What are expedition trucks?

Expedition trucks are vehicles designed specifically for long-distance travel, wilderness exploration, and camping. They typically consist of a rugged truck chassis and a specialized expedition cab. These trucks are designed not only for comfort and functionality but also with a strong emphasis on adaptability and durability, enabling them to handle harsh off-road environments and complex terrain.

The Importance of a Reliable Expedition Truck Box

As the core component of an expedition truck, the box body’s structure, materials, and design directly impact the vehicle’s performance during extended field driving. A reliable box body requires strong durability, excellent sealing, waterproofing, and shock resistance. To ensure the protection of the driver and equipment under extreme weather conditions, the expedition truck box body must be designed to guarantee high standards of durability and comfort.

TOPOLO-TRUCK is a leading global expert in truck body construction, providing practical and customized solutions for expedition truck and trailer manufacturers and dealers worldwide. Whether it’s a light-duty pickup or a heavy-duty truck, TOPOLO-TRUCK offers a perfectly matched body design. The company offers flexible manufacturing options, including CKD (Completely Knocked Down), SKD (Semi-Knocked Down), and CBU (Completely Built-up) to meet the needs of customers with varying manufacturing capabilities.

What are the common dimensions of expedition truck boxes?

The dimensions of expedition truck boxes typically vary depending on the vehicle type and design purpose. We manufacture boxes up to 12 meters in length.

| Length range | Common External dimensions (length × width × height, unit: m) |

| 3.2 – 4.0 m | 3.2 × 2.0 × 2.0 3.4 × 2.05 × 2.05 3.6 × 2.1 × 2.1 3.8 × 2.1 × 2.1 4.0 × 2.15 × 2.15 |

| 4.2 – 6.0 m | 4.2 × 2.2 × 2.2 4.4 × 2.25 × 2.2 4.6 × 2.25 × 2.25 4.8 × 2.3 × 2.3 5.0 × 2.3 × 2.3 5.2 × 2.3 × 2.35 5.5 × 2.35 × 2.35 6.0 × 2.35 × 2.4 |

| 6.2 – 7.5 m | 6.2 × 2.4 × 2.4 6.5 × 2.45 × 2.45 6.8 × 2.45 × 2.5 7.0 × 2.45 × 2.5 7.2 × 2.45 × 2.5 7.5 × 2.45 × 2.5 |

| 8.0 – 9.6 m | 8.0 × 2.45 × 2.5 8.4 × 2.45 × 2.55 8.8 × 2.5 × 2.55 9.0 × 2.5 × 2.55 9.6 × 2.5 × 2.6 |

The design of the expedition truck box

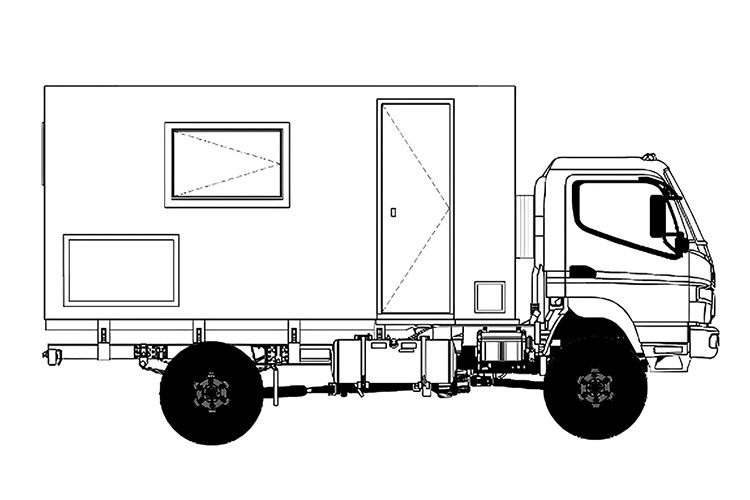

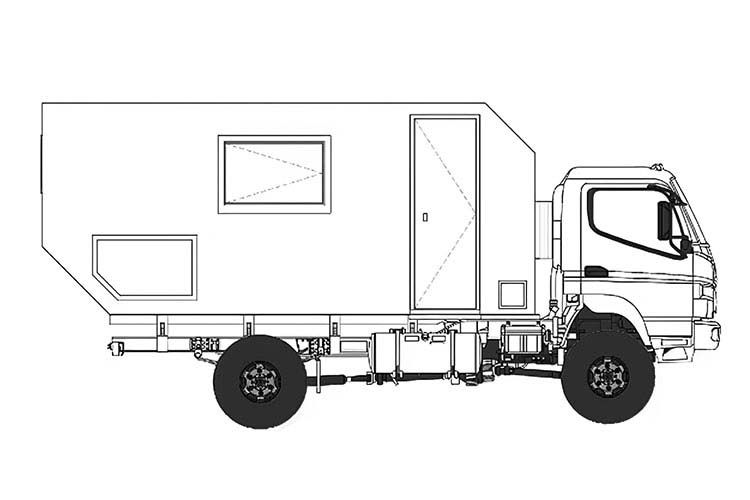

TOPOLO-TRUCK can also customize or optimize sketches according to customer needs, providing personalized design solutions. Expedition truck boxes typically come in two common shapes:

Standard rectangular box

This design is simple and practical, suitable for most standard expedition needs, and provides maximum utilization of internal space.

Departure angle box

This design is more suitable for off-road and complex terrain. The rear and bottom of the box are angled to reduce contact with the ground, improve passability, and perform exceptionally well on rough roads.

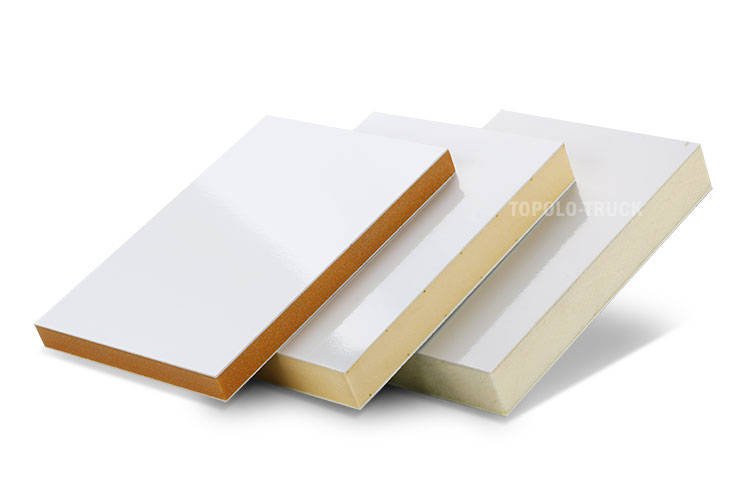

Expedition Truck Box Panel Material

Composite panels are the core material for constructing the expedition truck box, and their selection directly affects the vehicle’s structural performance, durability, and user experience. Therefore, choosing the right composite panels is crucial.

Framed Foam Core Composite Panel

The TOPOLO-TRUCK expedition truck box utilizes high-quality composite materials, ensuring the box’s sturdiness and durability. The lightweight, robust foam core composite panel offers excellent compressive strength and thermal insulation, ensuring the box’s thermal insulation and impact resistance.

Weather-Resistant Outer Skin

Using UV-resistant FRP sheets or corrosion-resistant aluminum alloy sheets as the weather-resistant outer skin of the composite panel, it withstands the effects of harsh weather conditions such as sun exposure, rain, snow, and hail, maintaining the stability of the box’s appearance and structure.

Insulating Foam Core

XPS (extruded polystyrene), PVC (polyvinyl chloride), and MPP (microcellular polypropylene) foam cores combine three major advantages: lightweight, thermal insulation, and water resistance. This reduces the overall vehicle weight and fuel consumption, while also insulating against external hot and cold air to maintain a stable internal temperature. Simultaneously, its water-resistant properties prevent mold and corrosion inside the box in humid environments.

Panel Features

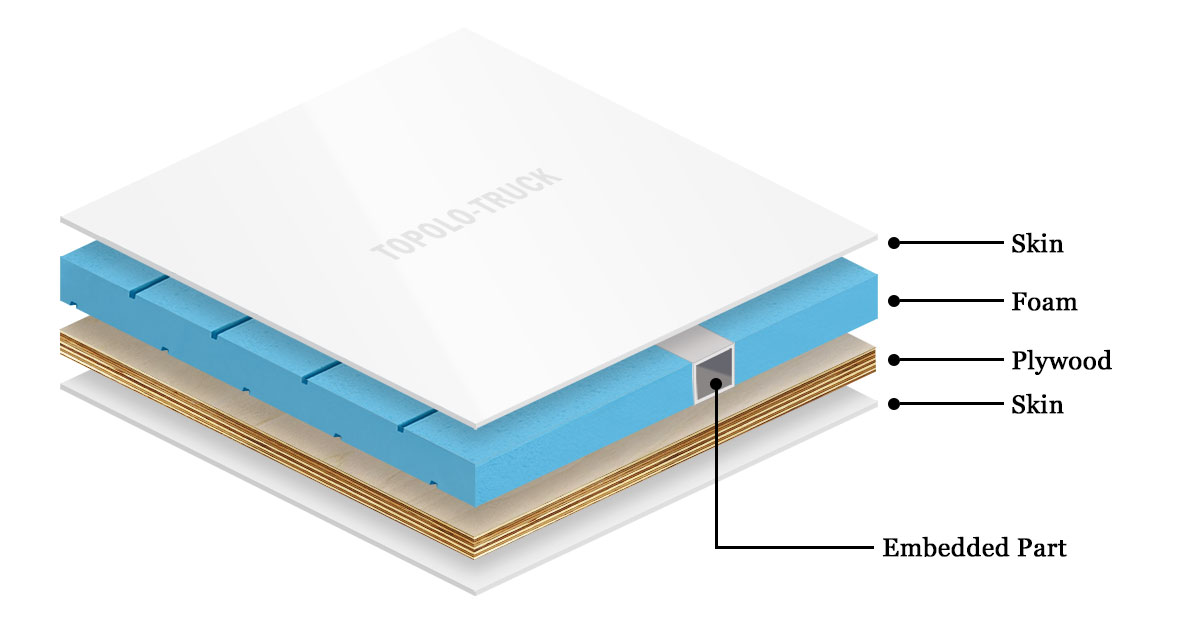

Reinforced Structure with Embedded Frame

A high-strength frame made of materials such as timber, aluminum profiles, and steel is embedded within the cargo box, significantly improving the panel’s impact and bump resistance. Even during long journeys on rough terrain, the structural stability of the cargo box remains guaranteed.

Embedded Electrical and Plumbing Piping

Hollow pipes embedded within the panel facilitate the installation of integrated electrical wiring and water pipes. This design keeps the interior of the cargo box neat and aesthetically pleasing.

Thickened Reinforced Flooring

The reinforced flooring improves insulation, freeze resistance, and pressure resistance. Even in extremely cold environments with temperatures dropping to tens of degrees below zero, it will not crack or deform.

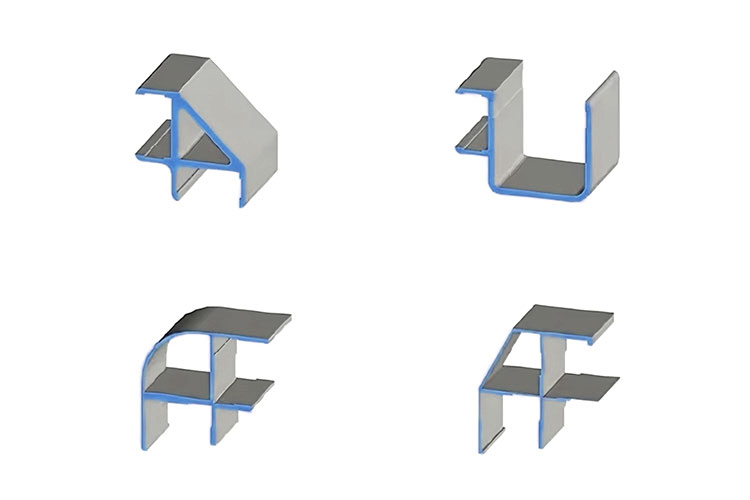

How to choose the connection method for composite panels

Metal Profile Connection

By abandoning the traditional outer frame connection method, this design uses metal profiles to directly splice the panels together. This approach not only simplifies the assembly process and improves modular assembly efficiency, but also reduces the extra weight added by the outer frame, while giving the box a cleaner and smoother appearance.

Integrated Frame

This integrated structural framework is made from high-strength rigid steel beams welded together and treated with a special anti-corrosion coating, ensuring exceptional strength and stability during long-distance treks. Optimized welding techniques and advanced corrosion protection technologies ensure that it maintains outstanding durability and fatigue resistance even in extreme environments, effectively handling prolonged loads and wear. Additionally, the precise design and material selection further enhance the overall reliability and safety, ensuring stable performance over extended periods even under harsh operating conditions.

Subframe

The subframe is a key load-bearing component connecting the adventure truck body and the chassis. Made of high-strength steel or aluminum alloy, it is fastened to the chassis with nuts, ensuring both load-bearing capacity and mounting stability.

Its core innovation lies in the flexibly adjustable spacing between crossbeams. Breaking the limitation that traditional subframes can only fit a single type of chassis, it is compatible with light, medium and heavy-duty truck chassis of different brands and wheelbases, greatly improving product adaptability and reducing customers’ customization costs.

Customized Accessories

To comprehensively meet the diverse application needs of our expedition truck users, we offer a wide range of customized truck bed accessories, covering various functional doors, windows, sunroofs, storage compartments, ladders, and more.