FRP composite panels are being used more and more in box truck bodies, whether refrigerated or dry cargo. FRP composite panels are generally welcomed by truck manufacturers for their superior performance. The advantages of FRP truck panels are light, strong, waterproof, corrosion-resistant, and heat-insulating. Whether it is performance or economic benefits, it is far superior to other materials.

What is FRP?

FRP ( fiberglass reinforced plastic), also known as GFRP, is a reinforced plastic made of resin (unsaturated polyester, epoxy resin, phenolic, etc.) as a matrix and fiberglass as a reinforcing material. It is light and hard, non-conductive, stable in performance, high in mechanical strength and corrosion-resistant.

Type of FRP Sheets

Currently TOPOLO-TRUCK provides two types of FRP sheets: thermosetting FRP and thermoplastic FRP (CFRT also called Continuous Fiberglass Reinforced Thermoplastic). These two types of FRP are different resin types and fiberglass types, and they have their own characteristics and applications.

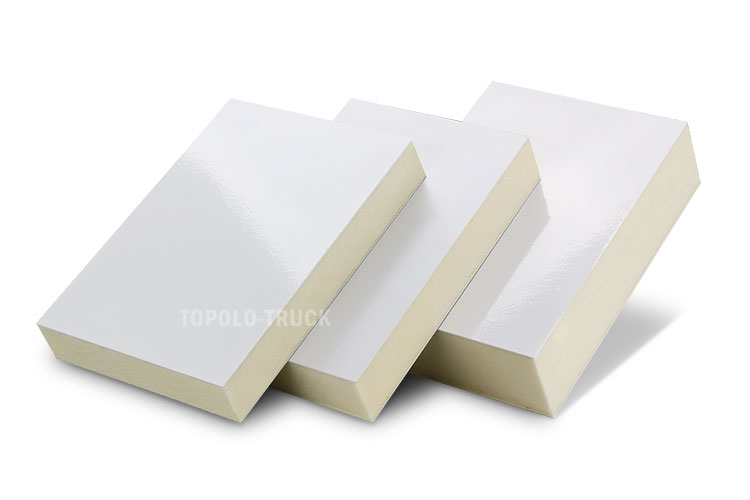

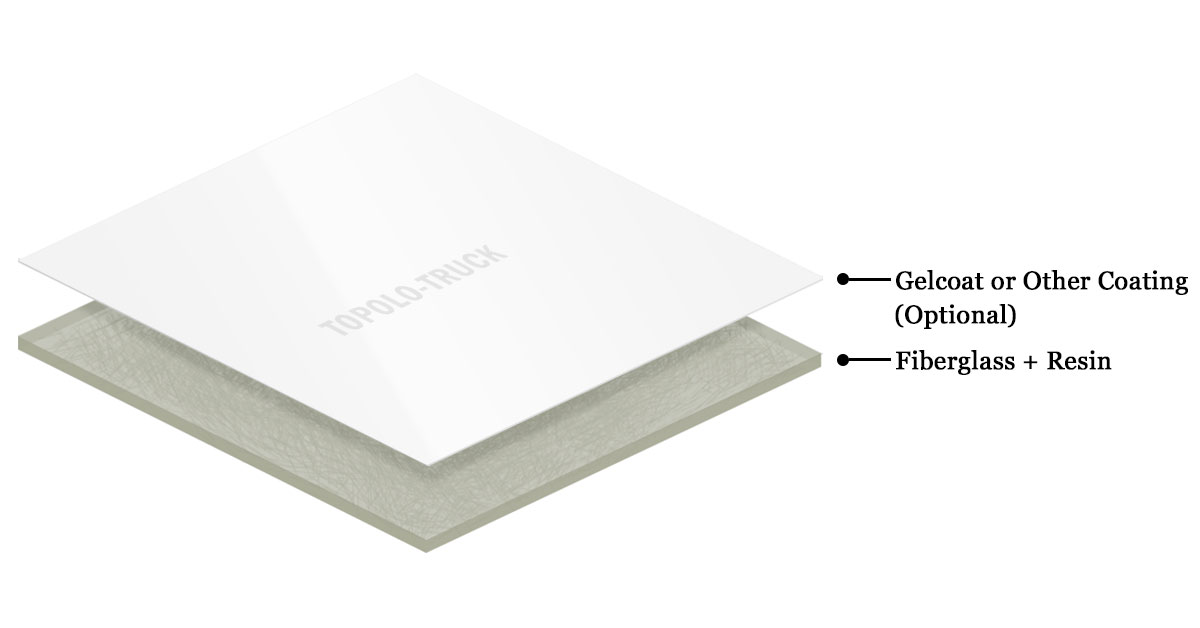

Thermosetting FRP Sheets

- Its fiberglass type is felt or fabric, the surface is a layer of gel coat, and the thermosetting FRP sheet is more flat and smoother.

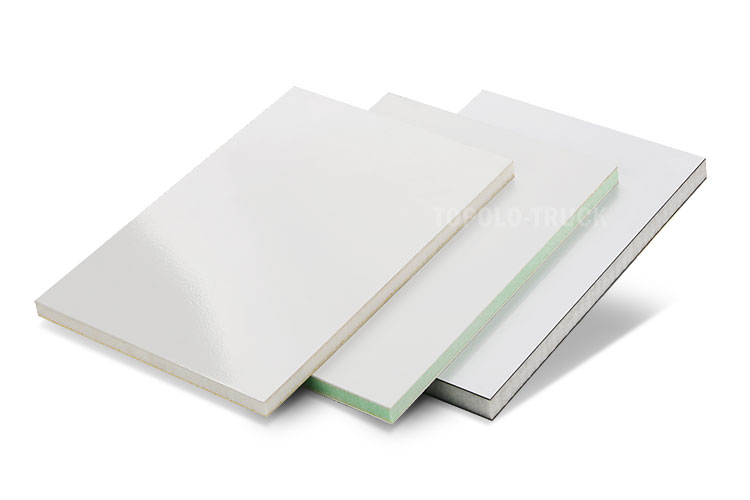

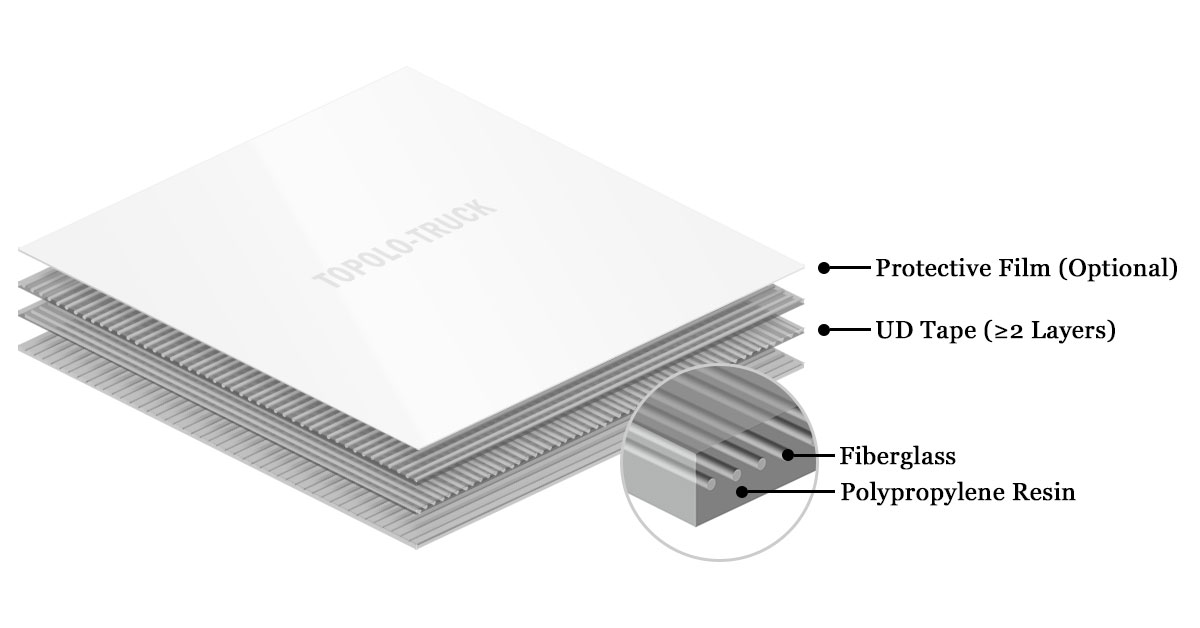

CFRT Sheets

- It is laminated with multiple layers of continuous fiberglass unidirectional prepreg tape, so it is stronger and more resilient, and the sheets can be made thinner.

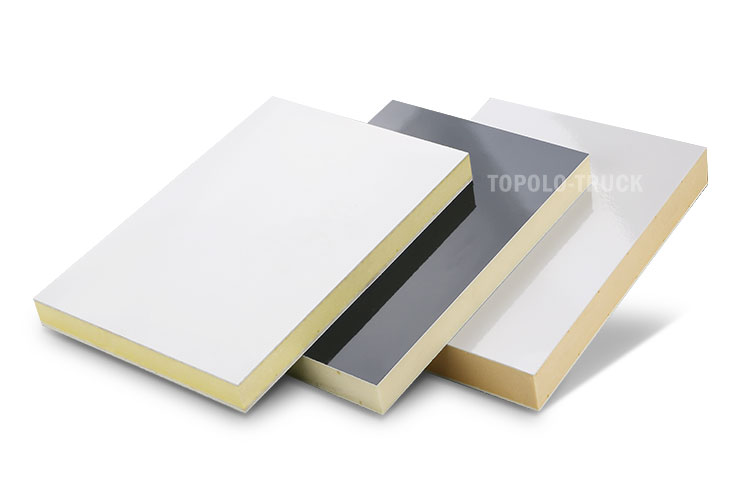

What types of FRP truck panels are there?

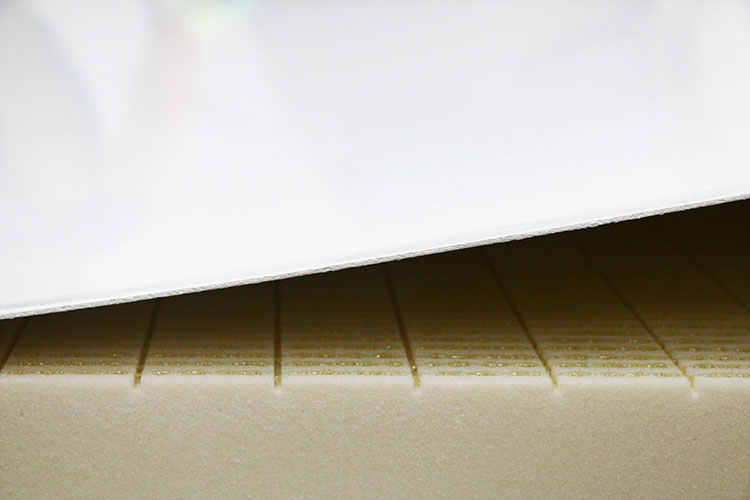

FRP is compatible with various foam (XPS/PU/PET/PVC) and honeycomb (PP) systems, which FRP composite material to choose for the truck body depends on the purpose of the vehicle. For example, glass steel plates with XPS or PU foam cores are usually used to build refrigerated truck boxes, and PVC, PET foam sandwich panels or PP honeycomb core sandwich panels are usually used for dry cargo trucks.

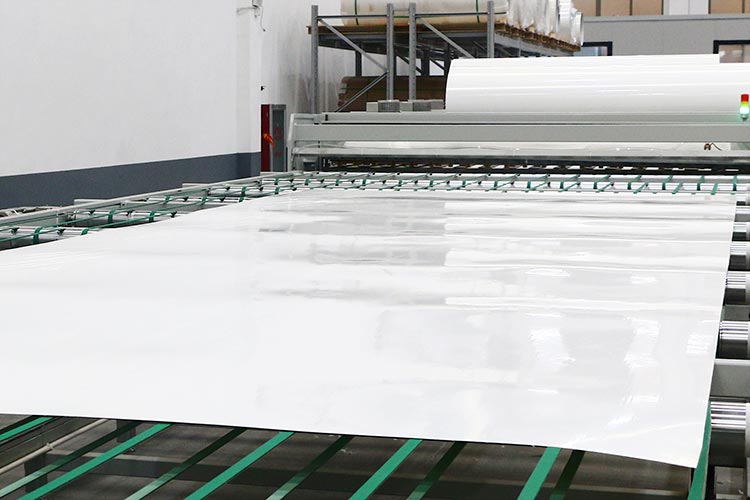

TOPOLO-TRUCK provides high-quality FRP truck panels and provides CNC machining

TOPOLO-TRUCK has many years of manufacturing experience in truck composite panels. We use international advanced production equipment and summarize professional solutions in long-term production practice. We have provided design and manufacturing services for many truck manufacturers around the world.

We Provide:

- Foam core and honeycomb core truck composite panels

- CKD truck unit

- Truck body design solutions

- CAE analysis

Basic Specifications of FRP Truck Panels

- Width: ≤3.2m

- Length: ≤12m

- Thickness: 10~150mm

- FRP Type: Thermosetting FRP, Thermoplastic FRP (CFRT)

- Core material: XPS, PU, PET, PVC foam; PP honeycomb core

- Application: refrigerated trucks, dry cargo trucks.