Durable Insulated Truck & Van Bodies with FRP Sandwich Panels

FRP refrigerated truck bodies excel in cold chain logistics due to their excellent thermal insulation, light weight and durability. TOPOLO-TRUCK is a professional CKD/SKD refrigerated truck body manufacturer. We provide a series of design and manufacturing solutions to meet the application requirements of various industries.

Body Structure Design

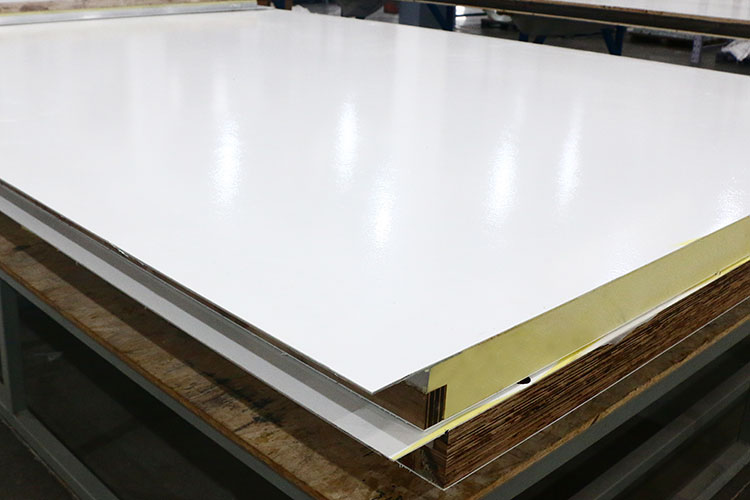

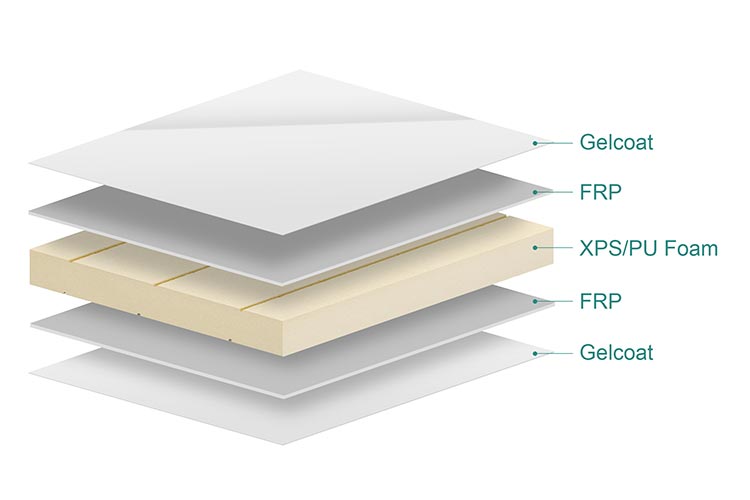

- One-piece composite panels: FRP panels usually adopt one-piece molding technology, with the middle layer of thermal insulation foam and the outer layer of weather-resistant food-grade FRP plate.

- Insulation layer design: The thickness of the thermal insulation panel is generally between 75-100 mm, which is adjusted according to the different requirements of the transported goods to ensure the best thermal insulation performance.

- Seamless connection: Seamless connection technology is used to prevent cold air leakage and improve insulation efficiency.

Body Materials

- FRP facing PU foam sandwich panels.

- FRP facing XPS foam sandwich panels.

Product Features

- Optimized design.

- Quick assembly.

- Thermal insulation.

- Durable.

- Waterproof and moisture-proof.

- Reduce manufacturing costs.

Expert in CKD refrigerated truck body solutions

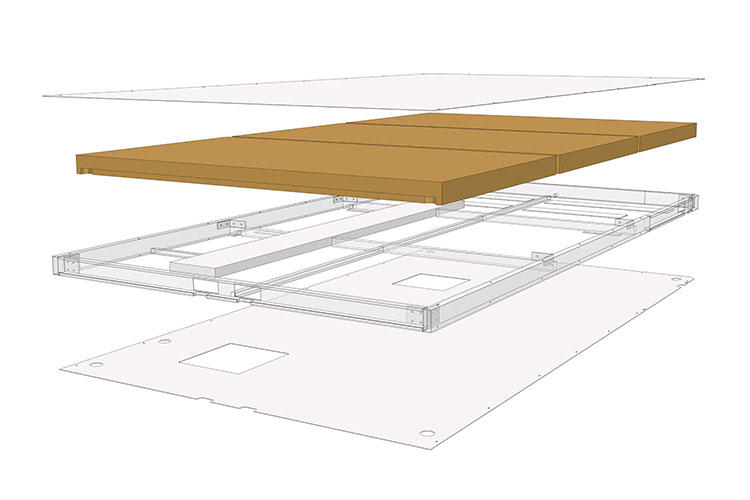

CKD (complete knock-down) refrigerated truck bodies refer to a manufacturing process where they are completely disassembled into parts, then packed and transported to another location for reassembly. This process can reduce transportation and manufacturing costs and promote local employment.

TOPOLO-TRUCK is a unique technology solution company. We have a strong technical R&D team, advanced production factory and efficient service teams, which together build a solid foundation for development. As experts in refrigerated truck bodies, we provide design, material, manufacturing and packaging solutions.

Applications

- Fruits and vegetables.

- Meat and seafood.

- Ice cream.

- Frozen beverages.

- Milk.

- Pharmaceuticals.

- Biological products.

- Sensitive chemicals.

- Flowers and plants.

- Semiconductors.

- Pet transportation.

Fast Assembly, High Efficiency Production

We are committed to making the building of refrigerated truck bodies simpler and easier. All CKD kits are produced on the high-precision production line of our factory and assembled and inspected by experienced engineers. After being transported to the destination by container, the operator can quickly assemble it according to the installation instructions we provide. The entire installation process does not require complex installation tools, only basic lifting equipment and tools such as electric drills, hammers, wrenches, etc. Even unskilled operators can complete the assembly task, and skilled operators can even achieve an efficient productivity of 1 person 1 day 1 vehicle.

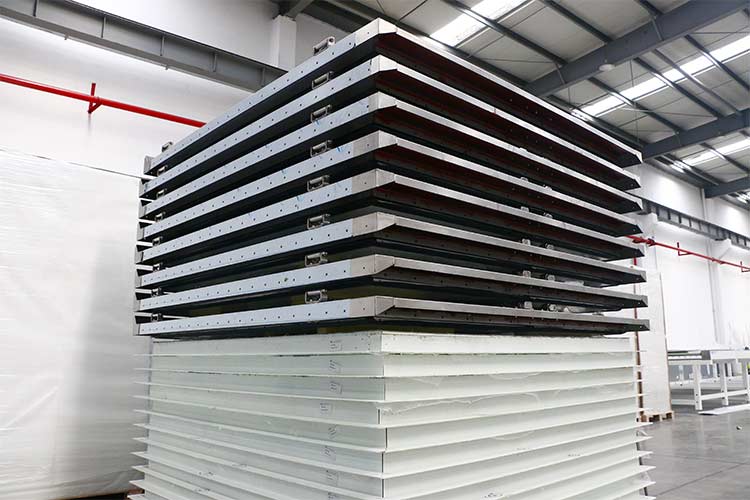

High-quality Thermal Insulation Materials & Advanced Production Technology

- The insulation materials we use are CE certified and meet the environmental protection standards of countries and regions such as Europe, North America, and Australia.

- Using vacuum lamination technology, the skin and the insulation core material are composited under high pressure in a vacuum state.

- Lightweight and waterproof reinforcement materials are embedded inside the insulation material to enhance its structural strength.

Composite Panels for Refrigerated Trucks

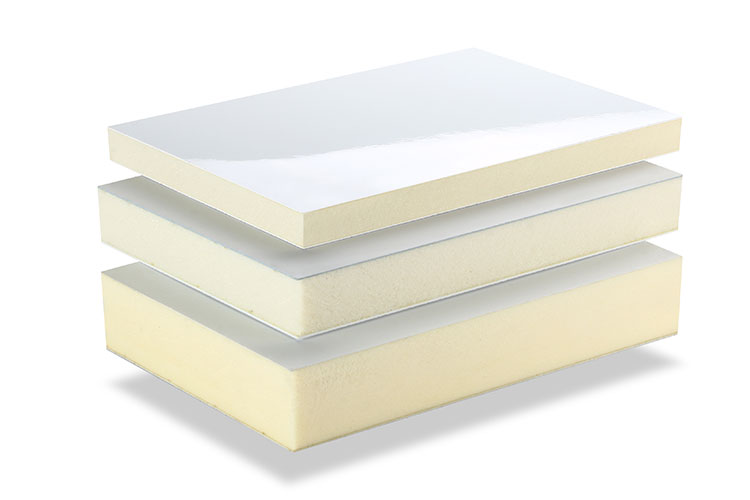

We provide two types of thermal insulation composite panels: XPS (Extruded Polystyrene) and PU (Polyurethane)foam core sandwich panels. Purchasers can choose different specifications such as density and thickness according to application requirements.

XPS Insulation Panels

- Thermal insulation.

- Not easy to deform.

- Lightweight.

- Waterproof.

- Durable.

PU Insulation Panels

- Lightweight.

- Low thermal conductivity.

- Corrosion resistant.

- Waterproof.

- Compression resistant.

- Flame retardant.

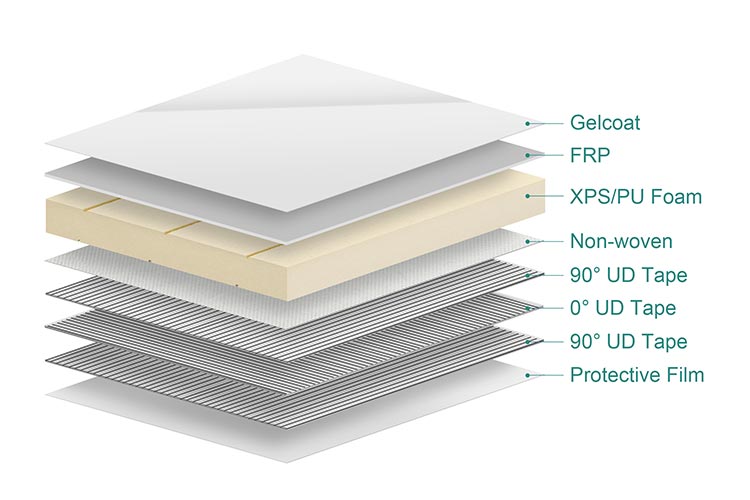

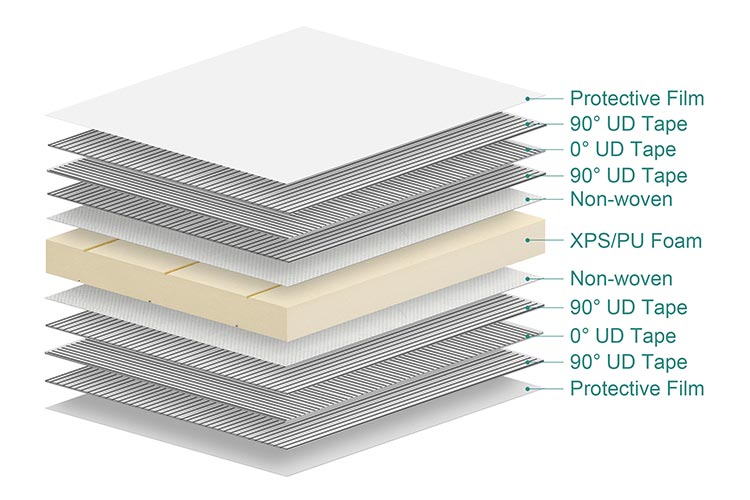

New Materials, Mew technologies

We have developed a new type of thermoplastic FRP sheet – CFRT (Continuous Fiber Reinforced Thermoplastic) to replace the traditional thermosetting FRP sheet, or to mix the two, making the insulation panels more durable and lighter, and greatly reducing the manufacturing cost.

Both sides are UV-resistant gel-coated FRP sheets.

The outer side is made of FRP sheet and the inner side is made of CFRT sheet.

Both sides are continuous fiber reinforced thermoplastic composite sheets.

Our Refrigerated Truck Accessory Kits

We design and manufacture various refrigerated truck parts according to customer needs. Here are some common customized refrigerated truck body parts, such as refrigeration unit, inner partition, rear door, side door, corner cap, edging profile, door lock system, floor, E-track, suspension system, subframe, safety light, bumper, side guard, rear door lift platform, etc.

All Sizes Can Be Customized

TOPOLO-TRUCK production equipment can meet the manufacturing of all types of refrigerated truck bodies. We customize light, medium and heavy duty refrigerated trucks, from mini boxes less than 1 meter to 12 meters. Meet the needs of various industries for refrigerated boxes, whether it is regional distribution within the city or long-distance logistics transportation.

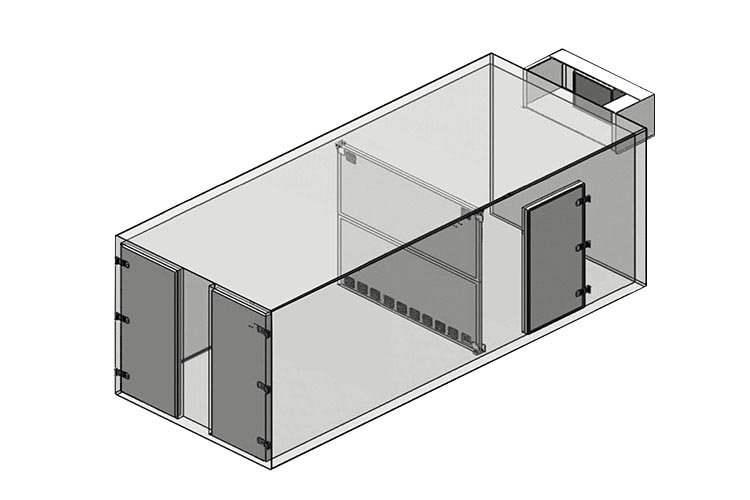

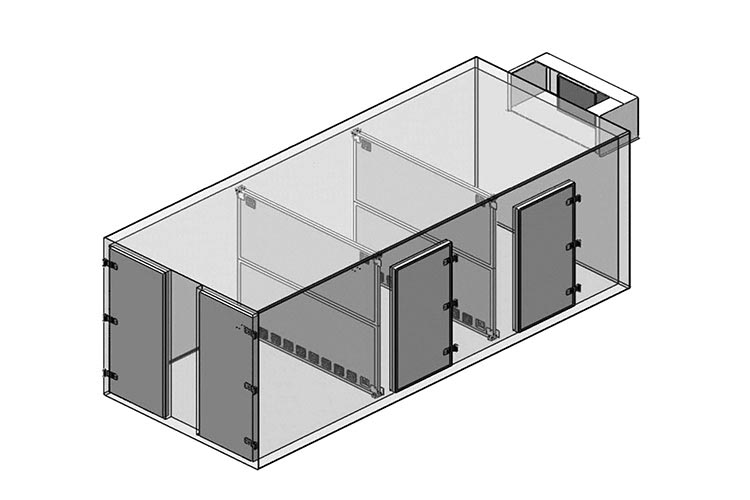

One box, Multiple Temperature Zones

The multi-temperature zone refrigerated truck bodies designed by excellent engineers make up for the shortcomings of traditional refrigerated trucks in transporting a single type of goods, realize the mixed loading of goods with different temperature requirements, improve transportation efficiency and reduce transportation costs. We can build refrigerated truck bodies with two, three and four temperature zones.

Optimize Packaging Solutions

In order to safely deliver the CKD kits to the destination and facilitate buyers to unload the goods simply and quickly, we have designed a reliable packaging solution for each batch of goods to ensure that they are not affected by sea water, rain, ice and snow during long-distance transportation, as well as bumps, collisions, extrusions and other problems during transportation.

Providing the Most Professional Solutions

- 20 years of experience in quantitative truck design and development.

- More than 100 manufacturing team.

- More than 10 international language service teams (English, Russian, French, Spanish, Portuguese, Arabic, German, Italian, Japanese, Korean).

- Cooperating with customers in more than 50 countries and regions.

Related Products

Product Category

- Aluminum Truck Trays6 products

- Box Trailers5 products

- Dry Freight Truck Bodies18 products

- Refrigerated Truck Bodies27 products

- Truck Accessories15 products

- Truck Body Panels13 products

- Wing Truck Bodies4 products