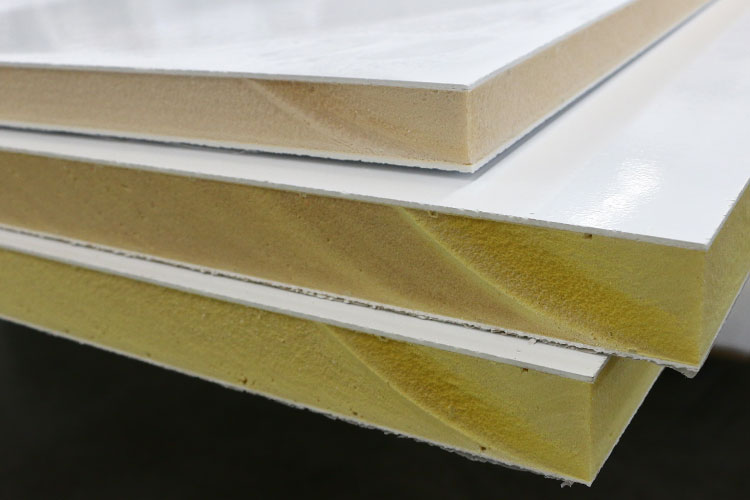

XPS foam core sandwich panels are one of the most popular truck body panel materials. Commonly used skin materials include FRP, aluminum, pre-painted galvanized steel, stainless steel, etc., among which FRP is the most commonly used skin material. The most notable feature of XPS sandwich panels is that XPS foam has the advantages of lightweight, non-absorbent, thermal conductivity, etc., especially in refrigerated trucks, these advantages have been fully utilized.

Specifications

| Skin Material | FRP Sheet, CFRT Sheet, Aluminum Sheet, Plywood, Stainless Steel, Aluzinc Steel, etc |

| Core Material | XPS(extruded polystyrene) Foam Board |

| Width | ≤3.2m |

| Total Thickness | 10~120mm |

| Length | ≤12m |

| Core Density | 30~50kg/m³ |

| Skin Color | RAL Color Series |

| Processing | CNC Machining, Embedded Structure |

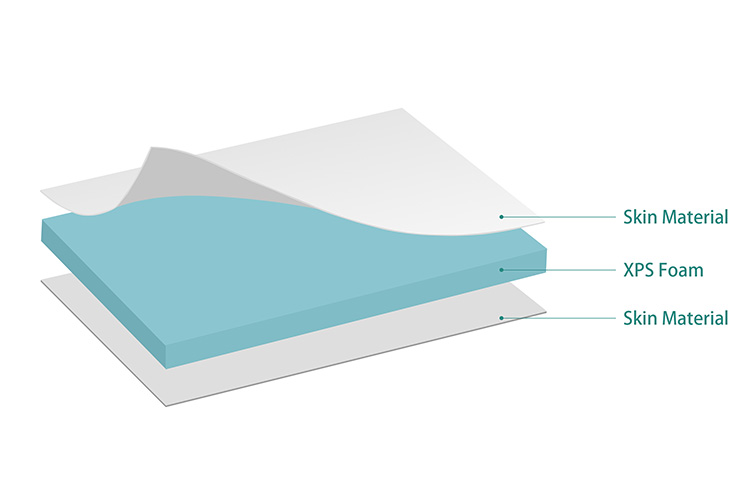

Structure of XPS Foam Core Sandwich Panels

FRP Skin XPS Foam Sandwich Panels

FRP Skin XPS Foam composite panels will not be brittle at ultra-low temperatures, will not deform at high temperatures, and can prevent heat transfer. They are more lightweight and more waterproof than metal or wooden skin sandwich panels.

Our Service

TOPOLO-TRUCK provides a series of XPS composite panel solutions for box truck manufacturers, including design, manufacturing, CNC processing,