Day Old Chick Transport Truck Bodies

Home >> Truck Bodies

A day-old chick truck, also known as a baby chick transport truck or young chick transportation vehicle, is specially designed for the professional transport of live hatchlings. It is widely used for transporting day-old chicks, ducklings, goslings, as well as other sensitive biological cargo such as flowers and seedlings.

We offer fully customized day-old chick transport truck bodies in lengths ranging from 4 meters to 9 meters, tailored to meet different customer requirements. Customization options include box dimensions, internal layout, ventilation systems, insulation structures, and loading capacity, ensuring optimal transport conditions for various poultry types and operational needs.

Component Configuration

- Front panel: Large fan vent.

- Side panels: Upper window + sunshade.

- Roof panel: Small fan vent + center safety window.

- Rear door: Center ventilation vent.

- Floor: Anti-slip patterned aluminum plate with drainage channels.

- Interior: Stainless steel storage rack; aluminum alloy rails; dual side pillars; roof hooks.

Box Body Sizes

| Truck Body Length | Inner Length (mm) | Inner Width (mm) | Inner Height (mm) | Typical Chassis | Estimated Chick Capacity* |

|---|---|---|---|---|---|

| 4.0 m | 3800 | 2100 | 2200 | Light truck (4×2) | 30,000 – 40,000 |

| 5.2 m | 5000 | 2150 | 2300 | Light / Medium truck | 45,000 – 60,000 |

| 6.2 m | 6000 | 2200 | 2400 | Medium truck | 65,000 – 85,000 |

| 6.8 m | 6600 | 2300 | 2450 | Medium truck | 85,000 – 100,000 |

| 7.6 m | 7400 | 2350 | 2500 | Medium / Heavy truck | 100,000 – 130,000 |

| 8.6 m | 8400 | 2400 | 2600 | Heavy truck | 130,000 – 160,000 |

| 9.0 m | 8800 | 2450 | 2600 | Heavy truck | 160,000 – 200,000 |

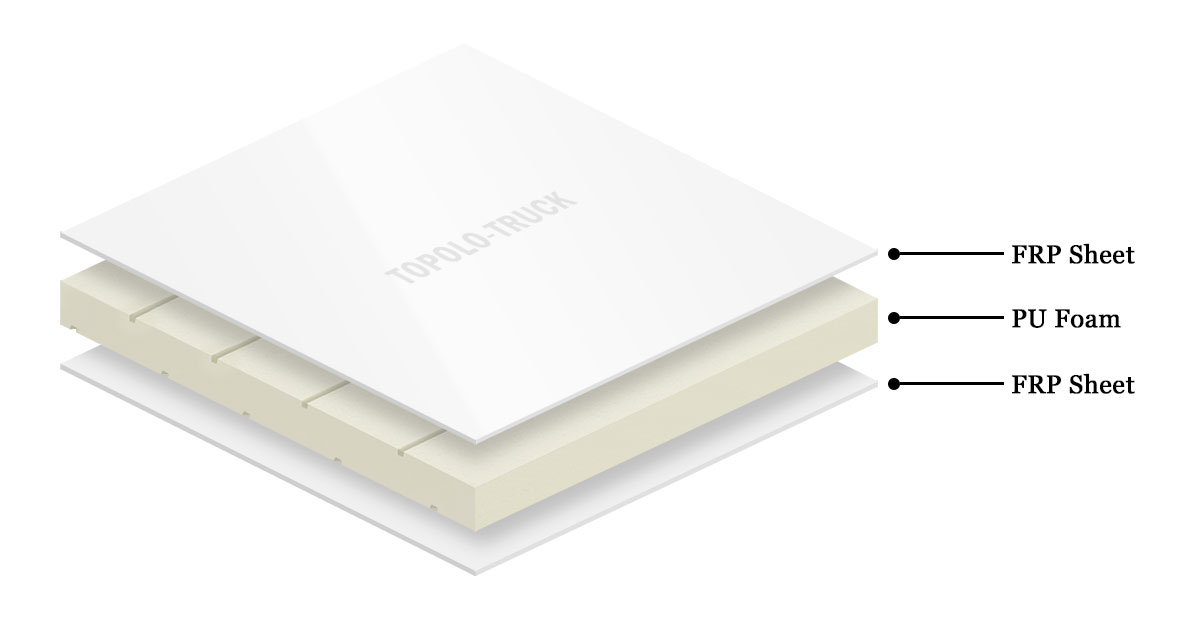

Box Body Composite Panels

Thermal Insulation and Antibacterial

Our chick transport truck bodies are manufactured using an integrated sandwich composite panel construction, ensuring excellent structural integrity, airtightness, and thermal continuity. This one-piece design effectively eliminates cold bridges, water leakage, and hygiene blind spots commonly found in traditional assembled structures.

The integrated FRP-PU-FRP sandwich panel structure not only creates a clean, safe, and temperature-stable environment for day-old chicks, but also plays a critical role in ensuring the reliable and efficient operation of heating, ventilation, and temperature-control systems, making it an ideal solution for professional chick transport vehicles.

- Both the inner and outer skins are made of hygienic gel-coat fiberglass (FRP), featuring a smooth and non-porous surface. The FRP skins provide outstanding water resistance, stain resistance, corrosion resistance, and easy cleaning, effectively preventing bacterial growth and fully meeting the strict hygiene requirements for day-old chick transportation, while significantly reducing maintenance and cleaning costs.

- The core insulation layer is composed of high-quality closed-cell polyurethane (PU) foam, offering a high closed-cell ratio and low thermal conductivity. This ensures excellent thermal insulation performance and stable internal temperatures during long-distance transport, minimizing the impact of external climate fluctuations on chick health.

Safe Design

- Internal shock-proof design:The internal suspension design prevents the vibrations generated by the truck from causing damage to day-old chickens during driving.

- Ventilation design: Sufficient ventilation windows need to be provided inside the truck to ensure air circulation.

- Aluminum edging: The box edging material uses aluminum extrusions, which is both strong and aesthetic.

Supporting Services

Air Circulation & Ventilation Control System

Forced Air Exhaust System

High-efficiency exhaust fans continuously remove heat, excess humidity, carbon dioxide, and ammonia generated during transportation, maintaining a fresh and oxygen-rich internal environment.

Multi-stage Filtration System

Incoming air is filtered to effectively block dust, feathers, microorganisms, and external contaminants, reducing the risk of disease transmission and ensuring biosecurity during chick transportation.

Temperature Control System

Cooling Mode

High-performance refrigeration units rapidly reduce and stabilize compartment temperature during hot weather, preventing heat stress and dehydration of chicks.

Heating Mode

Electric or fuel-powered heating systems provide gentle and uniform warmth in cold environments, ensuring chicks remain within the optimal temperature range after hatching.