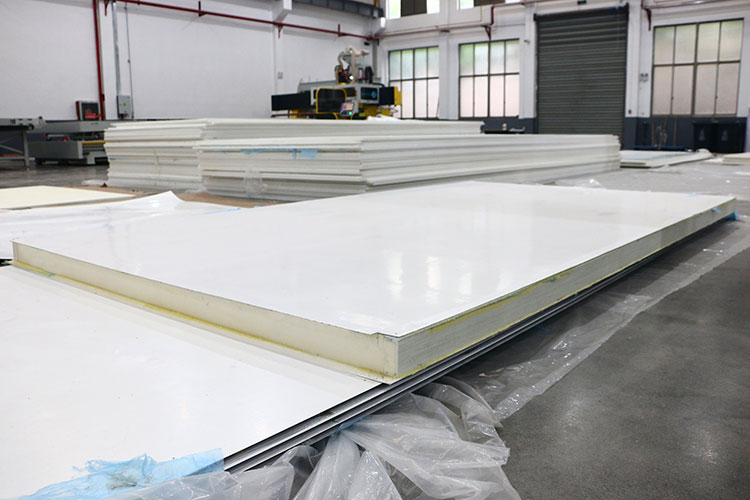

PU (polyurethane) foam core sandwich panel is the most common material for refrigerated truck bodies. The PU foam board used for truck bodies has a rigid closed-cell structure. The extremely low thermal conductivity of PU foam endows it with excellent thermal insulation performance. This is unmatched by other foam core materials.

Specifications of PU Sandwich Panels

| Width | ≤3.2m |

| Thickness | 10~150mm |

| Length | ≤12m |

| Core Density | 45~80kg/m³ |

| Skin | FRP, CFRT, Aluminum, Stainless Steel, Prepainted Steel |

| Processing | CNC Machining, Embedded Structure |

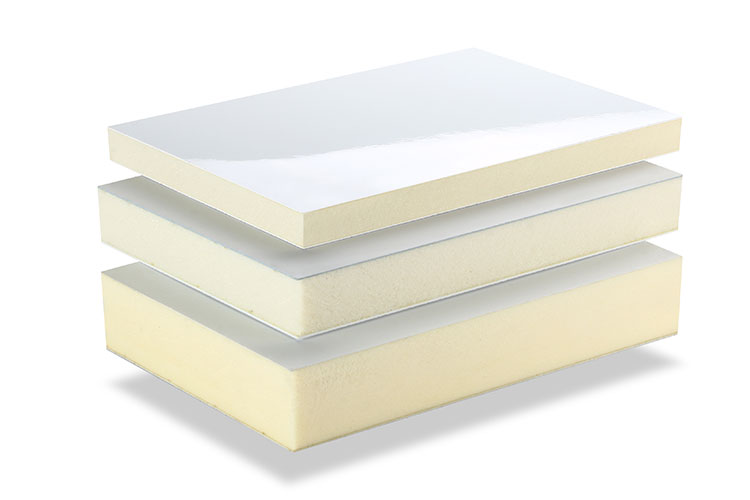

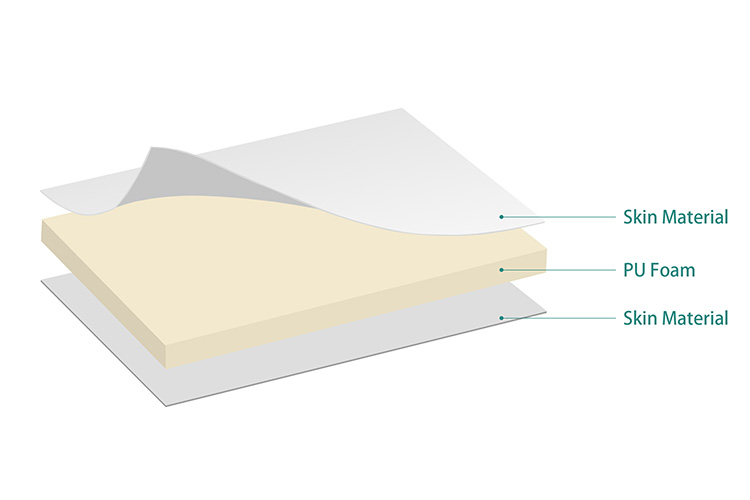

Structure of PU Foam Core Sandwich Panels

Performance of PU foam board (for reference only)

| Detection parameters | Unit | Reference |

| Core Density | kg/m3 | 45-80 |

| Dimension Stability | % | ≤1.5 |

| Thermal Conductivity | W/(m·K) | ≤0.0270 |

| Compression Strength | kPa | ≥200 |

| Water Absorption | % | ≤3.0 |

| Fire Growth Rate(FIGRA 0.4MJ) | W/s | ≤750 |

| Smoke Growth RateSMOGRA (s3) | m2/s2 | >180 |

| 600s Total Smoke ProductionTSP600s (s3) | m2 | >200 |

| 600s Burning droplets/ particles Duration(d0) | s | 0 |

| 60s Flame Tip Height Fs | mm | ≤150 |

| Burning drips igniting filter paper within 60s | — | No ignition |

| Oxygen Index | % | ≥26 |

FRP Skin PU Foam Sandwich Panels

The two sides of the FRP skin PU foam sandwich panel are gel-coated FRP, and the FRP skin and PU foam core are bonded together with PU glue, which effectively prevents problems such as delamination and bulging. In order to enhance the strength of the composite panel, reinforcement structures such as aluminum tubes, stainless steel tubes, glass steel tubes, timbers, etc. are usually embedded inside.