Isothermal Truck Bodies

Home >> Truck Bodies

Unlike refrigerated boxes, isothermal boxes are designed to maintain a stable internal temperature throughout the journey, usually within the range of 5°C to 25°C. However, they are unable to maintain very high or very low temperatures for extended periods. They rely entirely on insulation materials to reduce heat exchange between the box body and the external environment. This insulation design allows isothermal boxes to slow down temperature fluctuations over a certain period, making them suitable for goods that do not require strict temperature control, such as dry goods, electronics, or pharmaceuticals.

Customized Isothermal Boxes for Trucks and Trailers

- Box Body Design

- Box Body Composite Panels

- Providing Accessories and Parts

- SKD, CKD, CBU Assembly Options

Size Specifications (Customizable)

| Type | Length (mm) | Width (mm) | Height (mm) |

| Mini | 2500 | 1770 | 1400 |

| Small | 2900 | 1800 | 1980 |

| 3200 | 2032 | 1613 | |

| Small/medium | 3410 | 2000 | 1910 |

| Standard light-duty | 4200 | 2050 | 2170 |

| Medium | 4200 | 2200 | 2300 |

| 4250 | 2050 | 1910 | |

| 4460 | 2170 | 2200 | |

| 4460 | 2170 | 2200 | |

| 4500 | 2100 | 2100 | |

| 4500 | 2200 | 2521 | |

| Medium/large | 5000 | 2300 | 2350 |

| 5100 | 2450 | 2335 | |

| 5803 | 2390 | 2469 | |

| Large | 6720 | 2350 | 2300 |

| 7000 | 2310 | 2300 | |

| Heavy-duty | 7920 | 2600 | 2600 |

| 8650 | 2585 | 2565 | |

| 8665 | 2600 | 2350 | |

| 8700 | 2480 | 2400 | |

| 9600 | 2600 | 2600 |

TOPOLO-TRUCK

The Trustworthy Expert in Building Truck and Trailer Bodies

TOPOLO-TRUCK is a unique technology solution company. We have a strong technical R&D team, advanced production factory and efficient service teams, which together build a solid foundation for development. As experts in box truck and trailer bodies, we provide design, material, manufacturing and packaging solutions.

All Sizes Can Be Customized

TOPOLO-TRUCK’s production facilities can meet the needs of various vehicle body manufacturing. We can customize light, medium, and heavy-duty trucks or truck bodies, ranging in size from small bodies less than 1 meter long to large bodies up to 12 meters long. Whether for intra-city delivery or long-distance logistics transportation, we can meet the needs of various industries for truck bodies.

Fast Assembly, High Efficiency Production

We are committed to simplifying the box body assembly process. All CKD kits are manufactured on our high-precision production line and assembled and inspected by experienced engineers. After the kits are shipped to their destination in containers, operators can quickly complete the assembly by following our provided installation instructions. The entire installation process requires no complex tools, only basic lifting equipment and tools such as electric drills, hammers, and wrenches. Even inexperienced operators can complete the assembly task, while skilled operators can achieve a high productivity of one person per day for one truckload.

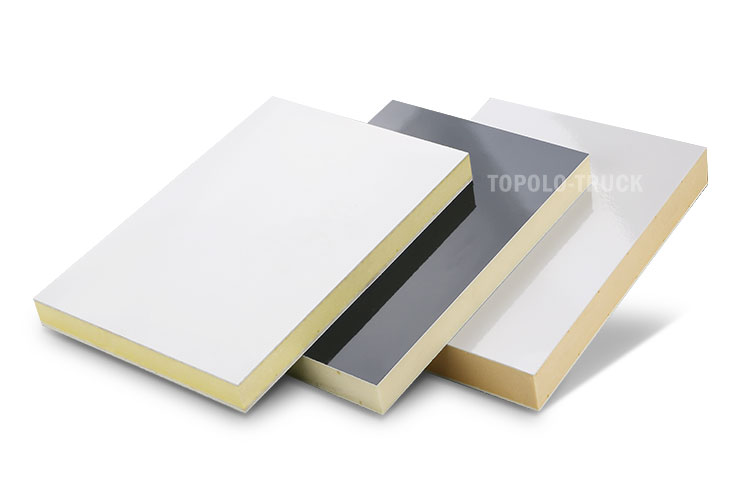

High-quality Thermal Insulation Materials

FRP skin foam sandwich panels are one of the most ideal insulation materials. These foams (such as extruded polystyrene (XPS) or polyurethane (PU) foam) provide extremely low thermal conductivity. By minimizing the impact of external temperature fluctuations, they effectively slow down the rate of temperature change inside the box body, ensuring that the cargo remains within a safe temperature range during transit. This insulation effect allows isothermal boxes to better maintain the temperature stability of goods, preventing external environmental changes from affecting the quality of the cargo.

XPS Insulation Panels

Advanced Production Technology

- The insulation materials we use are CE certified and meet the environmental protection standards of countries and regions such as Europe, North America, and Australia.

- Using vacuum lamination technology, the skin and the insulation core material are composited under high pressure in a vacuum state.

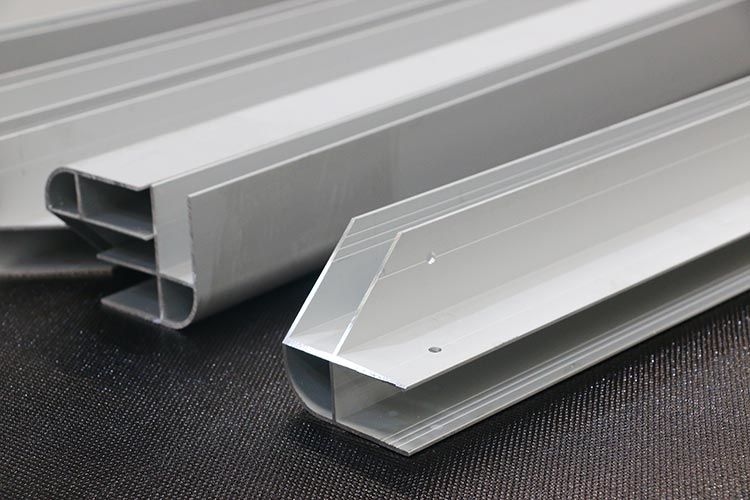

- Lightweight and waterproof reinforcement materials are embedded inside the insulation material to enhance its structural strength.

Customized Accessories and Parts

We design and manufacture various parts and accessories according to customer needs. Here are some common customized refrigerated truck body parts, such as refrigeration unit, inner partition, rear door, side door, corner cap, edging profile, door lock system, floor, E-track, suspension system, subframe, safety light, bumper, side guard, rear door lift platform, etc.

Flexible Assembly Method Selection

We offer complete or semi-assembled box body kits to ensure that all components are efficiently and precisely integrated, resulting in a high-quality finished product. These kits are designed to streamline the assembly process, allowing for faster, more cost-effective production while maintaining consistent quality. By providing pre-assembled or partially assembled parts, we reduce the time and complexity involved in manufacturing, ensuring that the final product meets the highest standards of durability, insulation performance, and overall functionality. Whether fully assembled or in kit form, our products offer flexibility and convenience to suit different customer needs.

Providing the Most Professional Solutions

- 20 years of experience in quantitative truck design and development.

- More than 100 manufacturing team.

- More than 10 international language service teams (English, Russian, French, Spanish, Portuguese, Arabic, German, Italian, Japanese, Korean).

- Cooperating with customers in more than 50 countries and regions.