FRP Sheets for Trailer & Truck Bodies

What is flat FRP sheet?

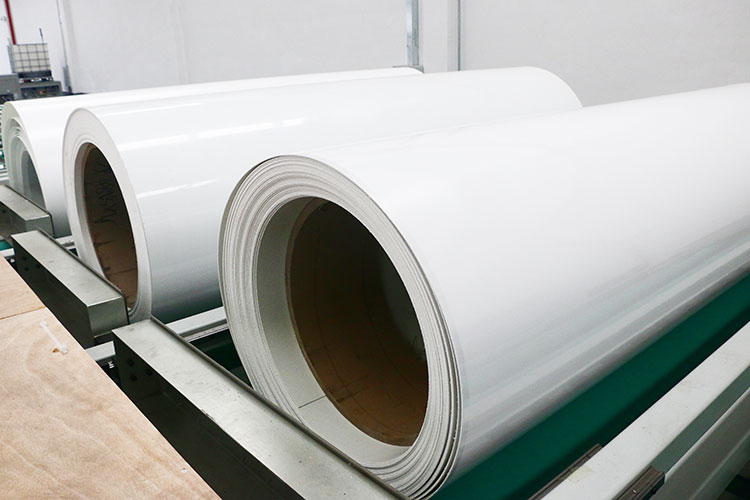

Flat FRP (Fiberglass Reinforced Plastic also called GRP) sheet is a material made from a combination of glass fibers and resins, often using thermoset polyurethane resin. These sheets are widely used for manufacturing trailer and truck bodies due to their durability and specific material properties. These sheets are usually available in rolls and are cut into sheets of the required length when used.

FRP Features

☑ Lightweight

FRP sheets are significantly lighter than traditional metal sheets, contributing to improved fuel and battery efficiency and ease of handling.

☑ Waterproof

Waterproof and moisture-proof, preventing rust and moisture damage.

☑ Corrosion-resistant

FRP sheets have excellent corrosion resistance, resisting erosion from a variety of chemicals and environmental factors.

☑ Thermal Insulation

Provides good thermal insulation, helping to maintain indoor temperature in cold or hot environments.

Sizes

- Thickness: 0.7-5.0mm.

- Width: Maximum 3.2m.

- Length: 100-250m/roll.

- Roll Diameter: 750-800mm.

- Roll Core Siameter: 500~520mm.

TOPOLO-TRUCK offers FRP sheets for your truck and trailer bodies in various sizes, thicknesses, colors, and surface treats. Whether it’s enhancing structural strength, durability, or improving aesthetic appearance, we deliver high-quality FRP sheets that ensure your vehicles not only perform at their best but also look great.

Performance Parameters

| Performance Item | Unit | Reference Value | Certification Standard |

| Density | g/cm³ | 1.38 – 1.50 | GB/T1463 – 2005, ASTM D 792 |

| Barcol Hardness | Hbr | 30 – 60 | GB/T3857 – 87, ASTM D 2583 |

| Bending Strength | Mpa | 120 – 180 | GB/T1449 – 2005, ASTM D 790 |

| Bending Modulus | Mpa | 39 – 50 | GB/T1449 – 2005, ASTM D 790 |

| Charpy Impact Strength | KJ/m² | 30 – 50 | GB/T1449 – 2005, ASTM D 256 |

| Thermal Conductivity Coefficient | 10⁻⁵/°C | 0.15 – 0.32 | GB/T3139 – 2005, ASTM D 5470 |

| Wear Resistance Coefficient | mg/min | 4 | GB/T1689 – 2014, ASTM G115 |

| Temperature Range | °C | -40 – +120 | – |

| Water Absorption Rate | % | < 0.2 | – |

Thickness and Performance

| Item | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight (Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content (%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength (Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break (%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus (Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength (KJ/m2) | 45 | 55 | 70 | 80 | 95 |

FRP Sheet Surface Treatment and Applications

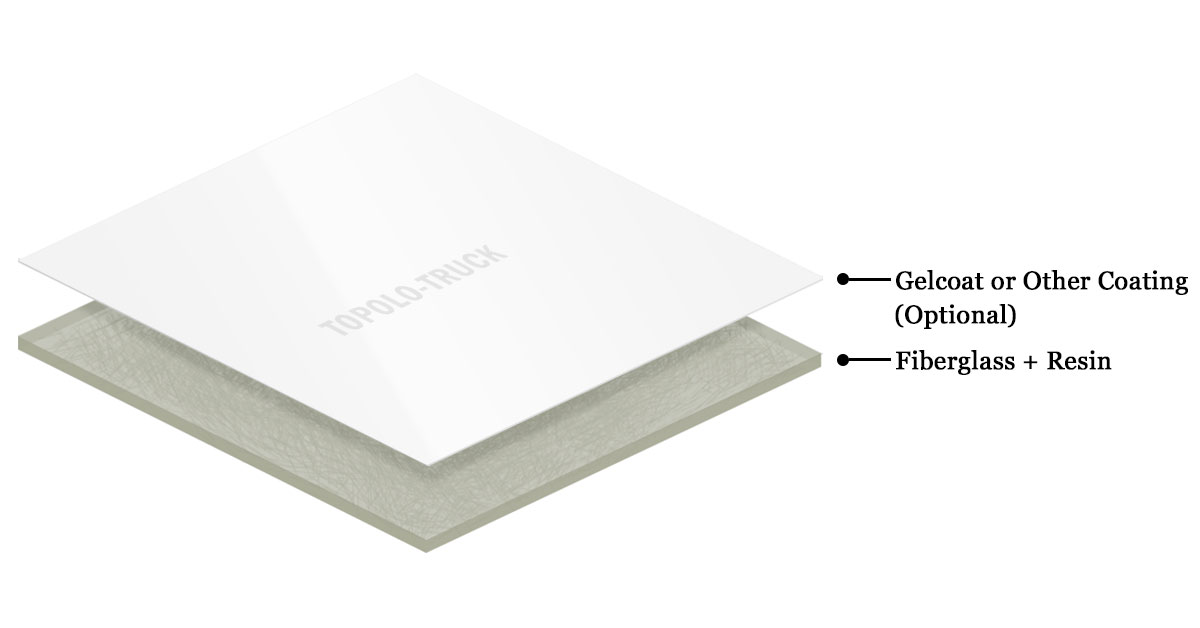

Uncoated FRP Sheets

- Features: Primarily composed of glass fiber and resin, semi-transparent.

- Applications: Commonly used for dry cargo trailer roofs and as a reinforcing layer (not exposed) in composite panels.

Flat Gel Coating FRP Sheets

- Features: Smooth and flat, available in matte or glossy finishes. Available in a variety of colors, including RAL and Pantone color charts.

- Applications: Wall panels, ceiling panels, partitions, flooring. Suitable for extreme sunlight and high-salinity environments, such as marine climates.

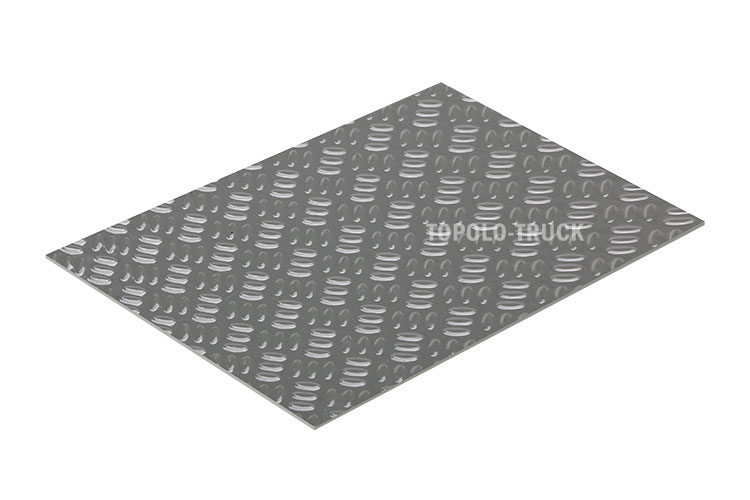

Embossed Gelcoat Coated FRP Sheets.

- Features: Gelcoat coating with embossed textures such as bubbles and granules, providing excellent decorative effects.

- Applications: Flooring, wall panels.

Quartz Sand Coated FRP Sheets

- Features: The surface of the FRP sheet is coated with a layer of quartz sand. Mimics the appearance of natural rock, offering excellent slip resistance and wear resistance.

- Applications: Flooring.

Fiber Types of FRP Sheets

The performance of FRP sheets is greatly influenced by the type of fiberglass used and its weaving pattern. Different fiber types and weaving methods not only affect the mechanical properties such as strength, toughness, and tensile strength but also determine how the FRP sheets perform in different environments and applications.

Chopped Fiberglass Mat

Chopped fiberglass mat is made of randomly distributed short fibers, typically ranging from a few millimeters to a few centimeters in length. The random arrangement of fibers provides consistent physical properties, making it suitable for applications requiring uniform mechanical performance.

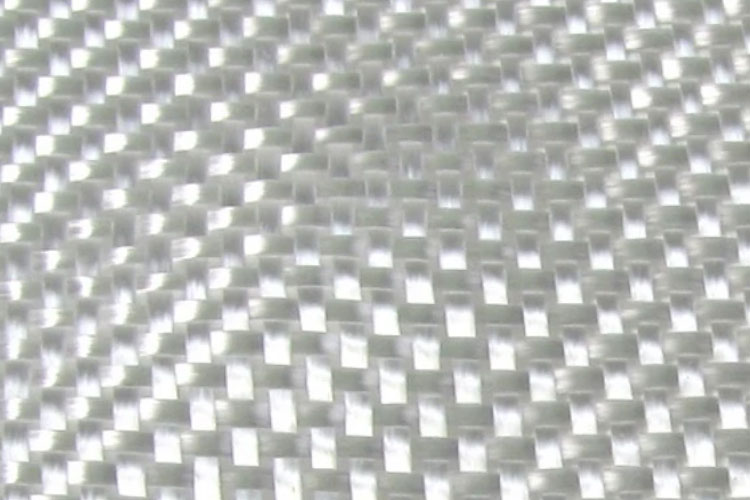

Woven Fiberglass Fabric

Woven fiberglass fabric is composed of long fibers arranged in a directional weave, typically with warp and weft threads interlaced to form a regular grid structure. Due to its directional fiber layout, woven fiberglass fabric offers greater structural stability, making it ideal for applications under complex stress conditions.

Application Cases of FRP Sheets

Refrigerated Trucks/Trailers

FRP sheets are widely used in refrigerated trucks and trailers, their excellent thermal insulation helps maintain the low internal temperature, ensuring the freshness and efficient transport of goods.

Dry Cargo Trucks/Trailers

The lightweight and durability of FRP sheets make them an ideal choice for these vehicles, able to withstand various environmental factors while maintaining the integrity of the truck body.

Ambulance Trucks/Trailers

Ambulance trucks and trailers need to have high strength, durability, and ease of cleaning. FRP sheets provide a lightweight and sturdy outer shell, making them ideal for the fast mobility needs of ambulances.

Expedition Trucks/Trailers

Expedition trucks and trailers are typically used for long-distance travel and tasks in extreme environments. The weather resistance, UV protection, and corrosion resistance offered by FRP sheets make them an ideal choice for the construction of expedition vehicle bodies under harsh conditions.

Day-Old Chick Transport Trucks/Trailers

Day-old chick transport vehicles need to maintain a constant temperature and hygienic environment to ensure the health of the chicks during transport. FRP sheets provide effective temperature control and an easy-to-clean surface in these trucks.

Food Truck/Trailers

Food trucks/trailers require high durability, hygiene, and structural strength. FRP sheets have smooth surfaces that are easy to clean and durable, making them ideal for securing and protecting kitchen equipment and facilities.