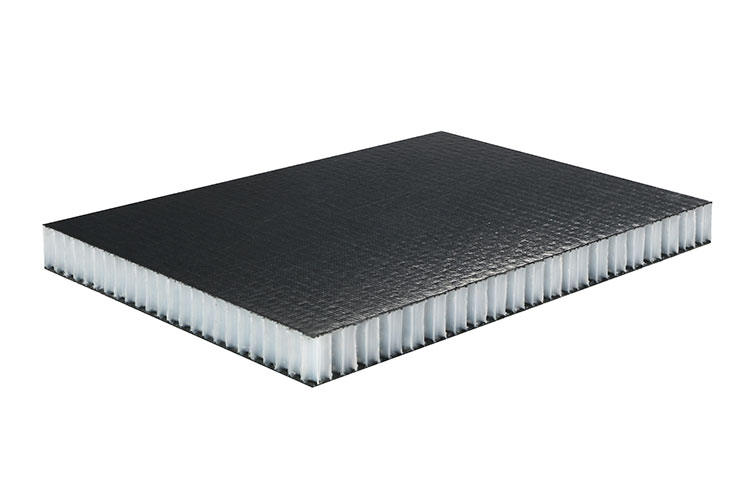

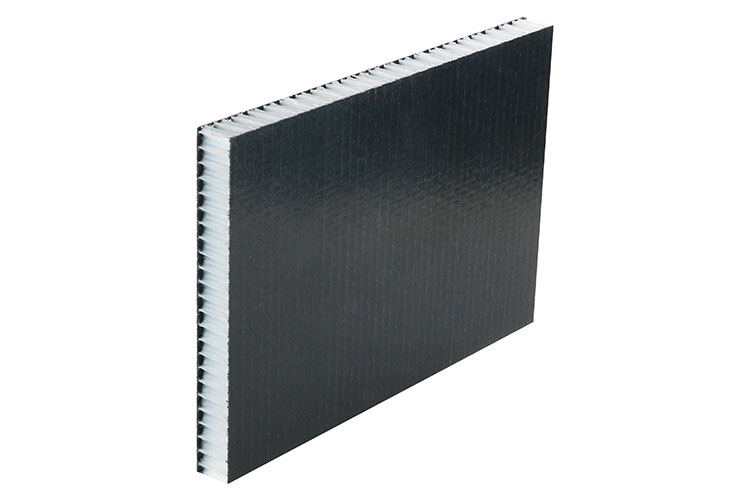

Thermoplastic honeycomb composite panels are sandwich panels with CFRT (continuous fiber reinforced thermoplastic) composite sheets on the surface. Since no glue is used during the processing, the bonding between the layers is tighter and the structure is more stable. Our thermoplastic honeycomb composite panels are designed to meet the stringent requirements of modern transportation and are designed to provide unparalleled quality and performance for your light truck applications.

Product Features

- Impact-resistant.

- Corrosion-resistant.

- Easy to process.

- High structural strength.

- Lower cost.

Specifications

- Top Facing: CFRT Sheet. (Thickness: 0.7~2.0mm)

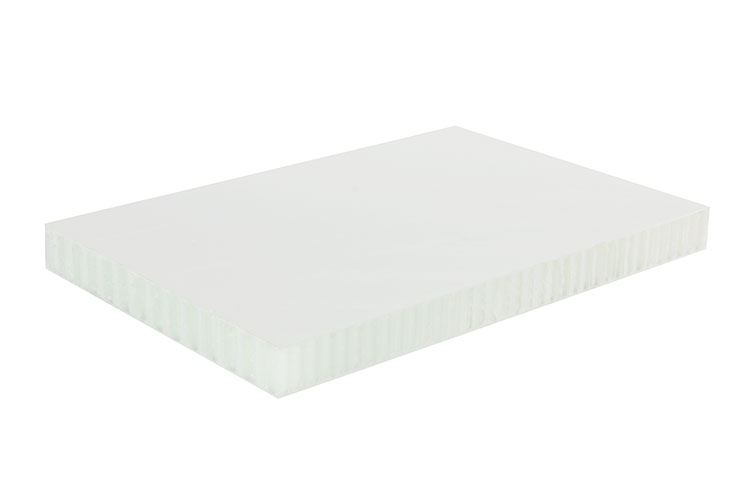

- Core Materials: PP (Polypropylene) honeycomb. (Density: 60~160kg/m³)

- Bottom Facing: CFRT Sheet. (Thickness: 0.7~2.0mm)

- Width: Max 3.2m.

- Length: Max 12m.

- Thickness: 10~150mm.

Professional thermoplastic honeycomb panel manufacturer

We can also provide different surface treatments for thermoplastic PP honeycomb panels to meet different application requirements, such as UV resistance, anti-slip, lamination, painting, etc. We have an advanced fully automatic thermoplastic honeycomb panel production line and are currently the largest and most technologically advanced producer in China.

Description

Expert in Truck Body Composite Panels

TOPOLO-TRUCK has developed a series of high-quality composite panels for box truck bodies. Our composite panels are designed to perfectly combine strength, quality, aesthetics and environmental protection requirements, which can help you improve the durability, safety and transportation efficiency of your trucks. We use industry-leading materials and technologies to carefully build and provide the best solutions for your vehicle projects, and provide high-quality products that meet strict standards and exceed customer expectations.

Materials and Applications

| Core | Facing | Applications |

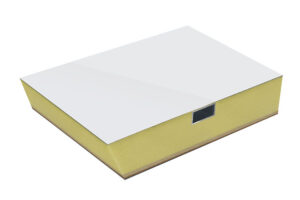

| XPS (Extruded polystyrene) Foam | FRP Sheet, CFRT Sheet. | Refrigerated Trucks, Dry Freight Trucks. |

| PU (Polyurethane) Foam | FRP Sheet, CFRT Sheet. | Refrigerated Trucks |

| PET (Polyethylene Terephthalate) Foam | FRP Sheet, CFRT Sheet, Aluminum Sheet, ACP Panel. | Dry Freight Trucks |

| PVC (Polyvinyl chloride) Foam | FRP Sheet, CFRT Sheet, ACP Panel. | Refrigerated Trucks, Dry Freight Trucks. |

| PP (Polypropylene) Honeycomb | FRP Sheet, CFRT Sheet. | Dry Freight Trucks |

| HDPE(High-density Polyethylene) Plastic | Galvanized Steel Sheet, Aluminum Sheet. | Dry Cargo Trailers |

| Plywood | FRP Sheet, CFRT Sheet. | Dry Freight Trucks |

Note

- FRP: Fiberglass reinforced.

- CFRT: Continuous fiber reinforced thermoplastic.

- ACP: Aluminum Composite Panel.

Composite Panel Production Lines

We have multiple one-piece composite panel production lines that can meet vacuum adhesive composite and thermoplastic composite production. The panel size can be up to 12m long and 3.2m wide.

CNC Machining

The composite panels are processed into designed shapes at high speed and high precision on large CNC processing platforms, and the panels in the same batch can maintain consistent precision.

Accessories Services

Provide standard and non-standard parts to meet special application requirements. Including sheet metal processing, laser welding, aluminum profile processing, metal casting processing, etc.

Truck Body CKD/SKD Services

TOPOLO-TRUCK provides box truck bodies in the form of CKD (Completely Knock Down) and SKD (Semi-Knocked Down), and provides optimized design services.