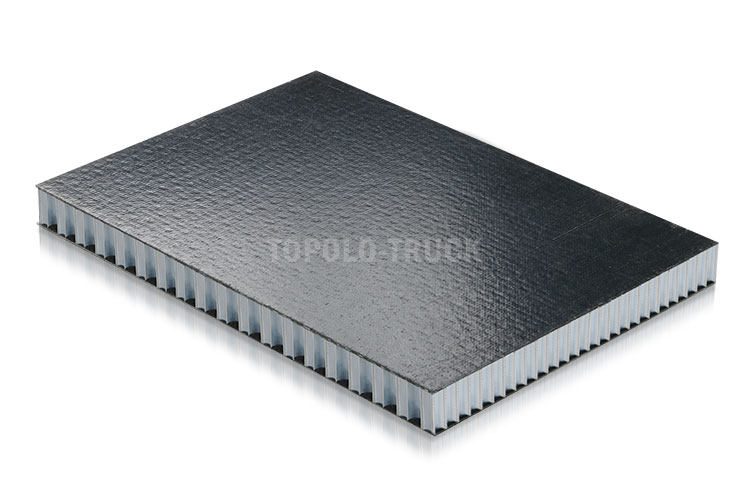

PP Honeycomb Panels for Trailer & Truck Bodies

How to slim down a truck body? Are you still worried about the bulky truck body? The bulky truck body not only reduces transportation efficiency, consumes more raw materials, but also makes your truck chassis overwhelmed. You should choose lighter materials. Fiberglass PP(Polypropylene) honeycomb panel is undoubtedly the representative material of lightweight. It has both lightweight and strength, and is corrosion-resistant. Using it as a truck or trailer box body panel will bring you more economic benefits and safety performance.

PP Honeycomb Core – Achieving Maximum Lightweight

Polypropylene (PP) is a common thermoplastic. Its lightweight, chemical resistance, heat resistance, UV resistance, and low cost make it widely used in many industries, and its recyclability and environmental friendliness also make it an ideal material for sustainable development. Polypropylene honeycomb materials, through their unique honeycomb structure and excellent physical properties, combined with high strength, low density, good impact resistance, and corrosion resistance, provide an ideal solution for lightweight design.

Specification of PP Honeycomb Panels

| omposition | Skin | FRP/GRP: Glass fiber reinforced plastics. |

| CFRT: Continuous fiber reinforced thermoplastic. | ||

| PP Honeycomb Core | Cell size: 8.0, 10, 12 mm. | |

| Density: 60-80kg/m³. | ||

| Compressive Strength: 1.47-1.66MPa. | ||

| Compressive Modulus: 38.9-45.7MPa. | ||

| Shear Modulus(MPa): 0.40-0.45MPa. | ||

| Operating Temperature: -40 – 80℃. | ||

| Panel width | ≤2.8m. | |

| Panel length | ≤12m. | |

| Panel thickness | 5.0~120mm. | |

| Composite methods | Adhesive bonding.(Unsaturated polyester adhesive, polyurethane adhesive, etc) | |

| Thermoplastic lamination. | ||

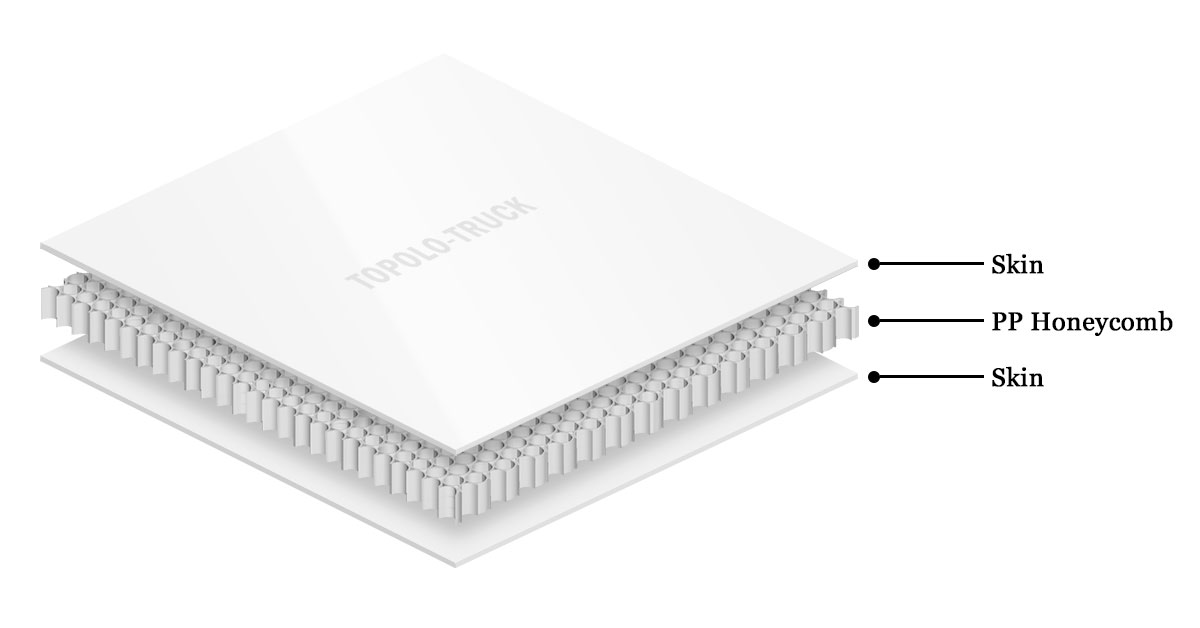

Structure of PP Honeycomb Core Panels

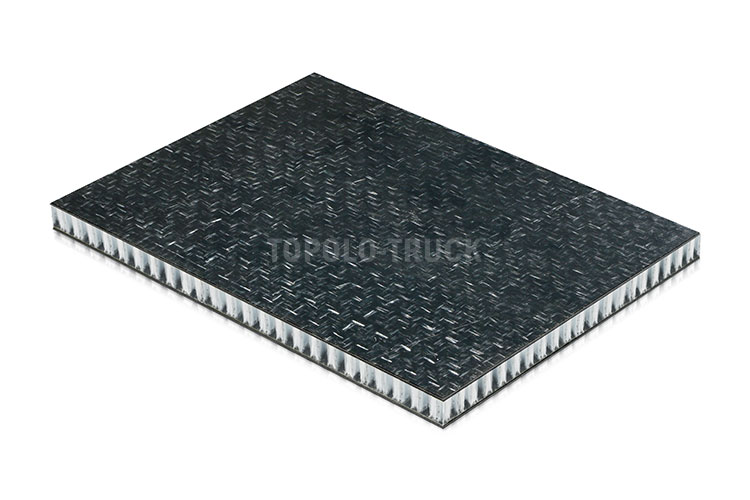

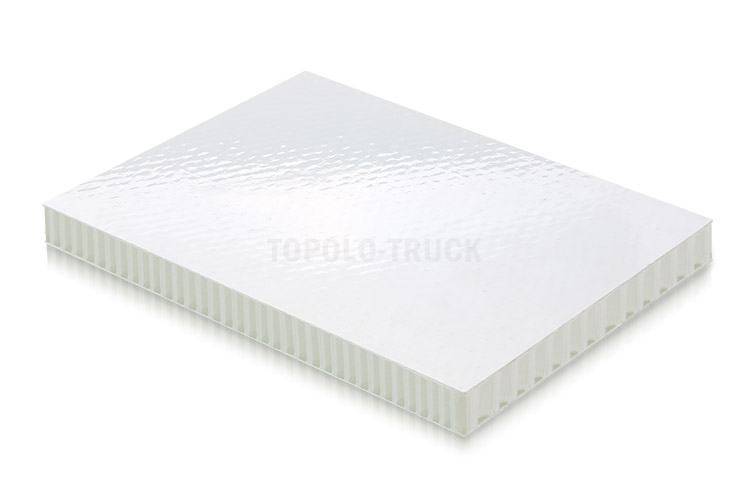

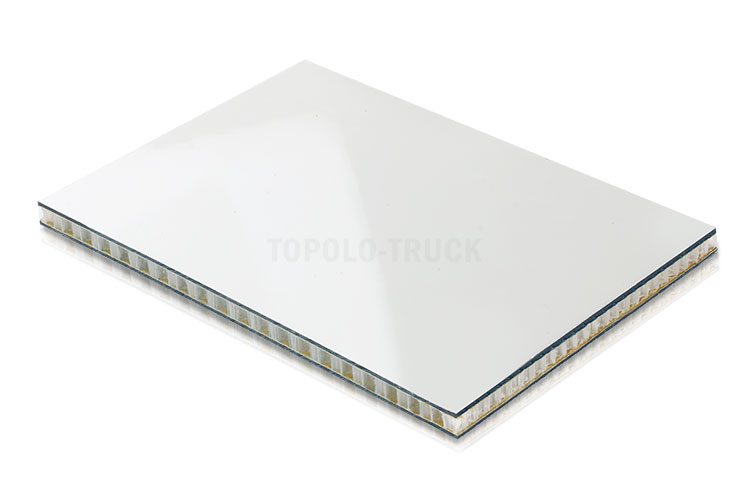

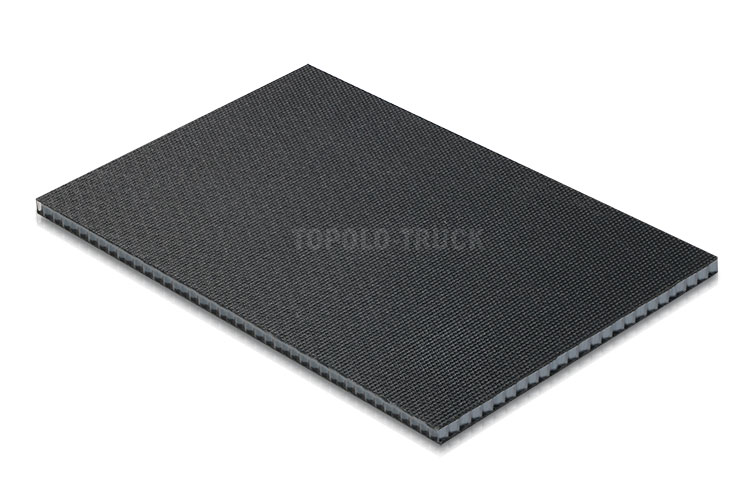

PP honeycomb panel is a three-layer structure composite panel, the middle layer is polypropylene (PP) honeycomb, and the upper and lower layers are fiberglass sheets (FRP/CFRT).

Which Fiberglass Material to Choose as Surface Material

FRP/GRP Sheets

Thermoset FRP (GRP) materials offer higher overall rigidity and surface hardness. Their outer surfaces are typically finished with a high-quality gel coat, resulting in a smooth, flat appearance with a high level of gloss, giving the panels excellent visual appeal. However, the gel coat layer is relatively susceptible to scratches and wear over time. As a result, truck and trailer bodies using FRP skins require more careful and regular maintenance to preserve their appearance and long-term durability.

CFRT Sheets

CFRT sheets, as a new generation of thermoplastic FRP composite materials, offer high strength, lightweight characteristics, outstanding impact resistance, and superior corrosion resistance, providing a highly reliable and stable solution for vehicle body structures. Compared with traditional thermoset FRP, CFRT features greater toughness and higher overall structural rigidity, allowing it to withstand stronger external impacts and demanding operating conditions. However, its surface smoothness and decorative appearance are generally not as refined as those of gel-coated FRP. In addition, CFRT sheets can be efficiently laminated with polypropylene honeycomb cores through a thermoplastic lamination process, forming lightweight, high-strength, and structurally stable sandwich panels.

Our Customized Solutions

TOPOLO-TRUCK’s customized composite panel solutions help your vehicle projects achieve more efficient, safe, and flexible local production, enhancing overall operational efficiency. Customize prefabricated composite panel kits for your vehicle projects to enable localized, fast assembly.

Optimized Panel Structure

Depending on the specific needs of the vehicle, we use various composite materials to provide higher strength, durability, and lightweight designs. Whether it’s FRP, aluminum alloy, or other composite materials, we tailor the panels to ensure maximum performance and reliability.

High-Precision CNC Processing

Utilizing high-precision CNC machining, we ensure that every panel meets strict size and tolerance requirements.

Obtain PP Honeycomb Sandwich Panel Samples

We offer customized PP honeycomb sandwich panel samples based on your provided materials or specific requirements for testing purposes.