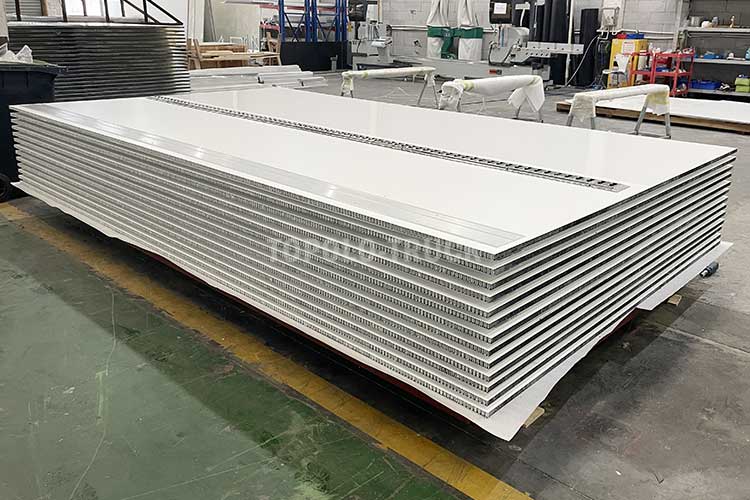

SKD (Semi Knocked Down)

The SKD (Semi Knocked Down) method involves partially disassembling the vehicle into major components, transporting them to the destination, and completing the final assembly locally. Compared with importing fully built units, the SKD model offers multiple advantages in terms of cost, efficiency, and flexibility.

- Reduced Transportation Costs

By separating major components, the overall volume is reduced, helping lower freight space requirements and shipping expenses.

- Lower Import Tariffs

Many countries impose high duties on fully built units (CBU), while SKD components are usually taxed at lower rates, significantly reducing total import costs.

- Higher Local Assembly Efficiency

Only partial assembly is required at the destination, with simpler processes and shorter assembly time. It is much easier to execute than the CKD model.

- Supports Local Manufacturing

SKD helps develop local assembly capabilities and meet regional regulations or policies regarding local production ratios.