies. Our composite panels are designed to perfectly combine strength, quality, aesthetics and environmental protection requirements, which can help you improve the durability, safety and transportation efficiency of your trucks. We use industry-leading materials and technologies to carefully build and provide the best solutions for your vehicle projects, and provide high-quality products that meet strict standards and exceed customer expectations.