Home >> Truck Composite Panels

How to slim down a truck body? Are you still worried about the bulky truck body? The bulky truck body not only reduces transportation efficiency, consumes more raw materials, but also makes your truck chassis overwhelmed. You should choose lighter materials. Fiberglass PP honeycomb panel is undoubtedly the representative material of lightweight. It has both lightweight and strength, and is corrosion-resistant. Using it as a truck box panel will bring you more economic benefits and safety performance.

Specifications

| Core Material | Polypropylene Honeycomb |

| Skin Material | Thermoset FRP Sheet, Thermoplastic CFRT Sheet |

| Length | ≤12m |

| Width | 50~3200mm |

| Thickness | 9~60mm |

| Density | 60/80/120/160/200kg/m³ |

| Cell Diameter | 6/8/10/12mm |

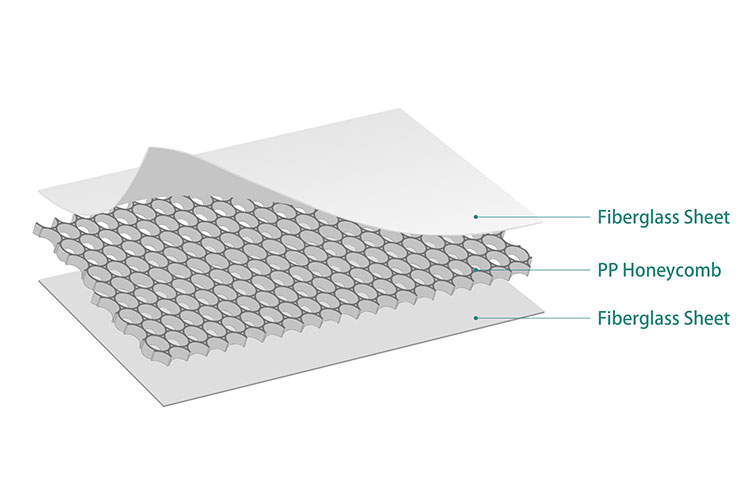

Structure of PP Honeycomb Core Panels

PP honeycomb panel is a three-layer structure composite panel, the middle layer is polypropylene (PP) honeycomb, and the upper and lower layers are fiberglass sheets (FRP/CFRT). It has the advantages of being lightweight, high strength, corrosion resistance, and 100% recyclable.

Which Fiberglass Material to Choose as Surface Material

- FRP materials are harder, and the surface is usually decorated with gelcoat, so it has a more aesthetic effect. Truck boxes with FRP surfaces require more careful maintenance.

- CFRT materials are more tough and rigid and can withstand more external impacts, but the surface is not as smooth and flat as FRP.

Thermoplastic PP Honeycomb Panels

Thermoplastic honeycomb panels are becoming more and more popular among truck body manufacturers due to the following main factors:

- Lightweight and High Strength: under the same weight, it is stronger than thermosetting FRP honeycomb panels, and under the same strength, it is lighter than thermosetting FRP honeycomb panels.

- Thermal Bonding: CFRT skin and PP honeycomb core are thermally fused without glue, and no harmful gas will be generated during processing.

- Environmental Protection: thermoplastic honeycomb core and thermoplastic skin are 100% recyclable, and their service life is longer than that of traditional thermosetting FRP.

Application of Fiberglass Honeycomb Panels in Truck Wall Panels

The installation method of fiberglass PP panels is very simple. Usually, the box can be installed by just using glue and screws to fix the edged profiles, and the easy cutting performance of PP honeycomb panels allows opening holes in the walls or roofs to install other components.

Application of Thermoplastic Honeycomb Panels in Truck Floors

As a new type of truck floor material, anti-skid thermoplastic PP honeycomb panels have excellent properties such as high strength, water-proof, lightweight and wear resistance. They have replaced anti-skid aluminum plates on many vehicles. Especially in dry cargo trucks and dump trucks, it has proven to be a reliable choice.