Enclosed cargo trailers are widely used in transportation for their ability to offer protection and security for goods. Especially in North America, Europe, South America, and Australia, enclosed cargo trailers are very popular, primarily due to their robust cargo protection features, ensuring that goods are unaffected by weather or external environmental factors during transport. They provide excellent protection for goods in both cold and humid regions.

Choose Our Trailer Building Solutions

If you’re planning to build an enclosed cargo trailer, we offer full support from initial design to final construction. Whether you’re focused on custom dimensions, materials, or features, our experienced team can assist you in creating a trailer tailored to your needs.

☑ Lightweight

Optimized trailer design combined with the application of new composite materials significantly reduces vehicle weight, thereby improving transportation efficiency and fuel economy.

☑ Durable

The trailer structure offers excellent impact and corrosion resistance, which can effectively extend the service life of the trailer and reduce maintenance costs.

☑ Cost-effectiveness

Composite materials have significantly lower production and processing costs, offering a more cost-effective solution. Modular design also allows for more efficient trailer construction.

Choices of materials for enclosed trailer bodies

As the demands of the logistics industry continue to evolve, the optimization and development of enclosed cargo trailers has become a crucial issue in the industry. The choice of body materials directly impacts the trailer’s weight, durability, and transportation efficiency. The TOPOLO-TRUCK new composite material panel offers significant advantages over traditional metal composite panels.

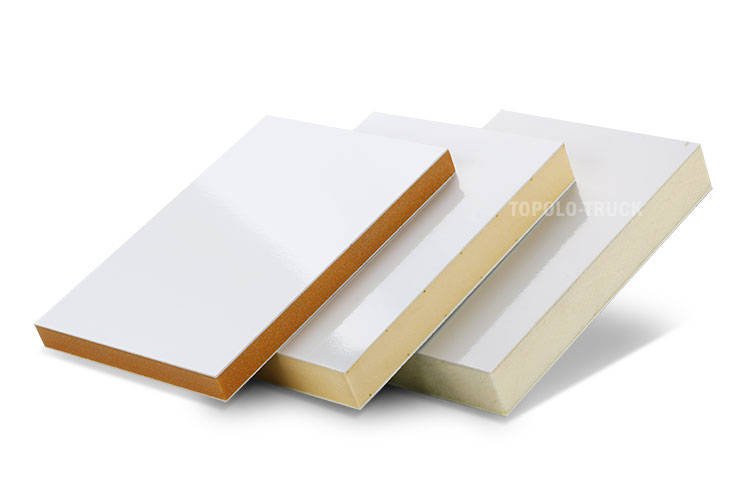

Insulated Foam Core Composite Panels

Foam-core panels are commonly used for their thermal insulation properties, making them suitable for transporting temperature-sensitive goods while maintaining a lightweight structure.

Lightweight Polypropylene Honeycomb Core Panels

These panels are lightweight yet strong, offering a great combination of strength, insulation, and weight reduction. They are an ideal choice for trailers where reducing weight is important without sacrificing structural integrity.

Waterproof Plywood Composite Panels

This is an affordable option; waterproof and flame-retardant plywood combined with fiberglass reinforcement offers excellent strength and durability.

Common Rear Door Designs for Enclosed Trailers

The design of the rear door of an enclosed trailer directly affects the efficiency and safety of loading and unloading goods.

Hinged Wing Doors

Simple design, suitable for loading and unloading small to medium-sized goods. Wing doors can open in a small space, suitable for scenarios requiring quick opening and closing.

Roll-Up Doors

Using a roll-up structure, the entire trailer can be fully opened, suitable for transporting larger items. This type of door is typically used in situations where goods frequently enter and exit.

Ramp Doors

Commonly used for transporting large, heavy goods, such as cars, motorcycles, snowmobiles, etc. Ramp doors allow heavy items to be easily pushed onto the trailer, reducing the difficulty and risk of manual handling.

Customized Trailer Body Parts

Any parts and accessories can be obtained directly from us. By providing custom services, you no longer need to repeatedly source various components from the market, saving you both intermediary steps and additional costs. Additionally, our prices are highly competitive, ensuring that you can enjoy high-quality custom parts while also saving on costs.

- Door frame.

- Door seal.

- Hinges.

- Edge profiles.

- Corner caps.

- Signal lights.

- Lighting lights.

- Cargo rails.

- Cargo rods, etc.

Trailer Chassis Support Services

Available in single-axle, dual-axle, and tri-axle configurations. Flexible selection based on load requirements (single-axle load capacity: 5-8 tons, dual-axle load capacity: 10-15 tons, tri-axle load capacity: 18-25 tons).

Material Selection

High-strength Q-series steel, after being treated with pickling, phosphating, and galvanizing or painting for rust prevention, can withstand more than 1,000 hours of salt spray testing and is suitable for harsh environments such as humid, coastal, and high-salt-spray conditions.

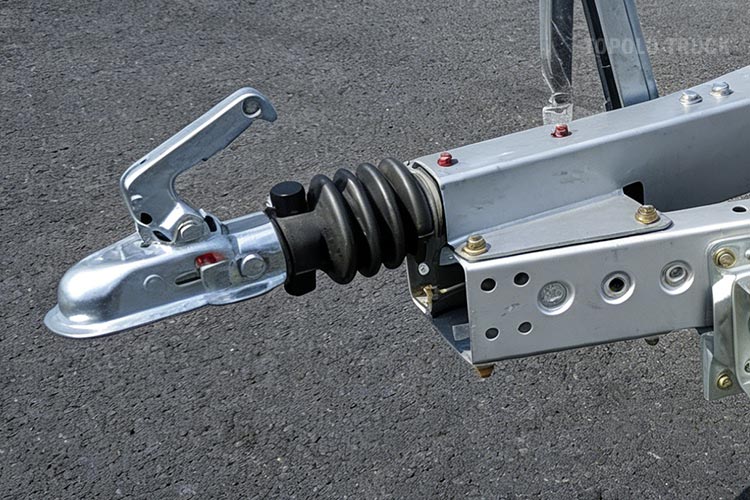

Tow Bar Design

Customizable production to fit different brands and models of towing vehicles (such as pickup trucks, cargo trucks, and specialized towing equipment). Features a universal joint structure, providing flexible steering and reducing bumps and stress damage during travel.

Tire Compatibility

Includes various sizes such as 16 inches, 17.5 inches, and 19.5 inches. Options for all-steel radial tires and off-road anti-slip tires are available, making it suitable for highway transportation, rural dirt roads, and rough construction site surfaces.