In reefer trucks, the design of the door frame is very important as it needs to provide an effective seal to prevent cold or hot air from entering the interior of the truck, thereby ensuring that the cargo remains at the proper temperature. In addition, it is very important for stabilizing the structure of the reefer box, providing stable structural support for door panels and box panels.

DESCRIPTION

Basic specifications

| Size | 2.1*2.1m or customized |

| Material | 304 stainless steel plate |

| Sheet metal thickness | 2.2mm |

| Surface treatment | Polished |

Details and Features

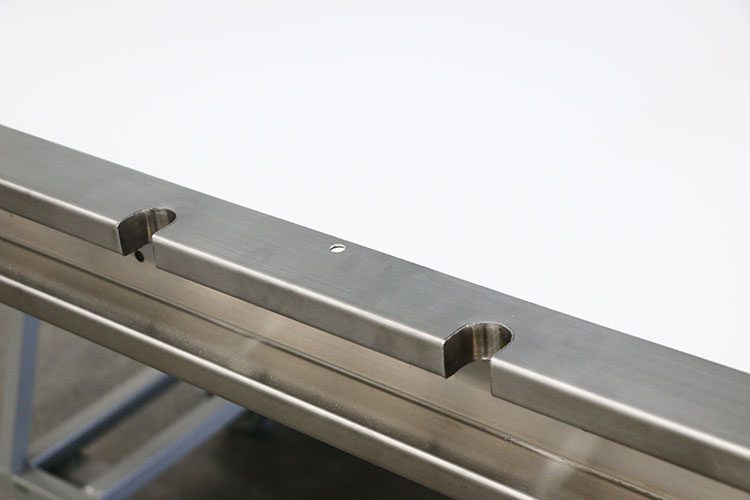

Stainless Steel Stamping Profiles

- The door frame material is made of food-grade 304 stainless steel with a thickness of 2.2mm. 304 stainless steel has high strength and excellent corrosion resistance, and the surface is smooth, easy to clean, and difficult to breed bacteria. Although aluminum door frames are corrosion-resistant, their hardness is much lower than stainless steel, and their structural strength is not as good as stainless steel door frames. Galvanized steel door frames have higher strength, but they are easily rusted and can damage the overall structure of the reefer truck box.

Hidden Rivet Design

- We abandoned the traditional rivet process and used flat-head screws to fix the door frame. The screws can be perfectly embedded into the door frame, and the surface of the screw joint is flat without any bulges. This design not only makes the reefer box look good but will not cause scratches to the goods.

Traceless Welding

- The welding of many reefer truck door frames on the market is very rough: the welding area is uneven and the welding is not strong enough, causing the welding to fall off. These problems not only make the door frame look ugly but also reduce the structural strength. We use traceless welding technology, the seams are smooth and the welding is firm. After the welding process is completed, it is polished and strength tested.

Safe Packaging

- In CKD, although the door frame is a relatively solid product, many manufacturers tend to ignore its packaging. For example, they do not use external flexible packaging and have no fixing devices, causing the door frame to be squeezed, deformed or scratched by other heavy objects during transportation. We adhere to strict packaging standards: use waterproof packaging film, use packaging foam on the corners, use fumigated wooden frames for fixation, etc.