CFRT Sheets for Trailer & Truck Bodies

What is CFRT Sheet?

CFRT (Continuous Fiber Reinforced Thermoplastic) sheets are a new type of high-performance thermoplastic composite sheets, belonging to a branch of fiber reinforced polymers (FRP). However, they are essentially different from traditional thermosetting FRP sheets in terms of structure, performance and application scenarios.

Highlight Advantages

Compared with traditional thermosetting FRP sheets and metal plates, the advantages of CFRT sheets are concentrated in the following aspects.

☑ Ultimate Lightweight

With continuous fibers as the reinforcement and thermoplastic resin as the matrix, it ensures high strength while its density is much lower than that of steel, even lower than that of some aluminum alloy materials. The lightweight effect is remarkable, which can greatly reduce the self-weight of equipment.

☑ Excellent Durability

It has outstanding impact resistance and scratch resistance, and is not easy to be damaged due to external collision or friction. Meanwhile, it has excellent rigidity and is not easy to deform during long-term use, with a service life far exceeding that of traditional thermosetting FRP sheets.

☑ Maintenance-free Performance

The thermoplastic matrix has good corrosion resistance and weather resistance. It is not easy to age or degrade in harsh environments such as humidity, acid-base, high and low temperatures, and does not require frequent maintenance in daily use, reducing operation and maintenance costs.

☑ Recyclable and Reusable

Different from the defect that thermosetting FRP cannot be reshaped for the second time after forming, CFRT sheets can be reshaped by heating and softening. They are environment-friendly composite materials, conforming to the development trend of green manufacturing.

Structure and Forming Process

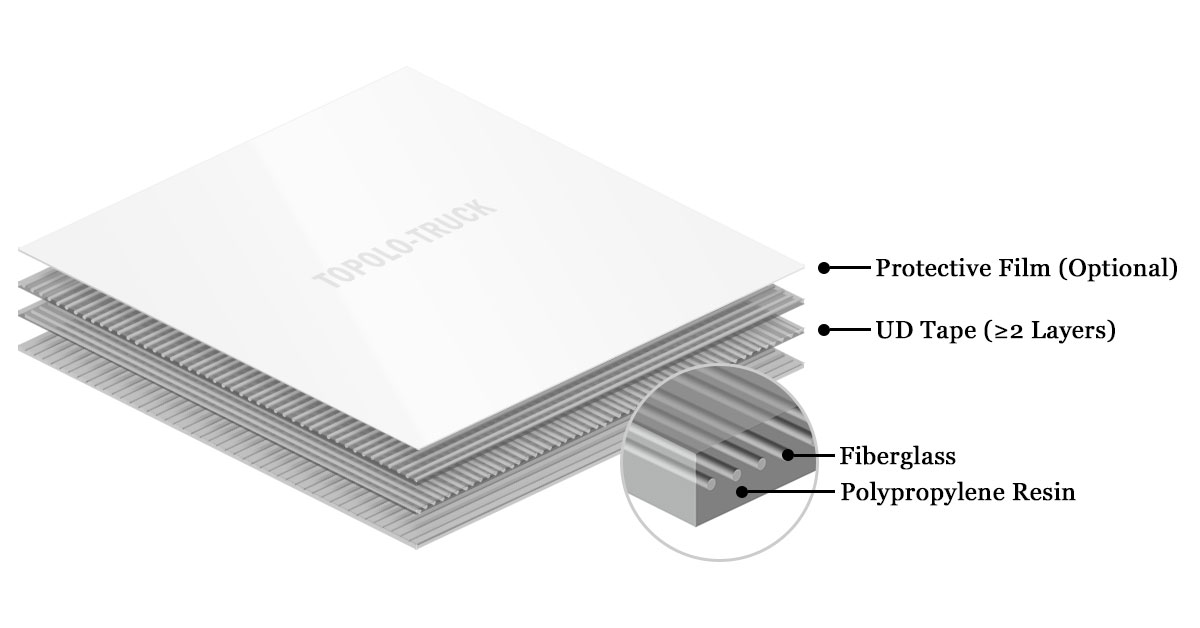

Different from the “fiber + thermosetting resin curing” mode of thermosetting FRP, the forming process and structural characteristics of CFRT sheets are as follows:

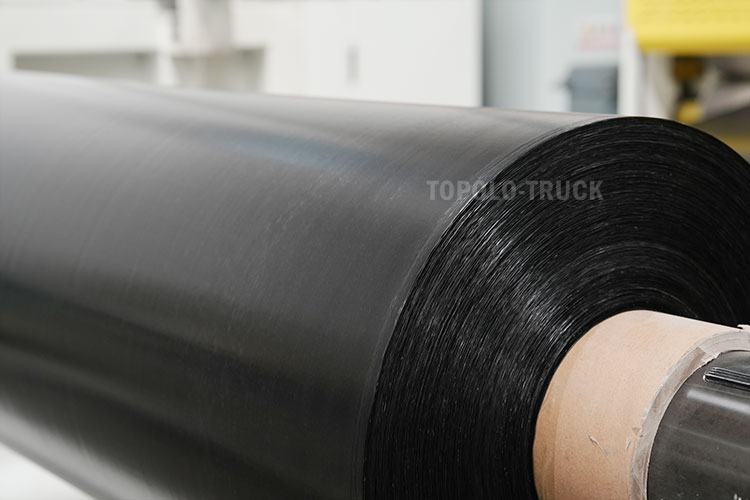

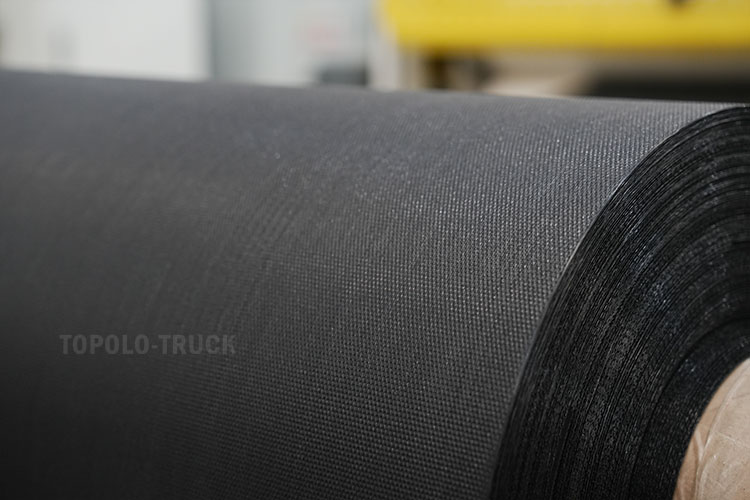

- Basic Raw Materials: Continuous long fibers are used as the reinforcement phase, and thermoplastic resins are used as the matrix phase.

- Lay-up Design: Continuous fiber prepreg tapes impregnated with thermoplastic resin are laid in multiple layers at preset angles (such as 0°, 90°, ±45°, etc.). The lay-up angle and number of layers can be adjusted according to the actual mechanical performance requirements.

- Composite Forming: The layers of prepreg tapes are fused into a whole under high temperature and pressure through the hot lamination process, finally forming an integrated CFRT sheet.

This lamination forming process not only ensures the structural uniformity of the sheet, but also can accurately match the mechanical requirements of different scenarios by adjusting the lay-up scheme.

Application of CFRT sheets in truck and trailer bodies

In the commercial vehicle field, CFRT sheets are ideal materials for realizing body lightweight. They are mainly used to replace traditional metal plates and thermosetting FRP sheets as the skin of box-type body composite panels.

Refrigerated Boxes

With good structural stability and weather resistance, it can adapt to the low-temperature working environment of refrigerated boxes. Meanwhile, lightweight can reduce refrigeration energy consumption and transportation fuel consumption.

Dry Cargo Boxes

The impact resistance and deformation resistance can protect the goods inside the box, and the maintenance-free advantage can reduce the long-term operation costs of logistics enterprises.

Other Commercial Vehicle Bodies

Such as ambulance boxes, mobile restrooms, catering trailers, etc. CFRT sheets help commercial vehicles meet the industry development requirements of lightweight, energy saving and consumption reduction.

Specifications

| Fiber Type | Continuous glass fiber. |

| Resin Type | Thermoplastic polypropylene. |

| Fiber Content | 40%-70%. |

| Thickness | 0.7-2.0mm. |

| Width | Maximum 2.8m . |

| Length | 200-500m/roll. |

Surface Treatment Solutions

According to the appearance and functional requirements of application scenarios, CFRT sheets can be provided with a variety of surface treatment methods.

No Treatment

- Features: Retaining the original surface state of the sheet.

- Application: Suitable for internal structural parts with no special requirements for appearance.

Polyester Protective Film Coating

- Features: The protective film is available in two textures: matte and glossy, and can also support color customization. It can not only protect the sheet surface from scratches during processing and transportation, but also meet the appearance color matching requirements of the vehicle body.

- Application: Internal and external skinning of wall panels.

Embossing Treatment

- Features: Anti-slip texture are formed on the surface through the embossing process.

- Application: Suitable for box body floors, step pedals and other parts that require anti-slip performance.

CFRT vs Thermosetting FRP Sheets

| Performance Dimension | CFRT Sheets | Thermosetting FRP Sheets |

|---|---|---|

| Durability | Strong impact resistance and scratch resistance, long service life | Weak impact resistance, prone to local damage |

| Deformation Resistance | Excellent rigidity, not easy to deform during long-term use | High hardness but insufficient rigidity, prone to slight deformation under stress |

| Surface Flatness | Good surface flatness, meeting general appearance requirements | Flatter and smoother surface, suitable for scenarios with extremely high appearance requirements |

| Recyclability | Thermally reshapable, environmentally friendly and recyclable | Irreversible after forming, difficult to recycle and reuse |

| Processing Flexibility | Can be secondary formed after heating, suitable for processing complex structures | Cannot be secondary processed after forming, with high difficulty in structural adjustment |

Common Types of CFRT Composite Panels

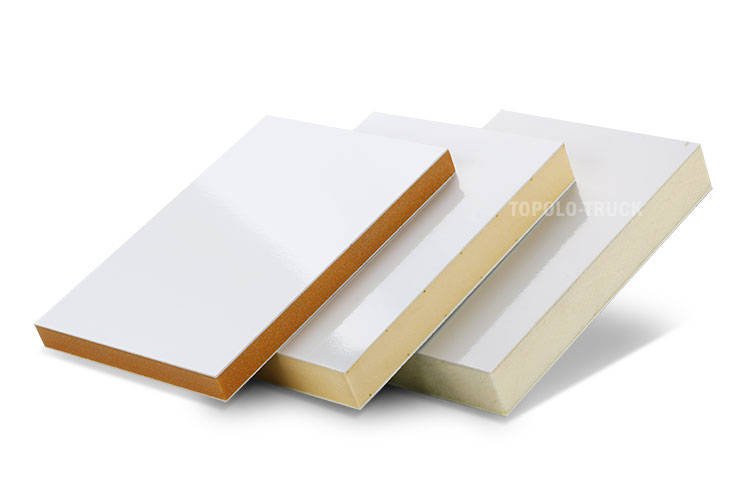

CFRT sheets can be compounded with various core materials to form composite panels with different functions, meeting the needs of heat preservation, heat insulation and lightweight in different scenarios.

CFRT + Foam Core Composite Panels

The core materials of these composite panels typically include PET (Polyethylene Terephthalate), XPS (Extruded Polystyrene), PVC (Polyvinyl Chloride), PU (Polyurethane), and MPP (Modified Polystyrene) foams. These materials not only offer excellent thermal insulation properties but also provide significant advantages in terms of lightweight design. Due to their outstanding heat isolation capabilities and ability to reduce the overall vehicle weight, these composite panels are widely used in the manufacturing of various types of truck and trailer bodies.

CFRT + PP Honeycomb Core Composite Panels

The polypropylene honeycomb core is light in weight and high in compressive strength. After being compounded with CFRT sheets, it has both lightweight and high rigidity, suitable for dry cargo transport truck boxes and can bear high load impact.

CFRT + Plywood Core Composite Panels

After compounding, the bending resistance of the panel is greatly improved, while retaining certain lightweight advantages. It is suitable for special vehicle compartments or temporary storage boxes with high bearing capacity requirements.