Duraplate Panels

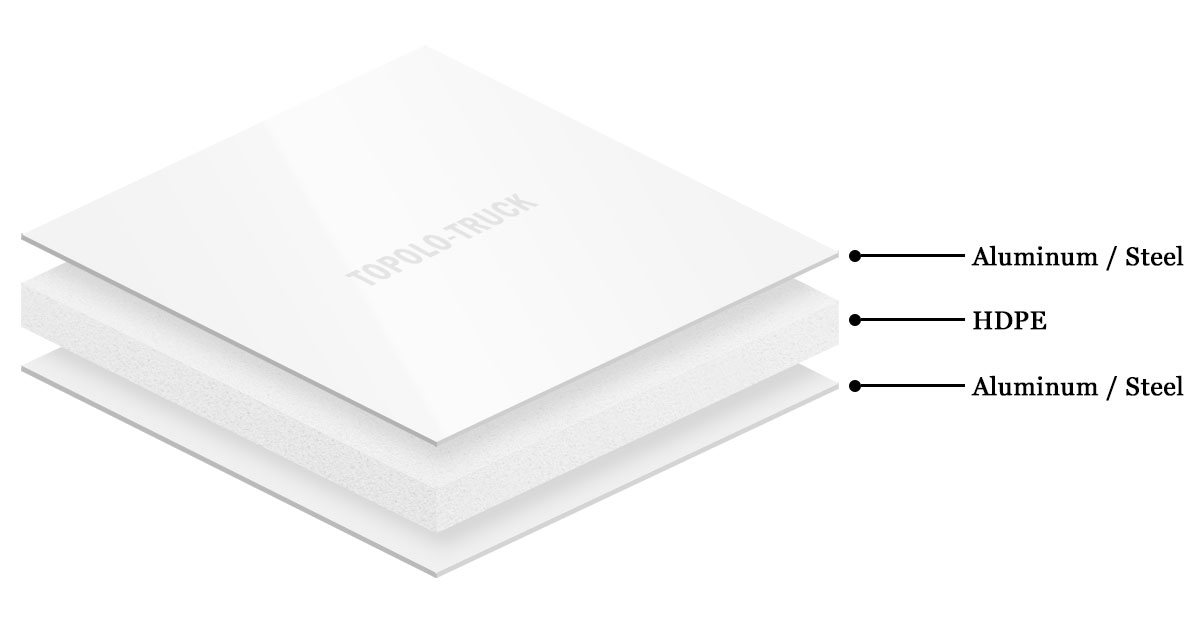

Duraplate panels are a hard composite panel known for its resistance to corrosion, impact and abrasion. It consists of a core material (high-density polyethylene (HDPE)) sandwiched between two thin sheets of metal (usually aluminum or steel). This sandwich structure provides excellent structural strength, being stronger than foam core sandwich panels while being relatively lightweight compared to solid metal panels.

Duraplate panels are widely used in trucks and trailers, It provides strong structural support for the truck body, helping to improve the truck’s load-carrying capacity and fuel efficiency, and can withstand the challenges of long-distance transportation and heavy cargo. Inside the cargo body, these panels protect the integrity of the cargo by effectively resisting impacts, vibrations and other forms of physical damage.

Schematic Diagram

Aluminum or steel sheets and HDPE inner core material are laminated using a hot-pressing process. This process tightly bonds the skin and inner core material, forming a robust and stable composite structure.

In short, the advantages of Duraplate Panels are:

☑ High strength

They are resistant to impacts, vibrations, and other forms of physical damage, resulting in extended service life.

☑ Lightweight Design

Despite their superior strength and durability, Duraplate panels are relatively lightweight. This makes them ideal for applications such as trucks, containers and more as they can help reduce overall weight, thereby saving on fuel costs and increasing payload.

☑ Corrosion Resistance

Duraplate skins are typically made of steel or aluminum with a pre-coated surface that provides excellent corrosion resistance. This corrosion resistance allows it to maintain its appearance and performance under a variety of environmental conditions.

☑ Non-absorbent

Its metal outer layer provides an effective barrier, preventing moisture from penetrating inside the panel. At the same time, the non-absorbent nature of the core material also helps prevent the penetration and absorption of moisture.

Specifications

| Composition | Skin | Aluminum alloy. |

| Coated Steel. (GI, GL, PPGI, PPGL) | ||

| HDPE | Density: 0.941 – 0.960 g/cm³. | |

| Size | 1220 x 2440mm, or Customized. | |

| Thickness | 6.0 – 12mm, or Customized. | |

What is HDPE material?

HDPE (High-Density Polyethylene) is a common thermoplastic known for its high strength, chemical resistance, and good weather resistance. Compared to LDPE (Low-Density Polyethylene), HDPE has a more compact molecular structure, making it stronger, more rigid, and suitable for heavier-duty applications.

Aluminum or Steel Skin

- If you require a stronger, more robust material for heavy-duty applications and weight is not a major concern, steel skin duraplate may be a suitable option. Steel offers excellent durability and impact resistance, making it particularly suitable for vehicles that need to withstand rough handling or heavy loads.

- If lightweight, corrosion resistance, and fuel efficiency are your priorities, aluminum skin duraplate is ideal. It reduces weight, improves vehicle efficiency, and protects against environmental factors such as rain and moisture.

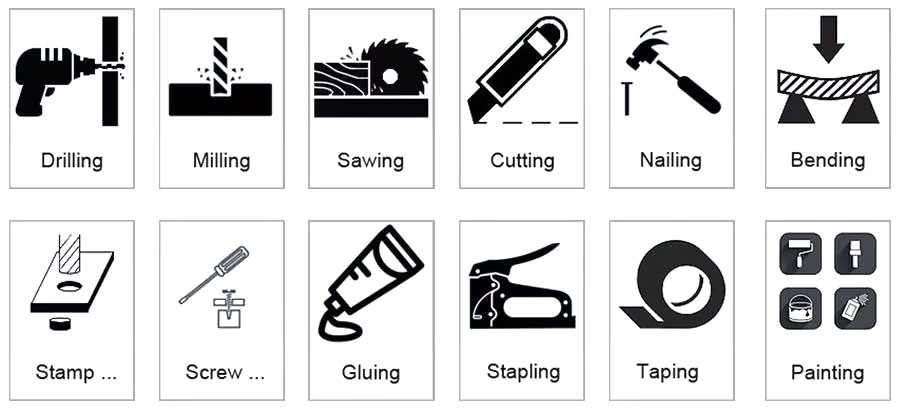

Post-processing

Duraplate panels offer outstanding machinability, enabling easy processes such as drilling, milling, sawing, cutting, nailing, bending, stamping, screwing, gluing, stapling, taping, and painting. This versatility in machining provides great flexibility in body design while significantly simplifying the assembly process, enhancing production efficiency. Whether for custom vehicle body designs or large-scale manufacturing, Duraplate meets various production and assembly needs, ensuring its widespread use in the modern transportation industry.