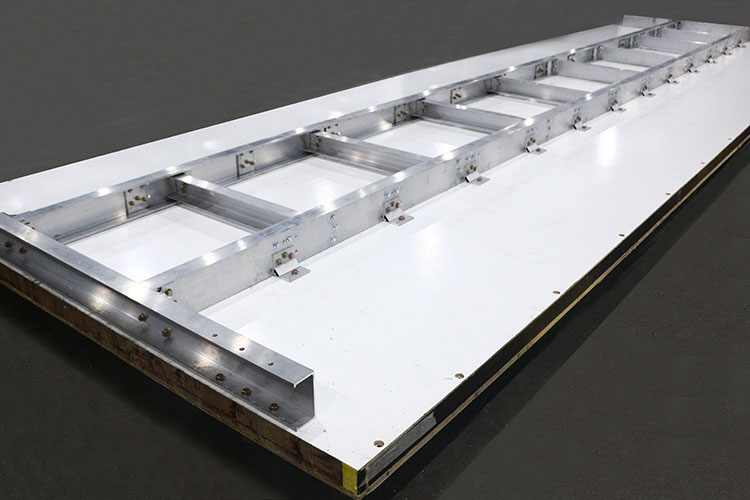

The aluminum truck subframe is made entirely of aluminum alloy material. Its strength is very suitable for structural applications and has a good combination of properties. Using aluminum truck subframes can not only improve the stability of the truck, but also protect the truck body while ensuring the safety of the cargo like conventional subframes. In addition, because aluminum alloy has good corrosion resistance, mechanical properties, formability and weldability, it can be lighter than steel and have better load-carrying capacity. The extrusion forming technology used can precisely control every detail of the aluminum truck subframe, reducing production costs while achieving a high degree of standardization of components.

DESCRIPTION

Features of All-aluminum Truck Subframe

- Corrosion resistance: The frame is made of 6061 aluminum, which has good oxidation resistance. Even without the use of baking paint, its surface can withstand the test of various outdoor climates.

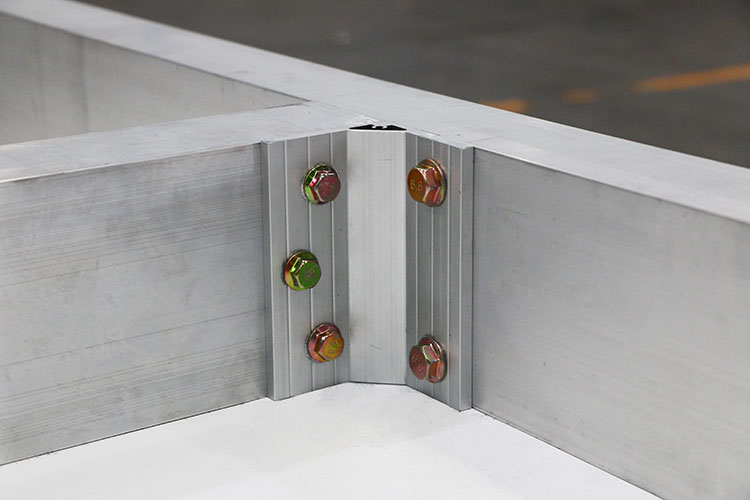

- Screw connection: All parts are connected together using screws, making assembly easy and disassembly simple.

- Reinforcement accessories: Special reinforcement accessories are used between the cross beams and longitudinal beams to further strengthen the structure of the subframe.

- High precision: Use high-precision molds for mass production to minimize errors.

- High load capacity: The aluminum subframe manufactured using the aluminum extrusion process is much stronger than the stamped galvanized steel subframe. The 8m-long aluminum subframe can carry more than 15 tons of weight.

Quick Assembly Aluminum Subframe

Applications

Aluminum truck subframe is extremely versatile and can be widely used in different models such as refrigerated trucks, dry trucks, tipper trucks and so on. At the same time, it can also be adapted to almost all mainstream truck brands such as FAW, Ford, Isuzu, etc.