FRP Truck Bodies

Home >> Truck Bodies

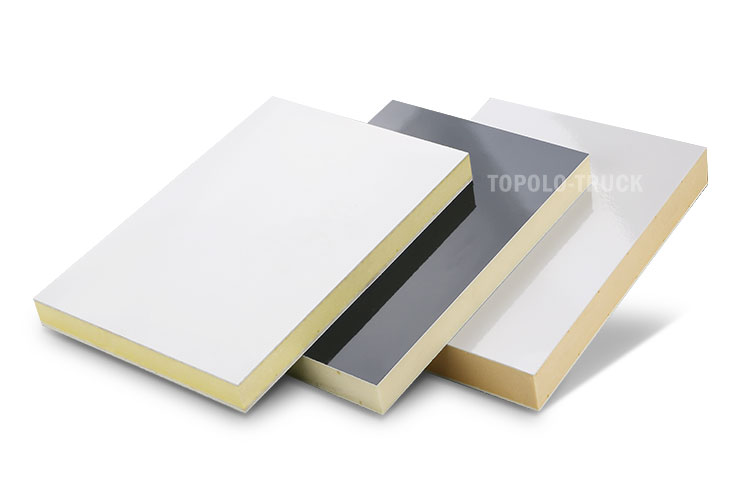

The main material of FRP truck body is FRP sandwich panel, FRP (Fiberglass Reinforced Plastic) is a material with lightweight, strength, toughness, heat insulation, waterproof, smoothness and many other properties. Compared with full metal panels and metal surface sandwich panels, FRP sandwich panels have obvious advantages. It is lighter and more impact-resistant. It is a representative material for lightweight box trucks. FRP composite panels are being used for more and more box truck bodies, whether refrigerated or dry freight. FRP composite panels are generally welcomed by truck manufacturers for their superior performance.

What is FRP Sheets?

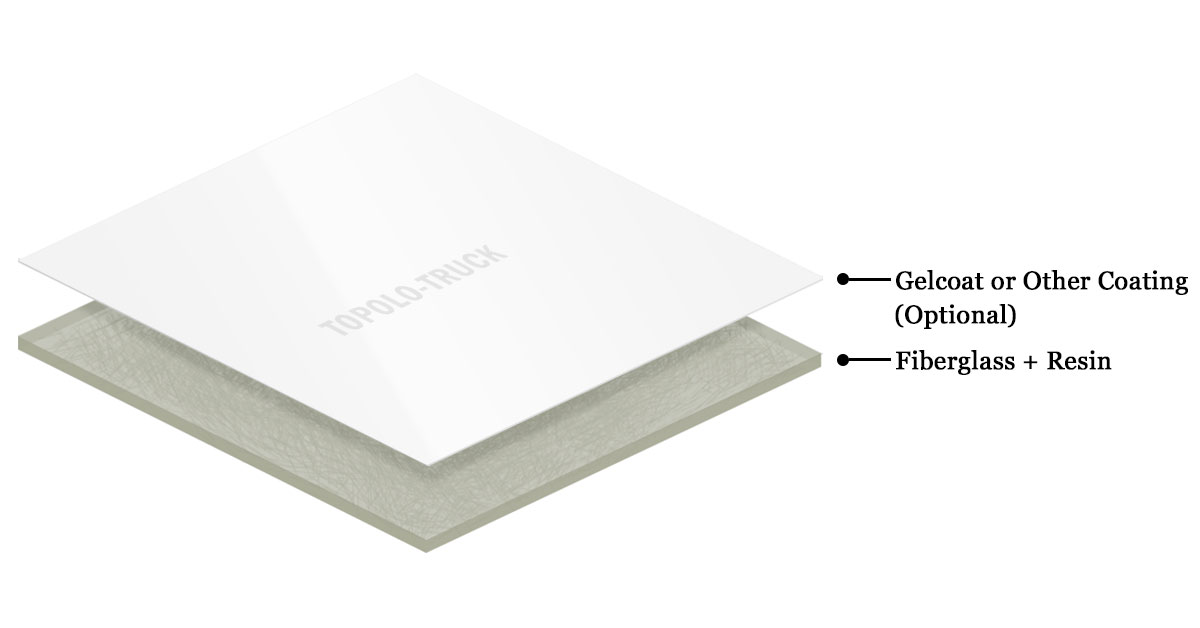

FRP ( fiberglass reinforced plastic), also known as GFRP or GRP, is a reinforced plastic made of resin (unsaturated polyester, epoxy resin, phenolic, etc.) as a matrix and fiberglass as a reinforcing material. It is light and hard, non-conductive, stable in performance, high in mechanical strength and corrosion-resistant.

Types of FRP Sheets

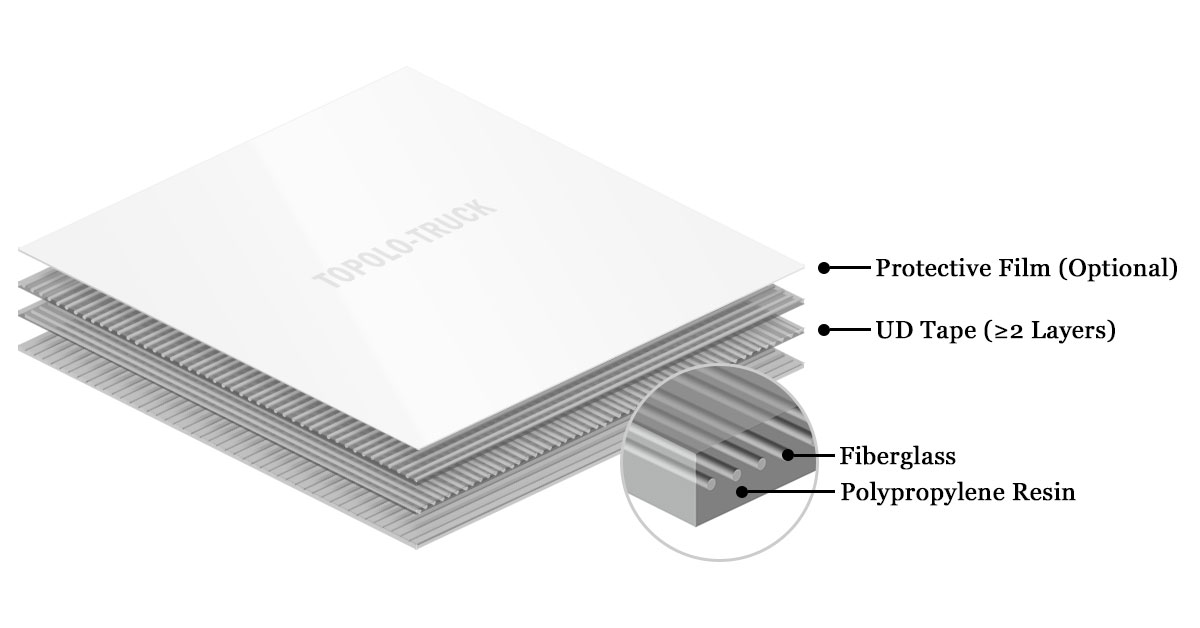

Currently, TOPOLO-TRUCK provides two types of FRP sheets: thermosetting FRP and thermoplastic FRP (CFRT, also called Continuous Fiberglass Reinforced Thermoplastic). These two types of FRP are different resin types and fiberglass types, and they have their own characteristics and applications.

- Its fiberglass type is felt or fabric, the surface is a layer of gel coat, and the thermosetting FRP sheet is more flat and smoother.

- It is laminated with multiple layers of continuous fiberglass unidirectional prepreg tape, so it is stronger and more resilient, and the sheets can be made thinner.

How to Choose the Core Material for FRP Sandwich Panels?

FRP is compatible with a variety of foam (XPS/PU/PET/PVC) and cellular (PP) systems, and which FRP composite material to choose for truck bodies depends on the vehicle’s use. TOPOLO-TRUCK supplies three types of FRP sandwich panels: foam core sandwich panels, honeycomb core sandwich panels, and plywood sandwich panels.

Applications

- FRP foam core panels, such as XPS/PU sandwich panels, are commonly used in the production of refrigerated truck bodies due to their excellent thermal insulation properties, for transporting fresh vegetables, meat, frozen drinks, ice cream, pharmaceuticals, and other products.

- PVC/PET foam core sandwich panels and PP honeycomb core panels, on the other hand, are primarily used in the production of dry cargo truck bodies due to their high strength and lightweight characteristics.

TOPOLO-TRUCK

The Expert in FRP Composite Box

TOPOLO-TRUCK has developed a range of high-quality FRP composite panels for truck and trailer bodies. Our composite panels perfectly combine strength, quality, aesthetics, and environmental requirements to help you improve your truck’s durability, safety, and transport efficiency. Using industry-leading materials and technologies, we meticulously craft and deliver optimal solutions to meet the stringent standards of your vehicle projects, providing high-quality products that exceed customer expectations.

Customized Services

FRP Sandwich Panels

- TOPOLO-TRUCK not only operates its own FRP sandwich panel manufacturing facility, but also provides professional design services. We are committed to developing optimal solutions tailored to each customer’s specific application requirements, while minimizing overall construction costs as much as possible without compromising performance and durability.

Box Body Accessories

- In addition, TOPOLO-TRUCK offers complete truck body CKD / SKD kits, supplying a full range of components required for truck body assembly, including door locks, hinges, wind hooks, lighting systems, bumpers, subframes, and other related parts. This integrated supply capability ensures high compatibility, easy installation, and efficient assembly for our customers.

Assembly

We offer both pre-assembled kits (CKD / SKD) and fully assembled units to meet different customer requirements. Pre-assembled kits facilitate transportation and on-site installation, effectively reducing logistics and tariff costs. Fully assembled units, on the other hand, are ready to use upon delivery.

Case

4.2m Refrigerated Truck Box

This is an insulated box designed for food transportation. The body is constructed from 100 mm thick gelcoat FRP sandwich panels with a polyurethane foam core, providing excellent thermal insulation performance. It is strong and durable, outperforming most refrigerated truck bodies currently on the market.

With an attractive appearance, the gelcoat-coated FRP panels give the surface a smooth and refined finish. Its outstanding performance allows it to easily withstand relatively high-temperature and high-humidity environments, keeping food fresh and extending its shelf life.