Composite Flooring

Revolutionizing Camping Trailer Construction

The advent of integrated composite flooring has brought a revolutionary breakthrough to the construction of off-road camper trailers. Whether it’s for standardized mass production or personalized DIY modifications, this innovative structure significantly simplifies the construction process while achieving an overall enhancement in trailer performance. This advantage is particularly evident when the trailer is driven on bumpy, rugged unpaved roads—despite long-term exposure to intense vibrations and irregular forces, the flooring structure maintains excellent flatness and structural stability, providing a solid and reliable foundation for the trailer’s internal facilities.

What is Integrated Composite Flooring?

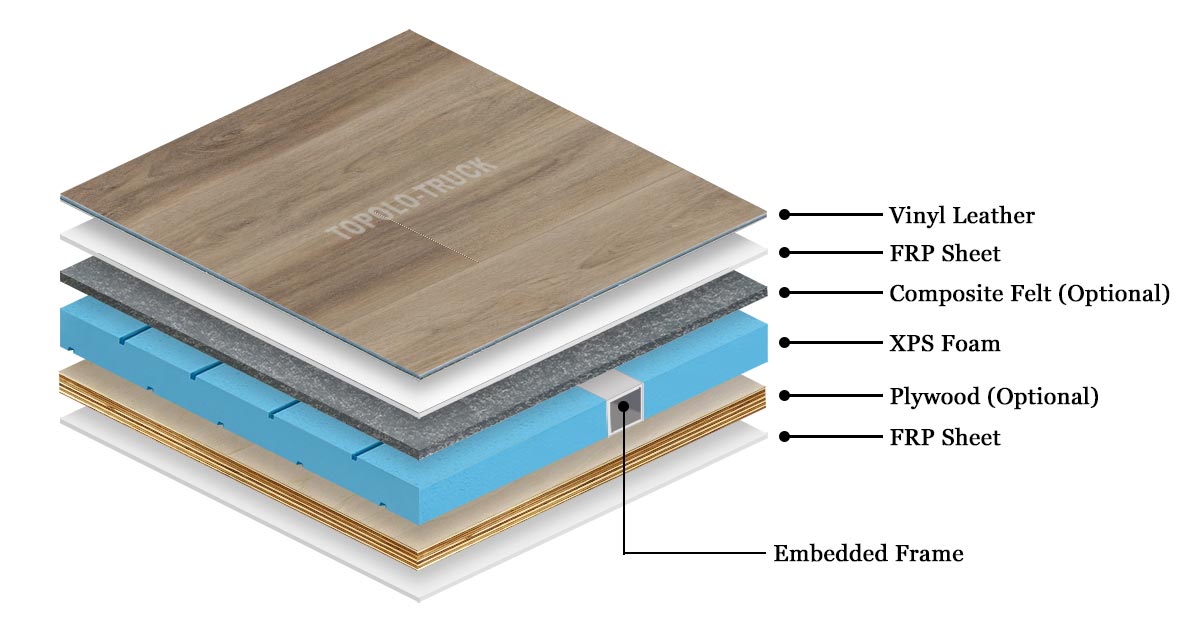

Integrated composite flooring is an integrated load-bearing part made from a multi-layer sandwich structure. It consists of several functional layers, including an insulation layer, a waterproof layer, an optional reinforced layer, an embedded frame, and a decorative surface layer.

These functional layers are tightly bonded using high-performance, eco-friendly adhesives and undergo composite curing in a professional press. Afterward, the flooring is sent to high-precision CNC machines for integrated fine processing. The finished integrated composite flooring is pre-designed with standardized interfaces, such as tire mounting locations, water pipe channels, electrical conduit pathways, and other installation points. Users do not need to perform additional cutting or drilling on-site. It can be directly lifted and fixed onto the trailer chassis, significantly reducing construction time.

Standard Load-bearing Structure

Heavy Load-bearing Structure

Core Functional Layer Analysis

Insulation Layer

- XPS Foam

Made of low thermal conductivity XPS (extruded polystyrene) foam with customized thickness design, achieving a thermal conductivity as low as 0.027 W/(m·K). Its closed-cell honeycomb structure effectively blocks the heat transfer path, providing excellent thermal insulation whether in cold environments to prevent heat loss to the ground, or in hot weather to block the intrusion of high ground temperatures into the trailer, maintaining a comfortable internal temperature.

Waterproof Layer

- FRP Sheet

A high-strength FRP (fiber-reinforced plastic) panel is used as the core waterproof barrier. The dense resin matrix and fiber-reinforced structure completely prevent the infiltration of water vapor from rain, dew, and ground moisture into the core material, avoiding issues such as rot, deformation, or reduced thermal insulation performance caused by moisture, significantly enhancing the durability of the flooring.

Reinforced Layer (Optional)

- Waterproof Plywood & Composite Felt

Based on load-bearing requirements, optional materials such as waterproof plywood or LWRT (lightweight reinforced thermoplastic) felt can be chosen. These materials are characterized by high modulus and bend-resistance properties, significantly improving the load-bearing capacity of the composite flooring, making it suitable for heavy equipment mounting, multi-person habitation, and other high-intensity usage scenarios.

Embedded Frame

- Aluminum Profiles, Timber, etc.

The lightweight, aluminum tubes or corrosion-treated hardwood (timbers) frame is pre-fabricated and embedded directly into the core material during the composite molding process. The grid or truss design of the frame greatly enhances the structural strength and deformation resistance of the flooring, ensuring stability under heavy loads and rough conditions.

Decorative Surface Layer

- Vinyl Leather

Made from environmentally-friendly vinyl flooring, the surface replicates the texture and feel of natural wood. It offers a smooth, comfortable touch and supports direct skin contact. Additionally, it features anti-slip, wear-resistant, and easy-to-clean properties, capable of withstanding frequent friction from outdoor footwear and water splashes, balancing both practicality and aesthetics.

Key Advantages of Integrated Composite Flooring

- Lightweight Advantage

Compared to traditional steel or solid wood flooring, integrated composite flooring reduces weight by 30%-50% while maintaining the same load-bearing capacity. The lightweight structure effectively lowers the overall weight of the trailer.

- High Load-Bearing Performance

The standard composite flooring can support a uniformly distributed load of over 300kg/m², while heavy-duty customized versions can exceed 500kg/m². This is sufficient to carry camping gear, living supplies, and even small off-road motorcycles, meeting diverse outdoor usage needs.

- Excellent Thermal Insulation

The low thermal conductivity of the XPS insulation layer, combined with the sealed structure of the FRP waterproof layer, creates an efficient thermal insulation barrier.

- Comprehensive Waterproofing and Moisture Resistance

Even during rainy season camping or after driving through water, the flooring interior remains free from water accumulation or moisture, effectively addressing the common issues of mold and rot found in traditional flooring. This greatly extends the flooring’s lifespan.

- Reliable Electrical Insulation

Both the core material (XPS foam) and the FRP panel of the composite flooring are excellent electrical insulators. This feature effectively prevents safety hazards such as electric leakage or short circuits during electrical installation.