Home >> Truck Composite Panels

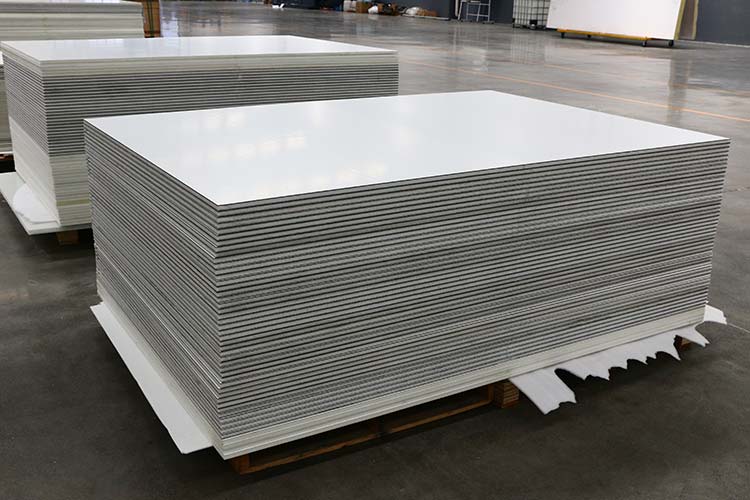

PET foam core sandwich panel is a new type of truck body composite panel, which is mainly used in dry freight trucks. PET foam board is a closed-cell rigid foam that basically does not absorb water, and its strength will increase as its density increases. Compared with the traditional metal truck body, the PET foam core sandwich panel truck body is lighter, has better impact resistance, and has a much longer service life. In addition, PET foam board is a recyclable and environmentally friendly material, which is in line with the concept of sustainable development.

Specifications

| Core | PET Foam Board |

| Skin | Fiberglass, Aluminum, Pre-painted steel, Stainless steel, etc |

| Width | ≤3.2m |

| Thickness | 10~120mm |

| Length | ≤12m |

| Core Density | 50~300 kg/m³ |

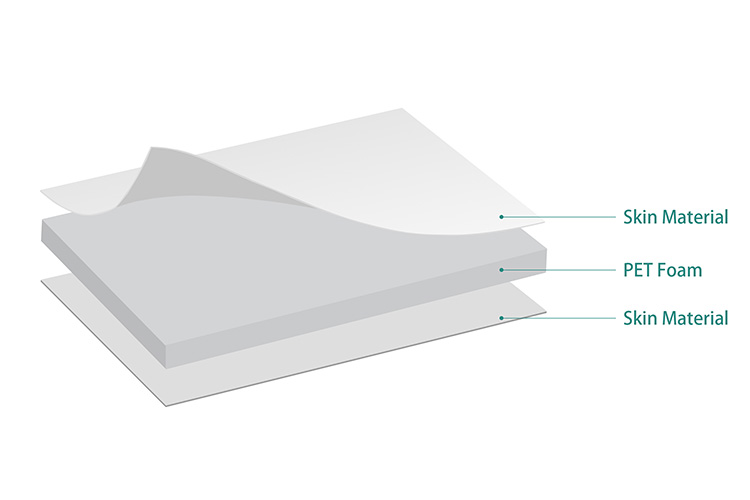

Structure of PET Foam Core Sandwich Panels

PET foam core can be composited with various skin materials such as FRP, aluminum, stainless steel, pre-painted steel, plywood, etc.

Fiberglass Skin PET Foam Sandwich Panels

TOPOLO-TRUCK has developed a new type of skin material – CFRT (Continuous Fiberglass Reinforced Thermoplastic), which is more tough than the thermosetting FRP skin material, so CFRT can be made thinner and lighter while maintaining a higher strength.

Application of PET Sandwich Panels in Box Trucks

Fiberglass PET composite panels can be widely used in dry cargo trucks instead of wooden boards, aluminum panels, or other metal panels. It reduces the weight of the truck box and is easier to clean. With proper maintenance, its service life is not inferior to Box made of aluminum panels.