FRP Plywood Panels for Trailer & Truck Bodies

When selecting dry freight cargo body panel materials, FRP plywood sandwich panels are a cost-effective composite material. Compared with box panels with foam core or honeycomb core, FRP plywood is characterized by durability, easy cutting, high nail holding power, and easy assembly. After the seams are waterproofed, it can guarantee a long service life.

Features

- FRP plywood panels will not be brittle at ultra-low temperatures, will not deform at high temperatures, and can effectively prevent heat transfer.

- It can replace color steel sheets, aluminum sheets, stainless steel sheets, etc., and overcomes the shortcomings of traditional metal products such as easy to rust, easy to conduct heat, easy to dent and deform, difficult to clean, and easy to wear.

- The surface of FRP has been specially treated, which has the characteristics of high self-cleaning, anti-ultraviolet and anti-static properties.

Marine Plywood — Waterproof & Fire Retardant

The biggest disadvantage of plywood is its tendency to rot, deform, and degrade, especially in damp and high-humidity environments, which results in poor durability. To address this issue, marine plywood has been developed as a high-quality plywood specifically designed for wet, high-humidity, and other harsh environments.

It is made from premium hardwoods as the base material, and its structure is tightly pressed in layers to ensure high strength. Waterproof adhesives are used between the layers of wood, which have excellent water resistance and corrosion resistance. Even when exposed to water and moisture for long periods, the plywood remains intact without delaminating or peeling. Additionally, modern technology has integrated fire-retardant properties into this plywood to enhance its suitability for different environments.

By applying this durable marine plywood to truck and trailer bodies, it significantly improves the durability and stability of the vehicles.

Specification of FRP Plywood Panels

| Composition | Skin | FRP/GRP: Glass fiber reinforced plastics. |

| CFRT: Continuous fiber reinforced thermoplastic . | ||

| Plywood | Poplar, beech, birch, oak, pine, etc. | |

| Panel width | ≤ 3.2m. | |

| Panel length | ≤ 13m. | |

| Panel thickness | 5.0 – 50mm. | |

| Composite methods | Adhesive bonding.(Unsaturated polyester adhesive, polyurethane adhesive, etc) | |

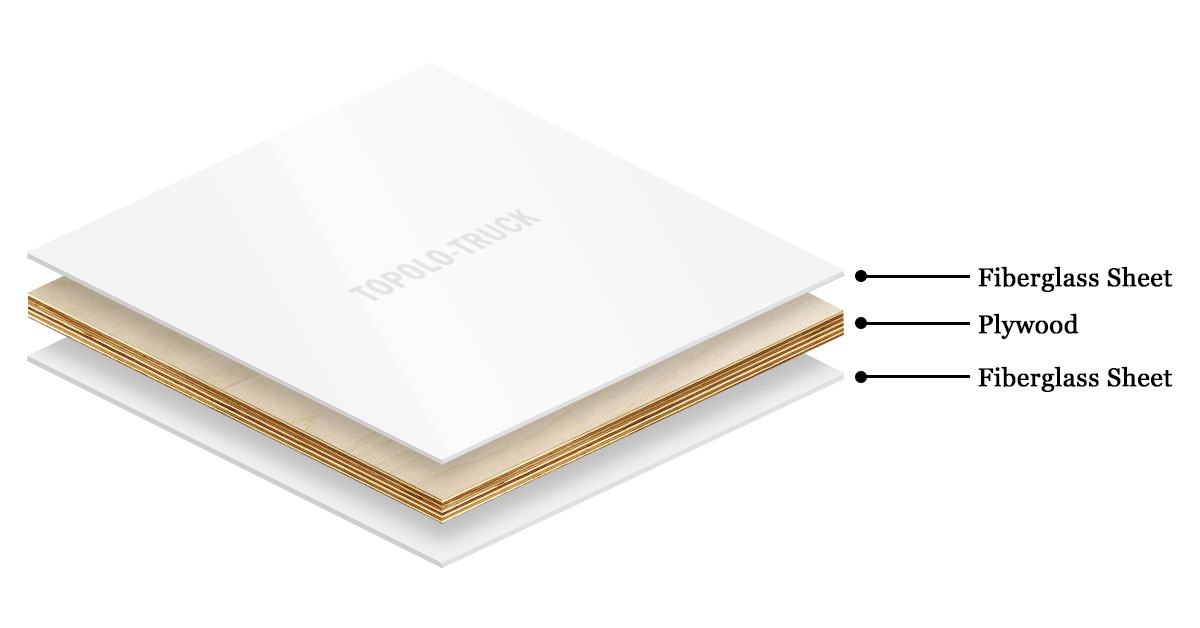

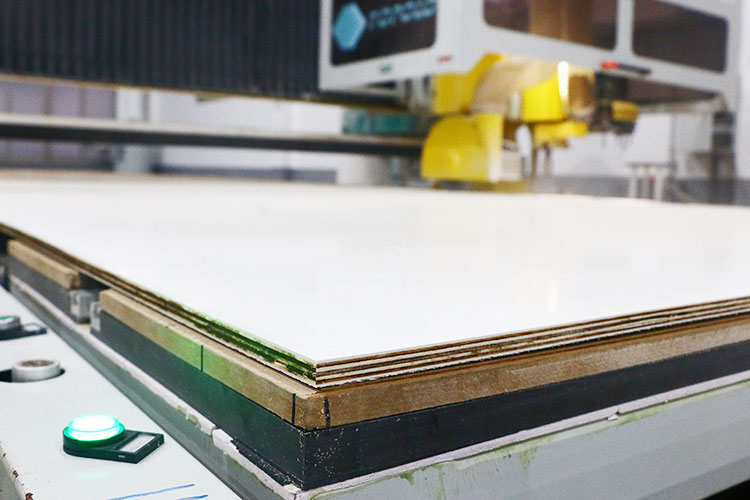

Structure of FRP Plywood Sandwich Panels

FRP plywood is a typical skin-core-skin structure, where the layers of materials are bonded together using a strong adhesive.

Thermosetting FRP Sheet & Thermoplastic FRP Sheet

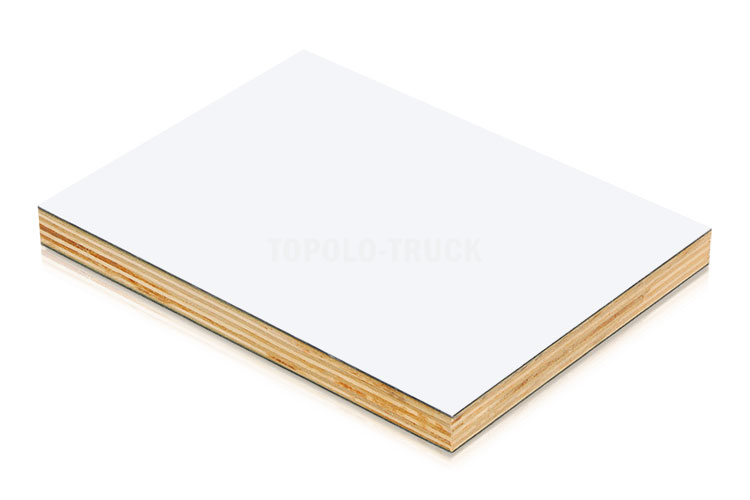

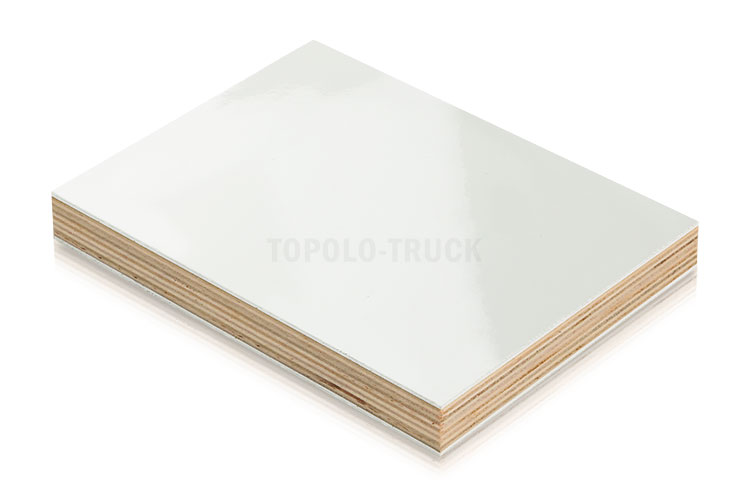

Thermosetting FRP Sheet

Thermoset FRP (GRP) materials offer higher overall rigidity and surface hardness. Their outer surfaces are typically finished with a high-quality gel coat, resulting in a smooth, flat appearance with a high level of gloss, giving the panels excellent visual appeal. However, the gel coat layer is relatively susceptible to scratches and wear over time. As a result, truck and trailer bodies using FRP skins require more careful and regular maintenance to preserve their appearance and long-term durability.

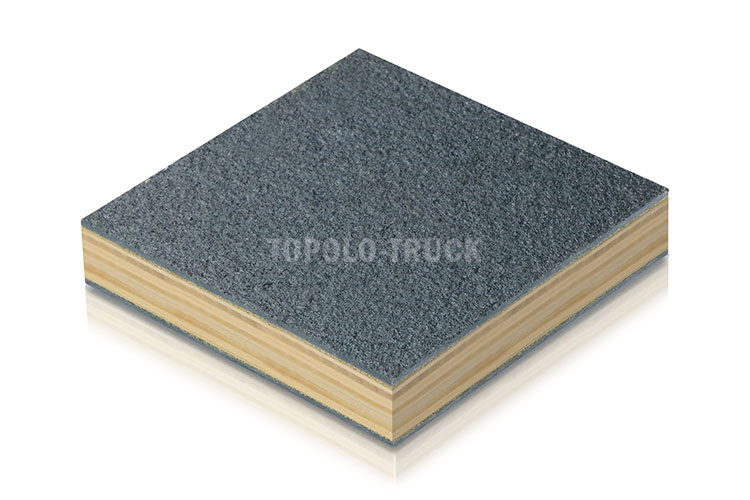

Thermoplastic FRP Sheet (CFRT Sheet)

CFRT sheets, as a new generation of thermoplastic FRP composite materials, offer high strength, lightweight characteristics, outstanding impact resistance, and superior corrosion resistance, providing a highly reliable and stable solution for vehicle body structures. Compared with traditional thermoset FRP, CFRT features greater toughness and higher overall structural rigidity, allowing it to withstand stronger external impacts and demanding operating conditions. However, its surface smoothness and decorative appearance are generally not as refined as those of gel-coated FRP. In addition, CFRT sheets can be efficiently laminated with polypropylene honeycomb cores through a thermoplastic lamination process, forming lightweight, high-strength, and structurally stable sandwich panels.

Our Customized Solutions

TOPOLO-TRUCK’s customized composite panel solutions help your vehicle projects achieve more efficient, safe, and flexible local production, enhancing overall operational efficiency. Customize prefabricated composite panel kits for your vehicle projects to enable localized, fast assembly.

We use a fully automatic composite panel production line to process FRP plywood quickly and efficiently. And the panel is machined by five-axis CNC. The surface of the finished product is flat, tightly bonded, and the edges are smooth.

Obtain FRP Plywood Panel Samples

We offer customized FRP plywood panel samples based on your provided materials or specific requirements for testing purposes.