Workshop trailers are highly customizable mobile work units that integrate transportation, on-site operation, equipment storage, and technical support. They are widely used in various industries and application scenarios.

- On-site Maintenance and Repair.

- Mobile Manufacturing Units

- Emergency service and rapid response.

- Specialized industry applications.

Trailer box dimensions (customizable)

- Length: 2.0m – 6.5m.

- Width: 1.2m – 2.4m.

- Height: 1.0m – 2.7m.

We deliver to you complete trailers or pre-assembled kits. (Excluding interior configuration)

DESCRIPTION

TOPOLO-TRUCK

The Expert in Designing and Building Solutions

Customized workshop trailers are highly integrated mobile working solutions. Through proper application planning, advanced composite body materials, and well-matched chassis system design, workshop trailers significantly improve operational efficiency, safety, and long-term value, meeting the diverse requirements of different industries.

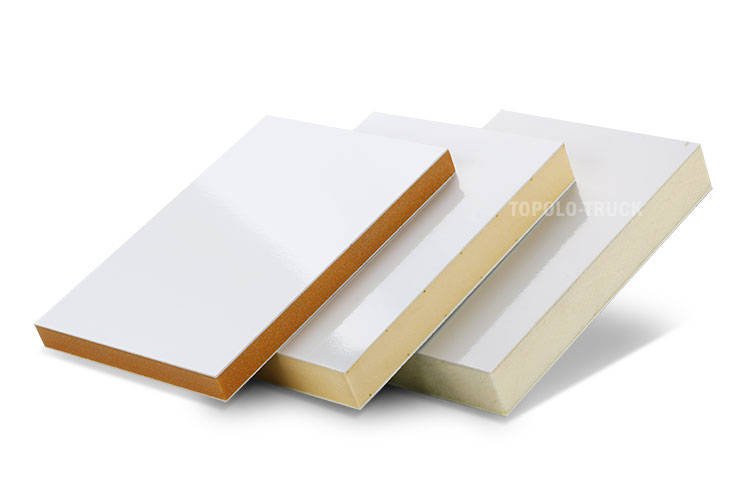

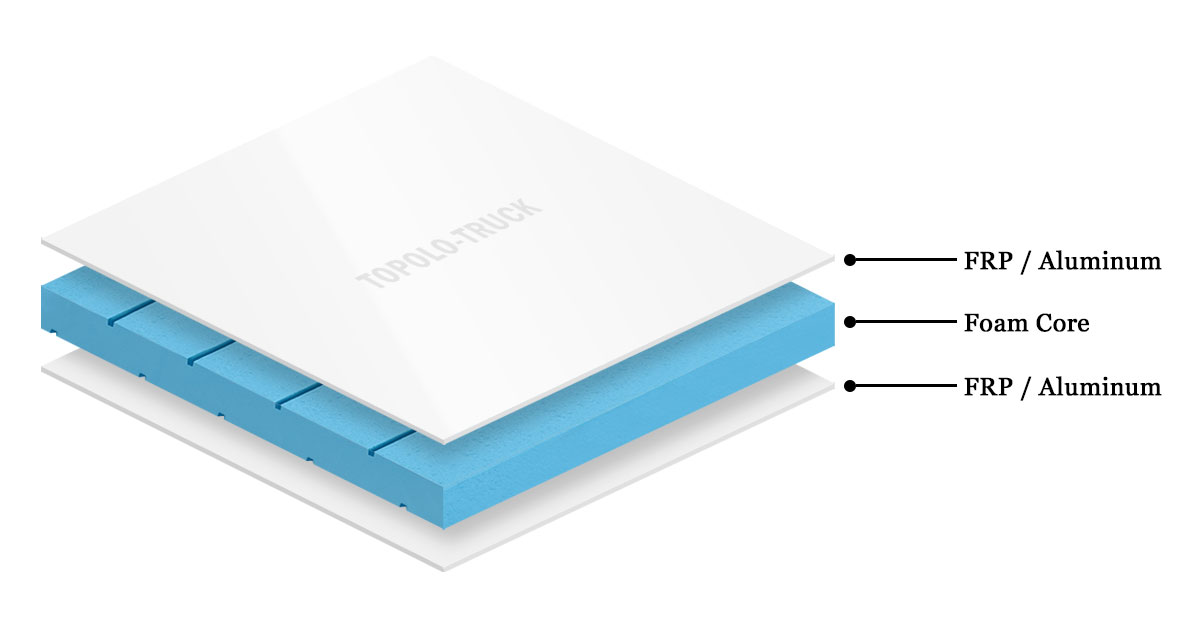

Body Materials

The body structure of a workshop trailer is typically built using insulated foam sandwich panels, which offer an optimal balance between lightweight design, structural strength, and durability. Different facing materials can be selected based on operating environment, performance requirements, and budget.

Advantages of Insulated Foam Sandwich Panels

☑ Excellent Thermal Insulation

Maintains a stable internal working environment and reduces external temperature and noise impact.

☑ High Strength-to-weight Ratio

Improves payload efficiency and reduces towing energy consumption.

☑ Excellent Sealing

One-piece bonded structure with superior sealing performance. Dustproof, waterproof, and resistant to condensation, suitable for all-weather operation.

FRP(GRP) Skin or Aluminum Skin

FRP (Fiberglass Reinforced Plastic) Skin

Outstanding corrosion resistance

Ideal for high-humidity, coastal, chemical, or mining environments.

High impact resistance and fatigue strength

Withstands vibration and structural stress caused by frequent transportation and rough road conditions.

Easy to clean with low maintenance cost

UV-resistant gelcoat surfaces ensure long-term appearance and performance.

Excellent electrical insulation properties

Especially suitable for electrical and telecommunications workshop trailers.

Aluminum Skin

Extreme lightweight construction

Significantly reduces overall trailer weight and increases available payload.

Professional industrial appearance

Clean metal finish suitable for branding and high-end applications.

Good weather resistance and recyclability

Supports environmental sustainability goals.

High structural rigidity

Well-suited for light- to medium-duty workshop trailers and long-distance transportation.

Chassis Configuration for Workshop Trailers

The chassis is the structural foundation of a workshop trailer and directly determines its load capacity, driving stability, and operational safety. Chassis specifications are customized based on gross weight, operating frequency, and road conditions.

Chassis Frame Materials

High-Strength Structural Steel (Q345 / S355, etc.)

High load capacity with controlled cost, ideal for heavy-duty applications.

Hot-Dip Galvanized Steel Frames

Enhanced corrosion resistance and extended service life.

Aluminum Alloy Chassis

Significant weight reduction for applications with strict lightweight requirements.

Axle Configuration

Single Axle

Suitable for lightweight workshop trailers with high maneuverability and small turning radius.

Tandem Axles

The most common configuration, offering higher load capacity and excellent driving stability.

Triple Axles or More

Designed for heavy-duty or specialized workshop trailers operating under high load conditions.