TOPOLO-TRUCK not only provide scientifically designed reefer truck box floors, but also provide pre-assembly services, saving customers a lot of assembly time.

The floor of the reefer truck needs to ensure the most basic thermal insulation function, and the surface floor uses different shapes and designs according to the purpose of the goods being transported. Installing the correct floor type will greatly improve the efficiency of the reefer truck box, reduce power consumption, and facilitate maintenance.

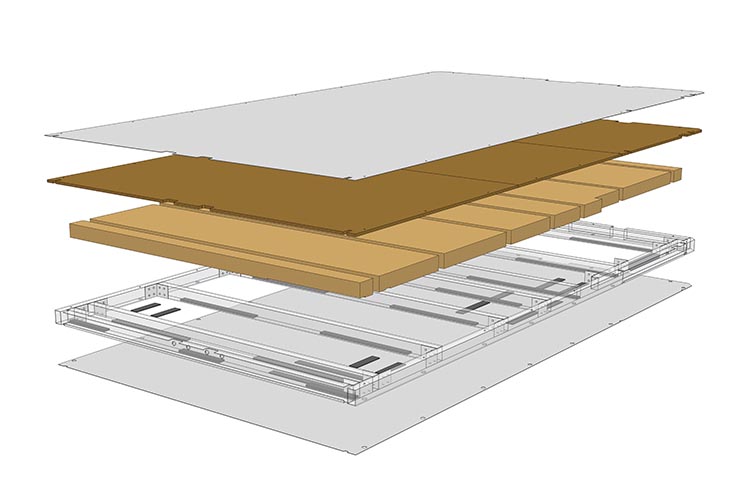

Subflooring

The subfloor of a refrigerated box adopts a multi-layer composite structure, consisting of a waterproof reinforced skin, thermal insulation foam core, load-bearing layer, and structural framework. This design ensures high load capacity while delivering excellent thermal insulation and long-term durability.

Waterproof Reinforced Skin (FRP Sheet)

The floor surface uses high-strength FRP (Fiberglass Reinforced Plastic) sheets as the waterproof skin, offering outstanding water resistance, corrosion resistance, and chemical stability. The dense, smooth surface is easy to clean and disinfect, effectively inhibiting bacterial growth and fully meeting the stringent hygiene requirements of cold-chain transportation.

Insulation Core Material (XPS or PU Foam)

The insulation layer is made of extruded polystyrene (XPS) foam or rigid polyurethane (PU) foam, both featuring a very low thermal conductivity. This significantly reduces heat transfer between the interior and exterior of the box, improves overall insulation efficiency, lowers refrigeration energy consumption, and ensures stable internal temperatures.

Plywood Load-Bearing Layer

A high-strength, waterproof plywood layer is incorporated to enhance the overall rigidity and load-bearing capacity of the floor. It is designed to withstand concentrated loads from forklifts, pallets, and roll cages during frequent loading and unloading operations, minimizing long-term deformation and fatigue.

Non-Metal Structural Framework

The bottom structural framework is manufactured from non-metallic composite materials, eliminating thermal bridging and corrosion issues commonly associated with metal frames. This design provides excellent structural strength and dimensional stability while further improving insulation performance and service life.

Surface Flooring

The selection of the surface floor for a refrigerated box (refrigerated truck body or container) is critical because it directly affects hygiene, durability, thermal performance, and operational efficiency.

Rectangular Duct Aluminum Flooring

The floor with a rectangular cross-section doubles the floor area, allowing the cold air from above the reefer truck box to circulate and maintain a balanced temperature in each section of the box. And the sewage can be discharged quickly, which facilitates cleaning.

T-Shape Duct Aluminum Flooring

The T-shaped trough floor can improve air circulation efficiency to a greater extent and is usually used in large reefer trucks. Its disadvantage is that the T-shaped structure makes cleaning inconvenient.

Checked Aluminum Flooring

Anti-slip diamond floor is a commonly used reefer truck floor. It is generally used on small and medium-sized reefer trucks or reefer trucks with low refrigeration requirements. This is an economical and affordable choice.

Quartz Sand Flooring

Quartz sand flooring combines safety, durability, hygiene, and low-temperature stability, making it especially suitable for high-frequency loading and unloading and heavy-duty cold chain transportation.

Ribbed Aluminum Flooring

The surface has longitudinal reinforcing ribs to improve slip resistance and load-bearing capacity.