How to make the refrigerated truck have a better cooling effect, in addition to choosing a suitable refrigeration unit, the selection of the box material is also very important. Choosing the right box insulation material can not only provide a stable cooling environment but also reduce energy consumption. There are many thermal insulation materials currently on the market for truck boxes, the most popular of which are XPS and PU foam core composite panels.

Basic Specifications

- Insulation material: PU(Polyurethane) foam, XPS(Extruded Polystyrene) foam.

- Skin material: Flat FRP sheet.

- Other accessories: Aluminum profile extrusions.

- Total thickness: 50~150mm.

- Width: up to 3.2m.

- Length: up to 12m.

Features

- Thermal insulation.

- Waterproof and moisture-proof.

- Strong and durable.

- Weather resistant.

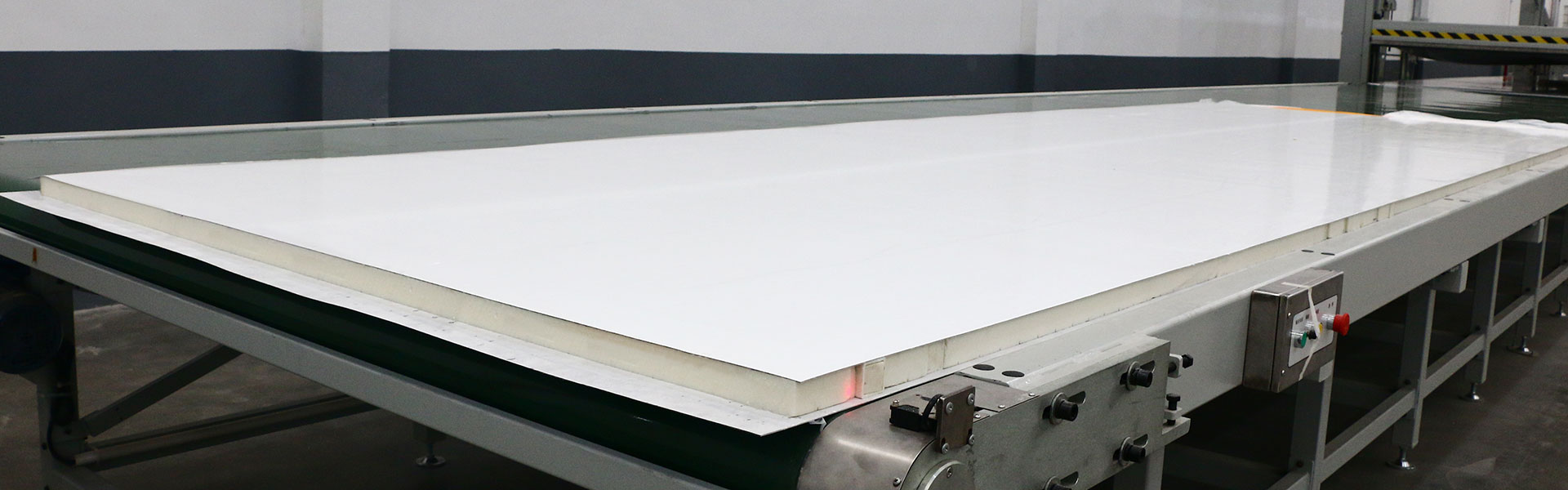

One-Piece Truck Insulation Box Panels

We process truck insulation panels using one-piece composite panel technology, where the skin and core are laminated together in a press before they are CNC machined. These insulation panels can be spliced together quickly, which greatly improves the efficiency of building the refrigerated truck box.

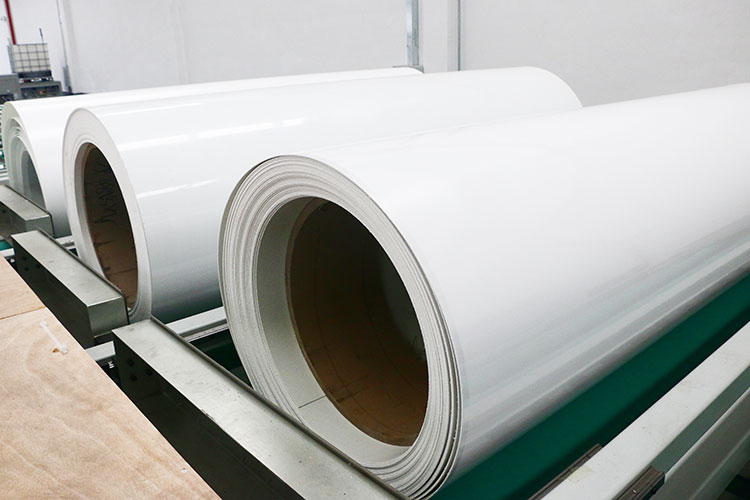

PU Foam Insulation Panels

PU sandwich panels are excellent in insulating heat conduction. PU foam not only has extreme thermal conductivity but is also relatively lightweight. The FRP skinned PU foam core sandwich panel is a one-piece extrusion composite panel, which is different from the traditional injection molding method.

XPS Foam Insulation Panels

In XPS insulation panels, the XPS foam layer is used as a thermal insulation material, which has excellent thermal insulation properties and can effectively reduce heat transfer. XPS foam is a closed-cell foam with low thermal conductivity and high resistance to water absorption, making it ideal for thermal insulation.

Our Quality Commitment

☑ Attractive Appearance

The surface of the insulation foam composite panel is smooth and flat, without protrusions, depressions, macular spots, black spots and other quality problems that affect the aesthetic effect.

☑ Strong Bonding

The skin and core material are tightly bonded together, eliminating the risk of delamination and maintaining long-term stability even under vibration, shock, and temperature changes. It will not deform under extreme temperatures ranging from -40°C to +80°C.

☑ Sturdy Structure

It effectively resists deformation, impact and fatigue during transportation and long-term use, ensuring reliable performance and structural stability even under harsh operating conditions.

Customized Services

We customize different solutions for the application requirements of refrigerated truck manufacturers.

Selection of FRP skin material

- In addition to choosing the traditional thermoplastic FRP, we have also developed a more cost-effective CFRT (Continuous Fiberglass Reinforced Thermoplastic).

Embedded reinforced material

- Some structural materials will be added inside the box panel to enhance the strength. You can choose different embedded materials such as FRP pipe, plywood, steel pipe, aluminum pipe, aluminum pipe, timbers, etc. It depends on the final application.

CNC processing service

- We will process the required shape on the CNC platform at one time according to the design drawings.

Other accessories

- We provide CKD refrigerated body service, in addition to box panels, we provide other accessories such as door locks, refrigeration units, hinges, sub-frames, sealing strips, aluminum profiles, various sheet metal parts, etc.