PU Foam Sandwich Panels for Trailer & Truck Bodies

To ensure excellent insulation performance for refrigerated truck and trailer bodies, selecting the right insulation material is crucial. Among various materials, composite panels with PU (Polyurethane) foam as the core material are the ideal choice.

Polyurethane Foam – Thermal Insulation & Lightweight

PU foam has an extremely low thermal conductivity, effectively blocking external heat and ensuring a stable internal temperature, thereby improving energy efficiency and reducing energy loss. Additionally, the lightweight and high-strength characteristics of PU foam allow for effective weight control of the vehicle body without compromising structural strength and durability. Its moisture resistance also ensures that refrigerated trucks maintain insulation performance even in humid environments, adapting to harsh transportation conditions. Therefore, using PU foam composite panels as insulation material for refrigerated trucks and trailers significantly enhances the efficiency and reliability of cold chain transportation.

Specification of PU Foam Sandwich Panels

| Composition | Skin | FRP/GRP: Glass fiber reinforced plastics. |

| CFRT: Continuous fiber reinforced thermoplastic . | ||

| Aluminum alloy. | ||

| Coated Steel. (GI, GL, PPGI, PPGL) | ||

| Polyurethane Foam Core | Density: 28-50kg/m³. | |

| Thermal Conductivity: ≤0.0270W/(m·K) | ||

| Compression Strength: ≥200kPa | ||

| Water Absorption: ≤3.0% | ||

| Fire Growth Rate(FIGRA 0.4MJ): ≤750W/s | ||

| Smoke Growth RateSMOGRA (s3): >180 m²/s² | ||

| Flame Retardant Grade: B1. | ||

| Operating Temperature Range: -50°C to +75°C. | ||

| Panel width | ≤3.2m. | |

| Panel length | ≤13m. | |

| Panel thickness | 20~150mm. | |

| Composite methods | Adhesive bonding.(Unsaturated polyester adhesive, polyurethane adhesive, etc) | |

| Added materials | Aluminum profiles, steel profiles, fiberglass profiles, wood, plywood, high-density PVC, high-density PU, etc. | |

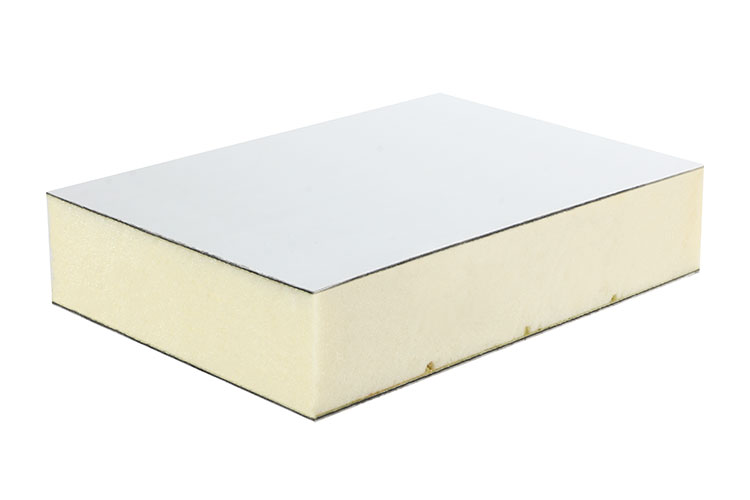

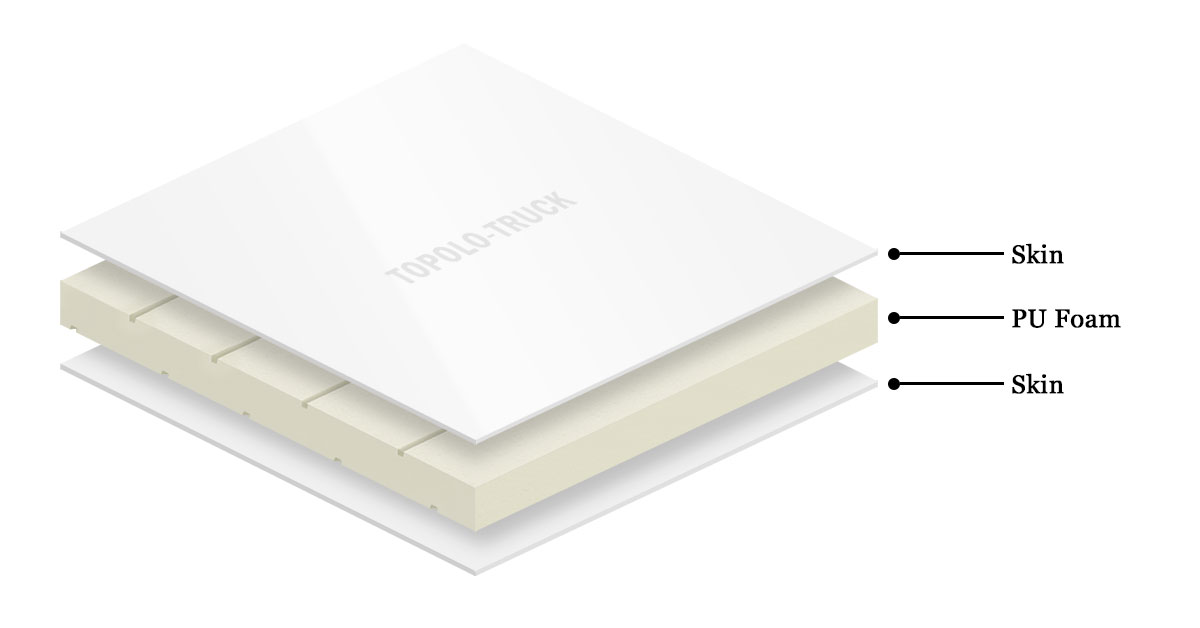

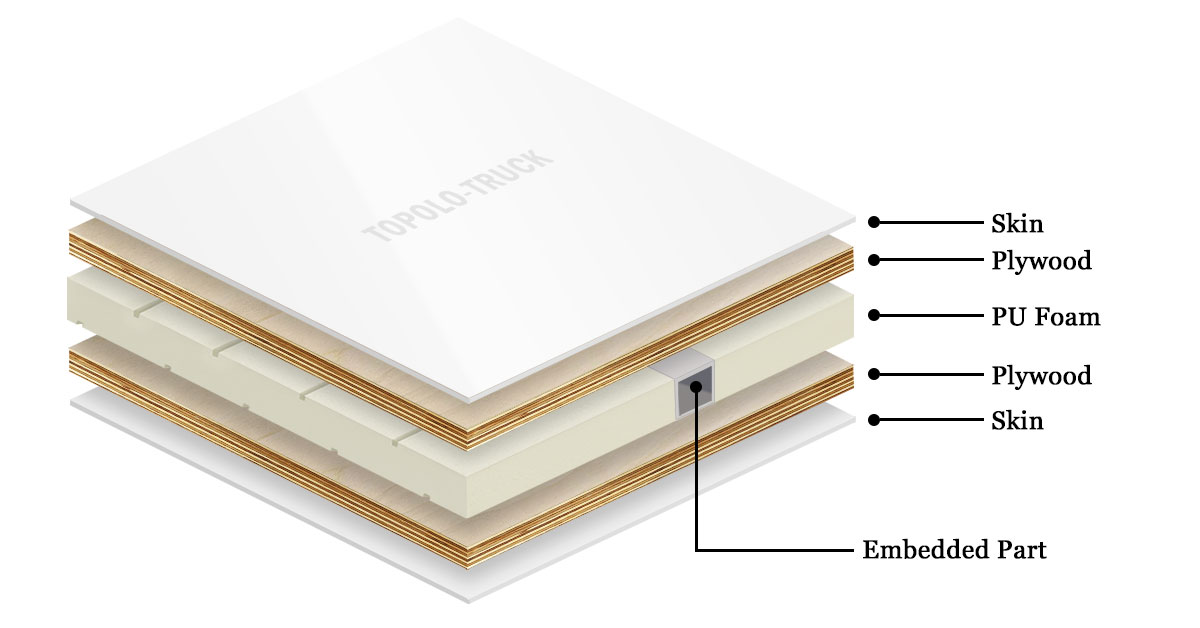

Structure of PU Foam Core Sandwich Panels

We design and engineer unique composite panel structures, carefully tailored to meet your specific requirements and ensure optimal performance. Whether it’s for enhancing insulation, structural strength, or aesthetic appeal, our custom solutions are crafted to address your unique needs, ensuring durability, efficiency, and long-term value.

Standard Structure

- Features: A typical three-layer sandwich structure with inner and outer skins and a polyurethane foam core.

- Applications: Side panels, front panels, rear panels.

Reinforced Structure

- Features: A structural layer of plywood or other materials is added inside the sandwich panel, while materials such as wood, fiberglass profiles, and metal profiles are embedded to enhance the structural strength of the composite panel.

- Applications: Floor panels, roof panels.

Skin Materials

FRP/GRP Sheets

FRP sheets are an ideal material for truck and trailer bodies due to their lightweight, high strength, corrosion resistance, good thermal insulation, and weather resistance, making them widely used in various transportation vehicles such as refrigerated trucks and dry cargo trucks. They not only effectively reduce vehicle weight and improve transportation efficiency, but also possess UV resistance, impact resistance, and low maintenance costs, ensuring long-term vehicle stability in harsh environments. Furthermore, the excellent mechanical properties and aesthetically pleasing design of FRP sheets make them an essential component of various commercial vehicles.

CFRT Sheets

CFRT sheets, as a new type of thermoplastic FRP material, offer highly reliable vehicle body solutions thanks to their advantages such as high strength, lightweight, high temperature resistance, impact resistance, and corrosion resistance. Whether for refrigerated trucks, dry cargo trucks, or special-purpose vehicles, CFRT sheets can improve vehicle safety, durability, and transportation efficiency, while reducing maintenance costs and extending vehicle lifespan.

Aluminum Alloy Sheets

Using aluminum alloy sheets for truck and trailer bodies provides numerous advantages, including a lightweight structure, high strength-to-weight ratio, corrosion resistance, and low maintenance. These benefits lead to improved fuel efficiency, increased payload capacity, and lower operational costs. Additionally, aluminum’s recyclability and ability to withstand extreme conditions make it an environmentally friendly and durable option for commercial vehicle manufacturers.

Coated Steel Sheets

Coated steel sheets offer a highly durable, cost-effective, and versatile body solution. They combine high strength, corrosion resistance, and aesthetic appeal, while providing long-term protection against environmental and mechanical stresses.

Our Customized Solutions

TOPOLO-TRUCK’s customized composite panel solutions help your vehicle projects achieve more efficient, safe, and flexible local production, enhancing overall operational efficiency. Customize prefabricated composite panel kits for your vehicle projects to enable localized, fast assembly.

Optimized Panel Structure

Depending on the specific needs of the vehicle, we use various composite materials to provide higher strength, durability, and lightweight designs. Whether it’s FRP, aluminum alloy, or other composite materials, we tailor the panels to ensure maximum performance and reliability.

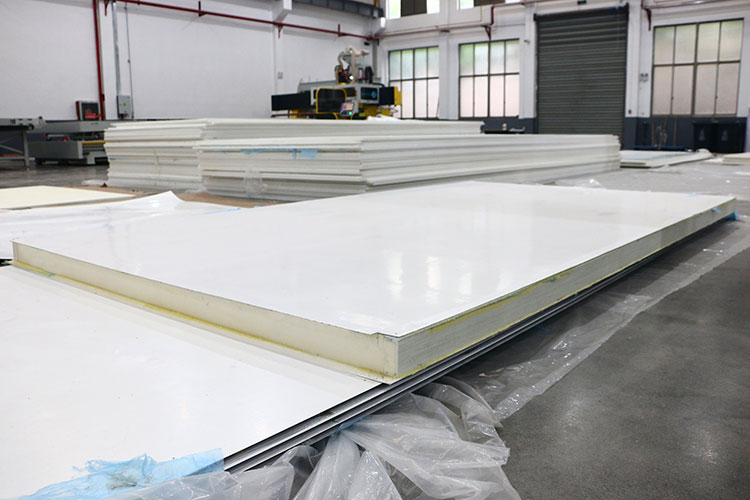

High-Precision CNC Processing

Utilizing high-precision CNC machining, we ensure that every panel meets strict size and tolerance requirements.

Obtain PU Foam Sandwich Panel Samples

We offer customized PU foam sandwich panel samples based on your provided materials or specific requirements for testing purposes.