Reefer truck side panels play a key role in maintaining the required temperature of the cargo. These side panels are designed to provide insulation and prevent the transfer of heat to the inside and outside of the vehicle. TOPOLO has leading insulation box manufacturing technology. Our reefer truck side panels have the characteristics of lightweight, high strength, no seams, beautiful appearance, good thermal insulation, and corrosion resistance.

Specifications

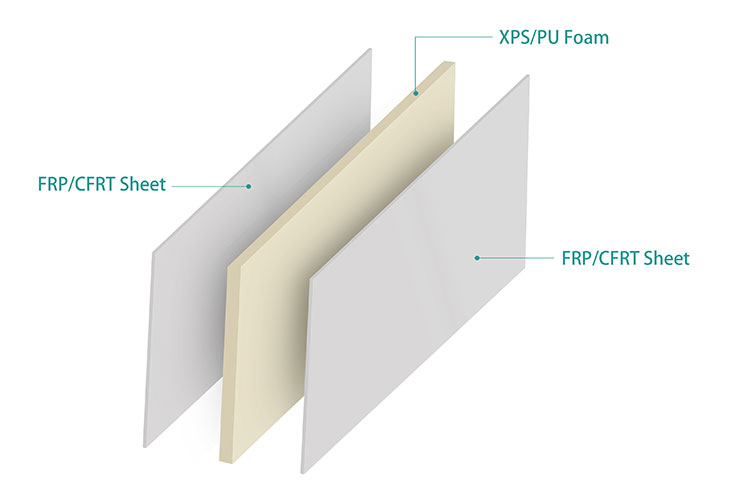

- Skin material: FRP/CFRT (customized: 0.7~5.0mm).

- Core material: XPS/PU.

- Length: ≤12mm.

- Width: ≤3.0m.

- Thickness: 10~120mm (customized).

- Finish: Glossy/Matte.

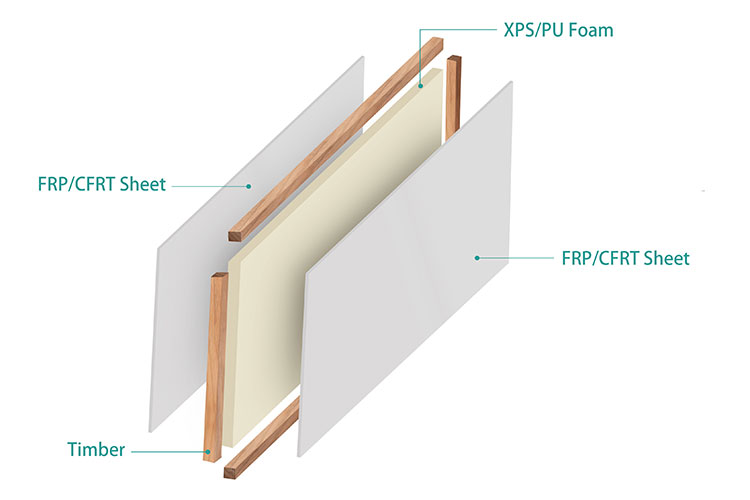

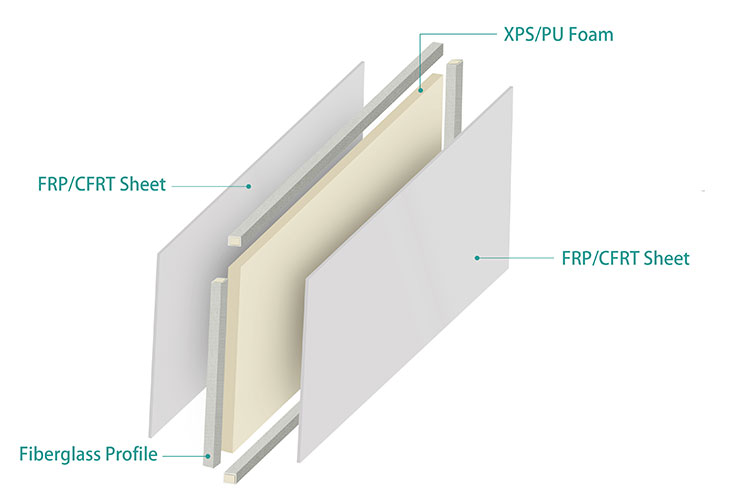

- Frame material: aluminum, steel, fiberglass, wood, etc.

Choose Reefer Truck Side Panels in TOPOLO

Our professional vehicle design team has many years of experience in Reefer truck box production and combines it with the most advanced composite panel production technology in the world. Let us be favored by Reefer truck manufacturers all over the world in the industry.

- Modular CKD reefer truck box.

- Thermal insulation and waterproof.

- Lightweight and high strength.

- Antibacterial and corrosion resistant.

- Efficient and fast assembly.

First, we provide premium raw materials.

- The side panels of reefer trucks use polyurethane (PU) or extruded polystyrene (XPS) foam as core materials. They have excellent thermal insulation properties and help maintain a stable temperature in the cargo area.

- Antibacterial fiberglass is used as the skin material. TOPOLO has also developed a new type of FRP – CFRT, whose compressive and tensile strength is several times higher than ordinary FRP.

- We provide a variety of internal structural strengthening components, which are customized according to the application requirements of reefer trucks to enhance the strength of the side panels while reducing heat transfer.

Secondly,we have advanced refrigeration panel production equipment.

Thirdly, we provide better solutions for reefer truck side panels.

- The panel uses a typical sandwich structure with a simple structure and is suitable for small reefer truck boxes that do not require high strength.

- The use of timber as the frame structure of sandwich panels can greatly provide the strength of the panels and provide sufficient connection support between panels. The excellent nail-holding strength of timber facilitates the installation of other accessories.

- Sandwich panels using high-strength fiberglass materials as frame structures are much stronger than sandwich panels with wood structures. Moreover, fiberglass parts do not absorb water, rot, or deform, and their normal service life can reach 20 to 30 years.

- It is developed on the basis of fiberglass frame structure sandwich panels, and E-Tracks are installed inside the sandwich panels. This advanced design method not only allows the E-Tracks to be installed more firmly but also keeps the surface of the reefer truck side panels smooth, reducing the risk of damage to the cargo and the E-Track system itself.