PVC Foam Sandwich Panels for Trailer & Truck Bodies

PVC(Polyvinyl Chloride) foam core composite panels are a new type of truck and trailer body material, primarily used for constructing high-performance cargo boxes or camper bodies.

PVC Foam – Balanced Performance

PVC foam is a rigid closed-cell foam material. Compared to other foams (PET, EPP, EPS, XPS, etc.), it has many advantages such as high strength, light weight, corrosion resistance, high temperature resistance, and water resistance.

Specification of PVC Foam Sandwich Panels

| Composition | Skin | FRP/GRP: Glass fiber reinforced plastics. |

| CFRT: Continuous fiber reinforced thermoplastic . | ||

| Aluminum Alloy. | ||

| Coated Steel. (GI, GL, PPGI, PPGL) | ||

| PVC Foam Core | Thermal Conductivity: 0.030-0.040 W/(m·K) | |

| Water Absorption: 0.2-1.0%. | ||

| Flame Retardant Grade: B1-B2. | ||

| Operating Temperature Range: -50°C to +80°C. | ||

| Density:60-250kg/m³. | ||

| Tensile Strength(a):1.8-9.2Mpa. | ||

| Tensile Modulus:75-320Mpa. | ||

| Compressive Strength:0.9-6.2Mpa | ||

| Compressive Modulus: 72-300Mpa | ||

| Shear Strength:0.76-4.5Mpa | ||

| Shear MPdulus:20-104Mpa | ||

| Shear Strain:20-40% | ||

| Panel width | ≤3.2m. | |

| Panel length | ≤12m. | |

| Panel thickness | 10~150mm. | |

| Composite methods | Adhesive bonding.(Unsaturated polyester adhesive, polyurethane adhesive, etc) | |

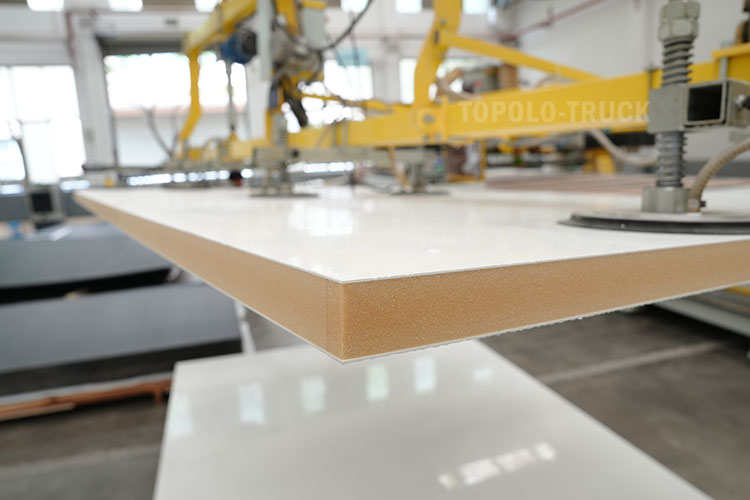

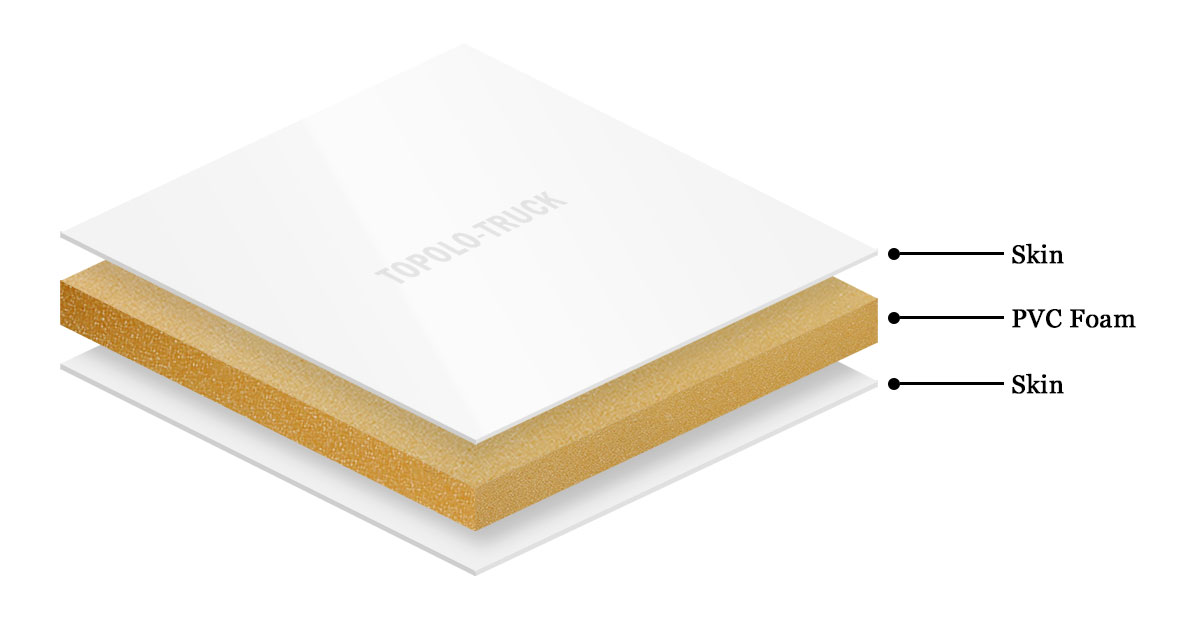

Structure of PVC Foam Core Sandwich Panels

Standard Structure

A typical skin-core-skin sandwich structure is simple in design, easy to process, and suitable for most cargo boxes or camper vehicle bodies.

Reinforced Structure

Structural strength is improved by adding energy-absorbing felt layers and internal embedded parts. Suitable for vehicle bodies requiring high structural strength.

Skin Materials

FRP/GRP Sheets

FRP sheets are an ideal material for truck and trailer bodies due to their lightweight, high strength, corrosion resistance, good thermal insulation, and weather resistance, making them widely used in various transportation vehicles such as refrigerated trucks and dry cargo trucks. They not only effectively reduce vehicle weight and improve transportation efficiency, but also possess UV resistance, impact resistance, and low maintenance costs, ensuring long-term vehicle stability in harsh environments. Furthermore, the excellent mechanical properties and aesthetically pleasing design of FRP sheets make them an essential component of various commercial vehicles.

CFRT Sheets

CFRT sheets, as a new type of thermoplastic FRP material, offer highly reliable vehicle body solutions thanks to their advantages such as high strength, lightweight, high temperature resistance, impact resistance, and corrosion resistance. Whether for refrigerated trucks, dry cargo trucks, or special-purpose vehicles, CFRT sheets can improve vehicle safety, durability, and transportation efficiency, while reducing maintenance costs and extending vehicle lifespan.

Aluminum Alloy Sheets

Using aluminum alloy sheets for truck and trailer bodies provides numerous advantages, including a lightweight structure, high strength-to-weight ratio, corrosion resistance, and low maintenance. These benefits lead to improved fuel efficiency, increased payload capacity, and lower operational costs. Additionally, aluminum’s recyclability and ability to withstand extreme conditions make it an environmentally friendly and durable option for commercial vehicle manufacturers.

Coated Steel Sheets

Coated steel sheets offer a highly durable, cost-effective, and versatile body solution. They combine high strength, corrosion resistance, and aesthetic appeal, while providing long-term protection against environmental and mechanical stresses.

Our Customized Solutions

TOPOLO-TRUCK’s customized composite panel solutions help your vehicle projects achieve more efficient, safe, and flexible local production, enhancing overall operational efficiency. Customize prefabricated composite panel kits for your vehicle projects to enable localized, fast assembly.

Optimized Panel Structure

Depending on the specific needs of the vehicle, we use various composite materials to provide higher strength, durability, and lightweight designs. Whether it’s FRP, aluminum alloy, or other composite materials, we tailor the panels to ensure maximum performance and reliability.

High-Precision CNC Processing

Utilizing high-precision CNC machining, we ensure that every panel meets strict size and tolerance requirements.

Obtain PVC Foam Sandwich Panel Samples

We offer customized PVC foam sandwich panel samples based on your provided materials or specific requirements for testing purposes.