Refrigerated Cargo Trailer

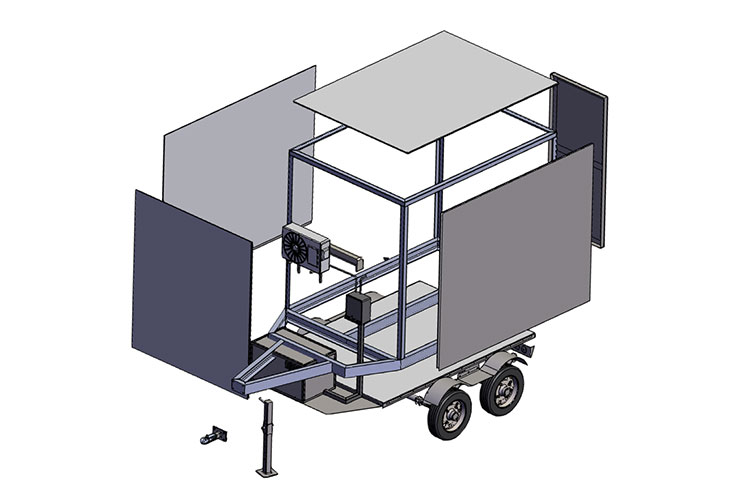

The refrigerated cargo trailer is a critical component in the cold chain logistics sector. It is designed to transport perishable goods at specific temperatures, ensuring that items such as food, pharmaceuticals, and other temperature-sensitive products remain in optimal condition during transit.

Body Desgin

| Type | Length | Width | Height |

| Standard Refrigerated Trailer | 48 ft (14.6 m) to 53 ft (16.2 m) | 8.5 ft (2.6 m) | 9.5 ft (2.9 m) |

| Medium Refrigerated Trailer | 28 ft (8.5 m) to 45 ft (13.7 m) | 8.5 ft (2.6 m) | 9.5 ft (2.9 m) |

| Small Refrigerated Trailer | Length: 16 ft (4.9 m) to 24 ft (7.3 m) | 8 ft (2.4 m) | 8.5 ft (2.6 m) |

Product Features

- Optimized design.

- Quick assembly.

- Thermal insulation.

- Durable.

- Waterproof and moisture-proof.

- Reduce manufacturing costs.

Expert in CKD refrigerated truck body solutions

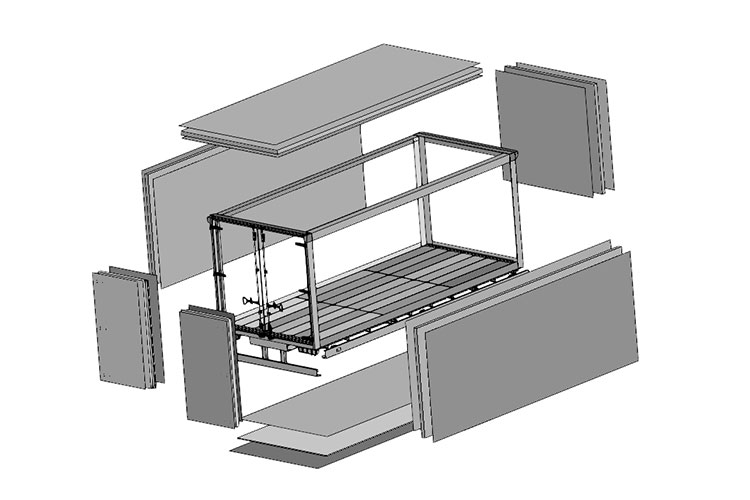

CKD (complete knock-down) refrigerated truck bodies refer to a manufacturing process where they are completely disassembled into parts, then packed and transported to another location for reassembly. This process can reduce transportation and manufacturing costs and promote local employment.

TOPOLO-TRUCK – Truck & Trailer Box Body Manufacturer

We offer customized solutions for the following projects

☑ Box Body Design

Design the structure of truck and trailer box bodies according to customer requirements, ensuring functionality and safety standards are met.

☑ Box Body Structural Panel Production

Provide high-quality structural panels for box bodies, including foam sandwich panels, honeycomb sandwich panels, plywood sandwich panels, etc., to meet the needs of various types of box bodies.

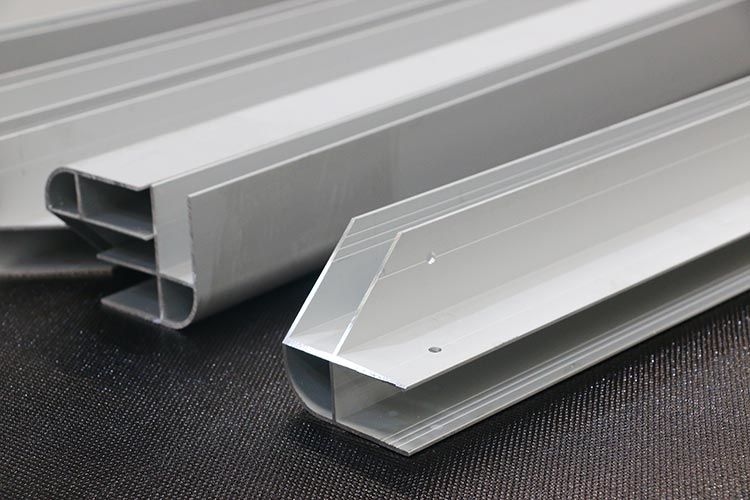

☑ Box Body Accessories Supply

Supply various accessories needed for box bodies, including doors, windows, sub-frames, hinges, aluminum alloy frames, sealing strips, etc., ensuring the integrity and functionality of the entire vehicle structure.

☑ Box Body Assembly

Provide complete box body assembly services, ensuring efficient and precise integration of all components into a high-quality finished product.

Box Body Assembly Types

☑ CKD (Completely Knocked Down) Box Body

A CKD box body refers to all the box body components being fully disassembled and shipped to the customer’s location for on-site assembly via sea, air, or other means. This approach is suitable for international markets, especially when customers need to reduce transportation costs or have the capability to assemble locally. The advantages of CKD box bodies include reduced shipping costs, greater flexibility, and easier customization.

☑ SKD (Semi Knocked Down) Box Body

An SKD box body involves pre-assembling the main structural parts (such as the frame, panels, etc.) while shipping separate smaller components (like doors, windows, and accessories). Upon receiving the parts, the customer only needs to assemble some of the details. This option is ideal for customers with some assembly capabilities who need to reduce on-site assembly work. SKD box bodies offer lower transportation costs and a faster delivery cycle.

☑ CBU (Completely Built Up) Box Body

A CBU box body refers to a fully assembled box body, where all parts are assembled at the factory and delivered as a complete unit. This approach is suited for customers who need quick delivery, as it eliminates the need for on-site assembly and ensures consistent quality and precision. The advantages of CBU box bodies include a shorter delivery cycle and higher assembly accuracy, but the shipping costs are higher.

Reasons to Choose TOPOLO-TRUCK

TOPOLO-TRUCK, as a manufacturer, has a comprehensive and advanced production facility and technology. Our factory covers tens of thousands of square meters and includes various specialized production and design centers, ensuring efficient operations from design to production and assembly.

☑ Design Center

The design center is equipped with professional vehicle design engineers who are well-versed in customer needs. They provide tailored solutions based on project requirements and perfect every design detail to ensure that the truck or trailer body design meets the highest standards of functionality and safety.

- Composite Panel Production Center

TOPOLO-TRUCK possesses advanced adhesive-bonded composite panel production lines and thermally laminated composite panel production lines, manufacturing various foam core, honeycomb core, and plywood core composite panels. (Skin materials include FRP, aluminum, steel, HPL, PVC, and PET, etc.)

CNC Machining Centers

TOPOLO-TRUCK’s CNC machining centers are a key component of our advanced manufacturing processes. We can customize composite panels to meet customer requirements, whether in custom shape or size, and complete the machining efficiently and precisely.

- Metal Parts Processing Center

TOPOLO-TRUCK has strong metal processing capabilities to manufacture a variety of standard and non-standard parts for trucks and trailers, including hinges, locks, profiles, door frames, subframes, floors, cargo tracks, and kick plates, etc. ensuring precision and quality for every part.

- Assembly Center

The assembly center efficiently and accurately completes the assembly of modular box bodies, ensuring that each box body is assembled in a short period while maintaining high-quality standards.

- Packaging and Shipping

TOPOLO-TRUCK offers customized packaging and shipping solutions to optimize logistics processes, helping users save on shipping costs and minimize unloading challenges.

- All items are carefully packaged using high-quality materials to ensure their safe transport. This minimizes the risk of damage and ensures products arrive at their destination intact.

- Packaging is designed to streamline the unloading process. Each item is carefully packaged and arranged for easy access, requiring minimal manpower and time for unloading, thus ensuring a smooth and efficient delivery process.

Serving the Global Market

TOPOL-TRUCK is committed to providing high-quality service to every user in the international market. Our products are sold in Europe, North America, South America, the Middle East, Southeast Asia, Oceania, and Africa. We work closely with local distributors to provide regional solutions that meet the cultural, economic, and regulatory requirements of each market.

After-Sales Service

TOPOLO-TRUCK is committed to providing comprehensive after-sales support to ensure the seamless operation and longevity of our products. Our after-sales service includes installation guidance, user manuals, and continuous improvement solutions.

Related Products

Product Category

- Aluminum Truck Trays6 products

- Box Trailers5 products

- Dry Freight Truck Bodies18 products

- Refrigerated Truck Bodies27 products

- Truck Accessories15 products

- Truck Body Panels13 products

- Wing Truck Bodies4 products