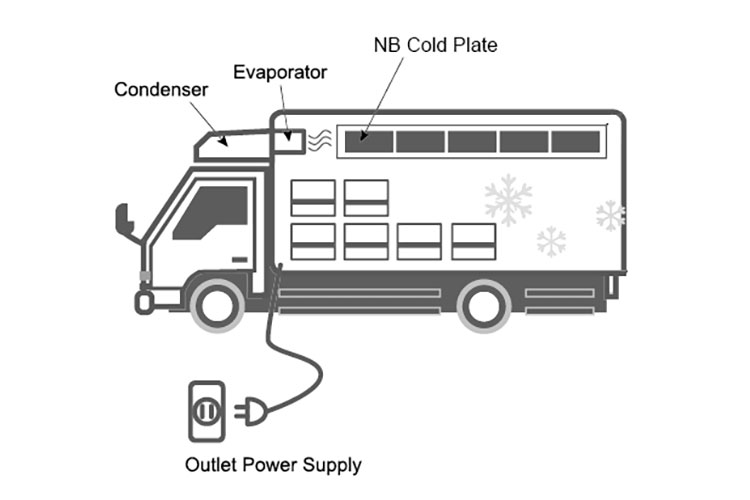

The main task of an ice cream delivery truck is to ensure that ice cream remains frozen during transport, even in hot weather, to prevent melting. Therefore, optimizing the refrigerated box of the ice cream truck is crucial, not only for the quality of the ice cream but also for improving transport efficiency and the durability of the truck body. The ice cream truck body has multiple side doors (2-5 on each side). It can be mounted on a truck chassis of 4.2 meters or longer. After the engine is turned off at night, the body can be charged via an external power outlet, and cooling plates can store cold energy and maintain a low temperature during daytime power outages for ice cream delivery.

We provide solutions for building ice cream truck bodies

As a professional truck body manufacturer, TOPOLO-TRUCK provides refrigeration box solutions for the food transportation industry. We offer both CKD kits and complete truck bodies, designed and customized to meet the customer’s size specifications, configuration requirements, and chassis parameters.

Easy and Quick Assembly

Thanks to its modular design, the ice cream truck body kit can be assembled efficiently without the need for complex tools. This streamlined assembly process significantly reduces setup time and minimizes the need for specialized equipment or extensive technical expertise. The modular parts are precisely pre-fabricated and pre-tested, allowing for quick and hassle-free assembly, ensuring that the truck body is ready for operation in a fraction of the time compared to traditional methods. This efficient assembly process not only saves labor costs but also enhances flexibility, making it easier to customize or modify the truck body according to specific needs.

Size Specifications (Reference)

| Side Door Configuration | Length | Width | Height | Compatible Chassis |

| 2 Doors | 4.2m – 7.0m | 2.2m – 2.5m | 2.5m – 3.0m | Suitable for 4.2m and longer chassis |

| 3 Doors | 4.2m – 7.5m | 2.3m – 2.6m | 2.6m – 3.2m | Suitable for 4.2m and longer chassis |

| 4 Doors | 5.0m – 8.0m | 2.5m – 2.8m | 2.7m – 3.3m | Suitable for 4.2m and longer chassis |

| 5 Doors | 5.5m – 9.0m | 2.6m – 3.0m | 2.8m – 3.5m | Suitable for larger chassis (8.0m and above) |

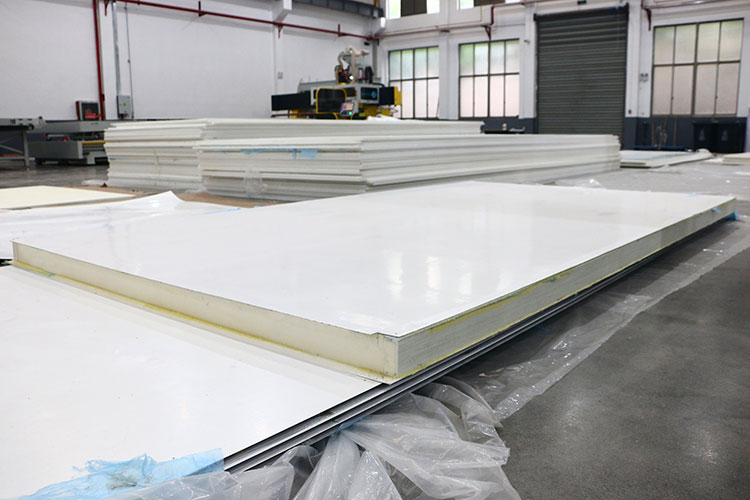

Box Body Panel Materials

Excellent insulation and sealing performance – The ice cream truck body panels are made of FRP skin and polyurethane sandwich core.

- Antibacterial GRP sheet as inner and outer skin: The surface is very smooth, resistant to fading, UV radiation, and easy to clean.

- Closed-cell polyurethane foam as insulation core: Excellent thermal insulation properties.

- Patented panel edge sealing technology: Prevents moisture from penetrating into the panel interior.

- Non-metal embedded parts: Blocks heat transfer, solving the thermal bridge problem.

- High-strength structural adhesive bonding for all panels: Ensures the most reliable connection, achieving a fully sealed structure for the vehicle body.

Parts Processing Technology

Door Seal

The door panels are equipped with high-elasticity EPDM rubber seals. This material provides excellent airtightness, ensuring that the door forms a perfect seal to prevent air leakage, which enhances insulation and security.

Edge Trim Profiles

The edging profiles use high-strength aluminum alloy extrusions, which not only firmly connect the body panels, enhancing the overall structural stability and durability, but also add aesthetic appeal with their refined design.

Flooring

The floor uses anti-slip aluminum sheets or ventilated aluminum slotted plates. This design provides a tough and wear-resistant surface while ensuring that the floor is easy to clean, which is crucial for maintaining hygiene and operational efficiency.

Interior Protection Railings

Protective railings are installed within the vehicle for safety purposes, reducing the risk of accidents during loading or unloading. These railings are accompanied by integrated lighting systems to ensure visibility and security in dark or low-light environments.

Locks, Door Frames, and Hinges

Manufactured from high-strength, polished 304/316 stainless steel, these components are corrosion-resistant and highly durable, ensuring long-term performance under extreme weather conditions.

Customizable Subframe

The subframe, made of either full aluminum or steel, is customizable to fit different chassis sizes. This flexibility allows for the creation of tailored solutions while maintaining structural strength and integrity, ensuring that the subframe aligns perfectly with the specific vehicle specifications.

Refrigeration Systems

Customers can specify the brand of the refrigeration unit or opt for one provided by us. We collaborate with well-known refrigeration unit brands, such as Thermo King, Carrier, and others, to offer reliable and high-performance solutions tailored to the customer’s needs. There are two main types of refrigerated truck refrigeration systems used for transporting ice cream, each designed to meet different temperature requirements and operating environments.

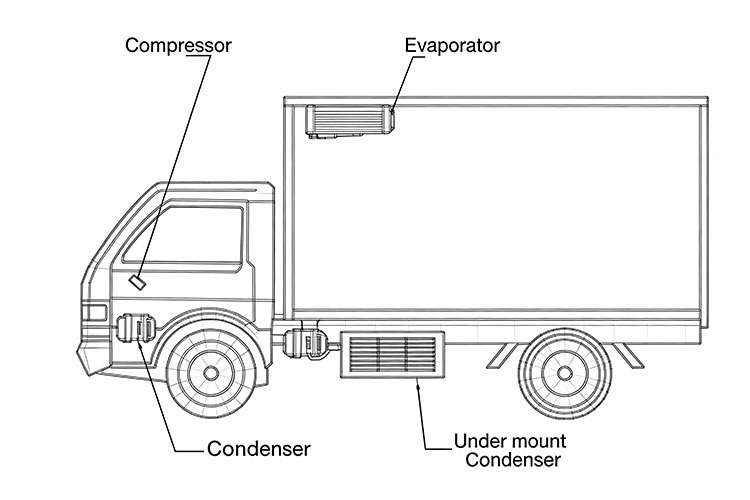

Independent Refrigeration Unit System

This type of system operates with its own independent power source and compressor. It is capable of maintaining compartment temperatures at –18°C, which is sufficient for ice cream transportation in most regions around the world. Independent units offer stable cooling performance, ease of maintenance, and wide compatibility with commonly used refrigerated truck models. Because they meet standard cold-chain requirements, they are the most widely adopted option in the industry.

Cold Plate Refrigeration System

Cold plate systems are more advanced and designed to achieve much lower temperatures, typically down to –30°C. This makes them particularly suitable for Gulf countries, tropical regions, and other environments with extremely high ambient temperatures where enhanced refrigeration performance is necessary.

Ice Cream Transport Operation Guidelines

To ensure effective temperature control throughout the transport process, the following operational guidelines must be followed:

01. Pre-cooling before loading

Always pre-cool the vehicle before loading. Ensure that the interior temperature reaches the required storage temperature for ice cream before beginning the loading process.

02. Control loading height

The stacking height of the goods should not exceed the level of the air vents to prevent blocking the airflow and affecting the circulation of cold air.

03. Use double-sided pallets

Use double-sided pallets for loading ice cream packaging. This ensures that cold air circulates freely across the floor of the truck, improving even cooling throughout the vehicle.

04. Avoid blocking the evaporator outlet

It is strictly prohibited to stack goods in front of the evaporator outlet. Doing so may obstruct the flow of cold air and cause localized temperature increases, compromising the cooling efficiency.